Cross-linked polyethylene (PEX) offers enhanced thermal resistance, superior durability, and improved chemical stability compared to linear polyethylene, making it ideal for high-performance plumbing and heating applications. Unlike linear polyethylene, PEX features a networked molecular structure that significantly increases its mechanical strength and flexibility. This structural difference allows PEX to maintain integrity under extreme temperature variations and pressure, providing long-term reliability in demanding environments.

Table of Comparison

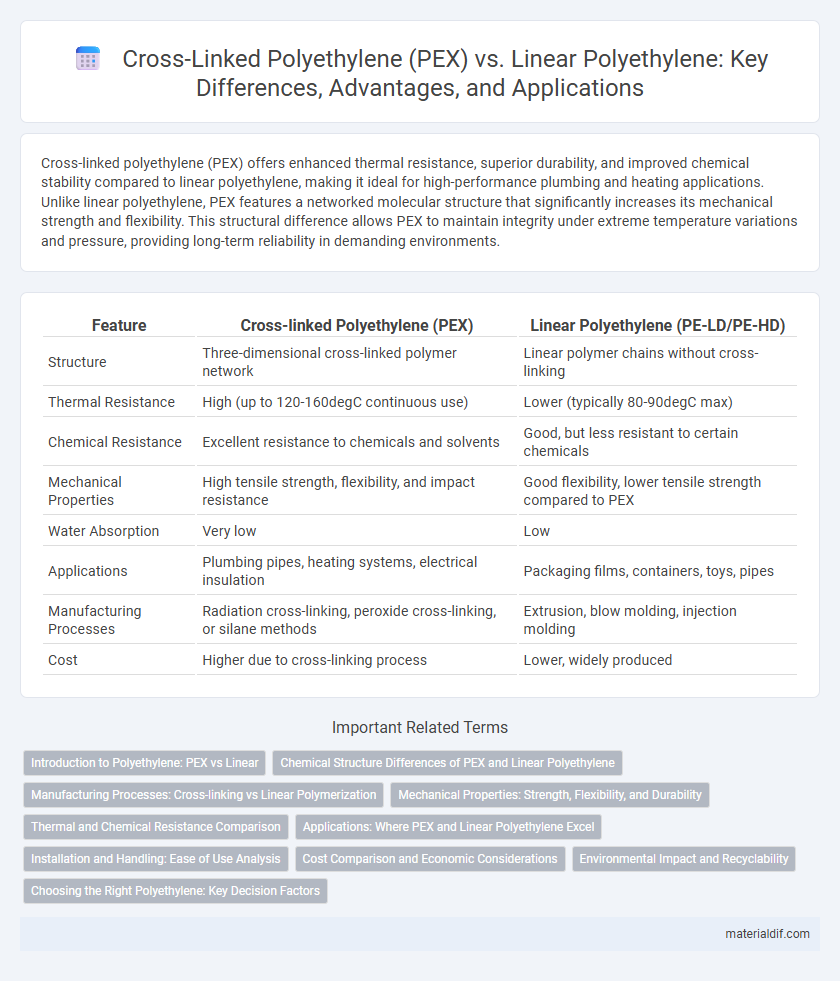

| Feature | Cross-linked Polyethylene (PEX) | Linear Polyethylene (PE-LD/PE-HD) |

|---|---|---|

| Structure | Three-dimensional cross-linked polymer network | Linear polymer chains without cross-linking |

| Thermal Resistance | High (up to 120-160degC continuous use) | Lower (typically 80-90degC max) |

| Chemical Resistance | Excellent resistance to chemicals and solvents | Good, but less resistant to certain chemicals |

| Mechanical Properties | High tensile strength, flexibility, and impact resistance | Good flexibility, lower tensile strength compared to PEX |

| Water Absorption | Very low | Low |

| Applications | Plumbing pipes, heating systems, electrical insulation | Packaging films, containers, toys, pipes |

| Manufacturing Processes | Radiation cross-linking, peroxide cross-linking, or silane methods | Extrusion, blow molding, injection molding |

| Cost | Higher due to cross-linking process | Lower, widely produced |

Introduction to Polyethylene: PEX vs Linear

Cross-linked polyethylene (PEX) features a networked molecular structure that enhances its thermal stability, chemical resistance, and mechanical properties compared to linear polyethylene. Linear polyethylene, such as high-density polyethylene (HDPE), consists of long, unbranched polymer chains that provide excellent rigidity and tensile strength but lower temperature tolerance than PEX. PEX is widely used in plumbing and radiant heating systems due to its flexibility and durability, while linear polyethylene remains common in packaging and containers due to its stiffness and processability.

Chemical Structure Differences of PEX and Linear Polyethylene

Cross-linked polyethylene (PEX) features a three-dimensional network formed through covalent cross-links between polymer chains, which enhances its thermal and mechanical properties. In contrast, linear polyethylene consists of long, unbranched polymer chains without cross-linking, resulting in more flexible and less thermally stable material. The chemical structure of PEX restricts molecular mobility, improving resistance to deformation and chemical exposure compared to the linear form.

Manufacturing Processes: Cross-linking vs Linear Polymerization

Cross-linked polyethylene (PEX) undergoes a specialized cross-linking process where molecular chains are chemically bonded using methods like peroxide cross-linking, silane cross-linking, or electron beam irradiation, which enhances thermal resistance and mechanical strength. In contrast, linear polyethylene is produced through linear polymerization techniques such as Ziegler-Natta or metallocene catalysis, resulting in a straightforward molecular structure with lower density and crystallinity. The manufacturing difference significantly impacts material properties, with PEX offering improved durability and flexibility for applications requiring heat and chemical resistance.

Mechanical Properties: Strength, Flexibility, and Durability

Cross-linked Polyethylene (PEX) exhibits superior mechanical properties compared to Linear Polyethylene due to its cross-linked molecular structure, which enhances tensile strength, flexibility, and resistance to deformation. The networked bonds in PEX provide improved thermal stability and durability, making it ideal for demanding applications like plumbing and radiant heating systems. In contrast, Linear Polyethylene, particularly High-Density Polyethylene (HDPE), offers good strength and flexibility but lacks the same level of resilience and long-term durability under stress and temperature variations.

Thermal and Chemical Resistance Comparison

Cross-linked polyethylene (PEX) exhibits superior thermal stability compared to linear polyethylene, withstanding continuous operating temperatures up to 120degC, whereas linear polyethylene typically degrades at around 80-90degC. Chemically, PEX demonstrates enhanced resistance to oxidation and solvent exposure due to its three-dimensional cross-linked structure, contrasting with the more susceptible linear polymer chains of linear polyethylene. This makes PEX the preferred choice in plumbing and heating applications where elevated temperature and chemical durability are critical.

Applications: Where PEX and Linear Polyethylene Excel

Cross-linked Polyethylene (PEX) excels in plumbing, radiant heating, and electrical insulation due to its enhanced thermal resistance, chemical stability, and flexibility. Linear Polyethylene, including High-Density Polyethylene (HDPE), is ideal for packaging, containers, and piping systems demanding high tensile strength and impact resistance. PEX's cross-linked molecular structure allows superior durability in high-temperature environments, whereas Linear Polyethylene offers cost-effective solutions with excellent moisture barrier properties.

Installation and Handling: Ease of Use Analysis

Cross-linked polyethylene (PEX) offers superior flexibility and heat resistance compared to linear polyethylene (PE-LD or PE-HD), making it easier to handle and install in complex plumbing systems. PEX's enhanced cross-linking results in improved durability, allowing for fewer fittings and faster assembly, which reduces labor costs and installation time. Linear polyethylene, while more rigid and less heat-resistant, is simpler to recycle but often requires more fittings and careful handling during installation due to its lower flexibility.

Cost Comparison and Economic Considerations

Cross-linked polyethylene (PEX) typically incurs higher initial costs than linear polyethylene due to its complex manufacturing process and enhanced thermal and mechanical properties. Economic considerations favor PEX in long-term applications such as plumbing and radiant heating systems, where durability and resistance to deformation reduce maintenance expenses. Linear polyethylene remains cost-effective for mass production of packaging and plastic films, where budget constraints prioritize upfront material price over extended lifespan benefits.

Environmental Impact and Recyclability

Cross-linked polyethylene (PEX) features a three-dimensional network structure that enhances durability but significantly reduces its recyclability compared to linear polyethylene (PE), which consists of linear chains more easily processed in recycling systems. The cross-linking in PEX complicates thermal recycling methods, often leading to landfill disposal or incineration, whereas linear polyethylene is widely recyclable and has a lower environmental footprint due to efficient reuse in manufacturing. Consequently, linear polyethylene supports a circular economy model, whereas PEX's environmental impact is higher due to limited recyclability and more challenging end-of-life recovery options.

Choosing the Right Polyethylene: Key Decision Factors

Cross-linked polyethylene (PEX) offers superior thermal resistance, chemical stability, and flexibility compared to linear polyethylene, making it ideal for plumbing and heating applications. Linear polyethylene, including HDPE and LDPE, provides excellent tensile strength, impact resistance, and easy processing for packaging and piping solutions. Key decision factors include the intended temperature range, mechanical stress requirements, and environmental exposure to ensure optimal material performance and longevity.

Cross-linked Polyethylene (PEX) vs Linear Polyethylene Infographic

materialdif.com

materialdif.com