Biodegradable polyethylene offers an eco-friendly alternative to conventional polyethylene by breaking down more rapidly in natural environments, reducing plastic pollution and landfill waste. Unlike traditional polyethylene, which can persist for hundreds of years, biodegradable variants incorporate additives or blend with natural polymers to initiate decomposition under specific conditions. This innovation helps mitigate environmental impact while maintaining the versatile properties of polyethylene in packaging and consumer goods.

Table of Comparison

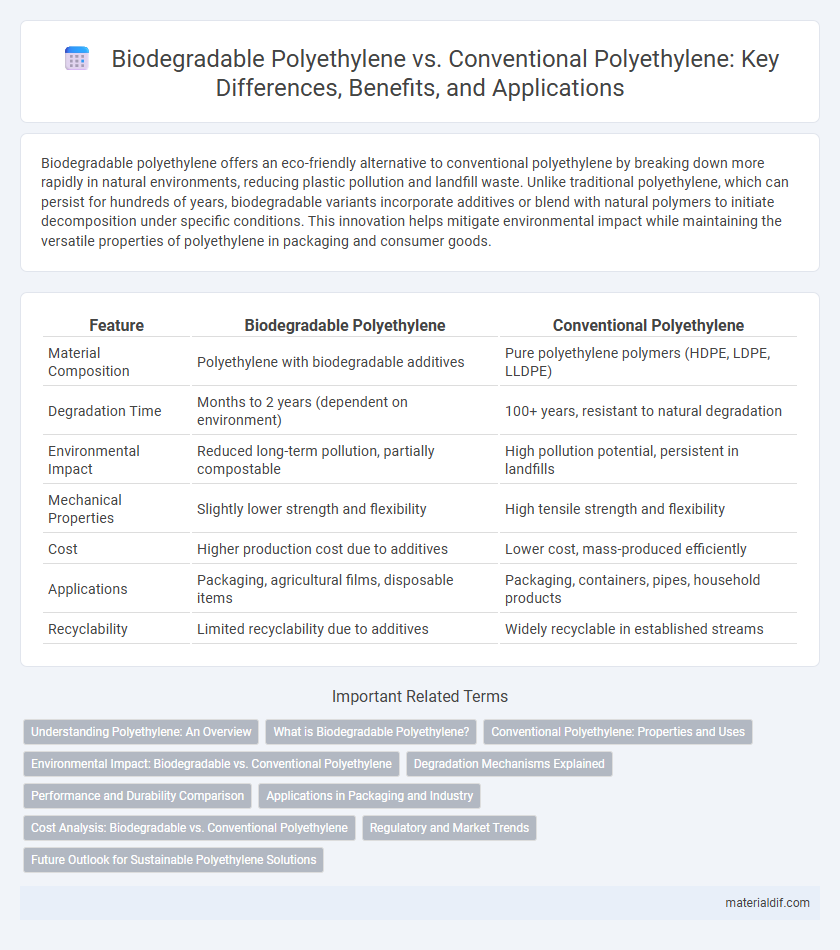

| Feature | Biodegradable Polyethylene | Conventional Polyethylene |

|---|---|---|

| Material Composition | Polyethylene with biodegradable additives | Pure polyethylene polymers (HDPE, LDPE, LLDPE) |

| Degradation Time | Months to 2 years (dependent on environment) | 100+ years, resistant to natural degradation |

| Environmental Impact | Reduced long-term pollution, partially compostable | High pollution potential, persistent in landfills |

| Mechanical Properties | Slightly lower strength and flexibility | High tensile strength and flexibility |

| Cost | Higher production cost due to additives | Lower cost, mass-produced efficiently |

| Applications | Packaging, agricultural films, disposable items | Packaging, containers, pipes, household products |

| Recyclability | Limited recyclability due to additives | Widely recyclable in established streams |

Understanding Polyethylene: An Overview

Polyethylene, a widely used thermoplastic polymer, exists in both conventional and biodegradable forms, each serving distinct environmental roles. Conventional polyethylene, derived from petrochemicals, is durable but poses long-term environmental concerns due to its resistance to natural degradation. In contrast, biodegradable polyethylene incorporates additives or biological components enabling partial breakdown under specific conditions, offering a more sustainable alternative while maintaining similar functional properties.

What is Biodegradable Polyethylene?

Biodegradable polyethylene is a type of polyethylene designed to break down more quickly in the environment through the action of microorganisms, typically incorporating additives that promote biodegradation. Unlike conventional polyethylene, which resists natural decomposition and can persist for hundreds of years, biodegradable polyethylene aims to reduce plastic pollution by accelerating degradation under specific conditions. This material retains the essential properties of conventional polyethylene while enhancing environmental sustainability by facilitating faster breakdown in composting or landfill environments.

Conventional Polyethylene: Properties and Uses

Conventional polyethylene, a widely used thermoplastic polymer, is characterized by its high tensile strength, chemical resistance, and excellent durability, making it suitable for various industrial applications. Its versatility in forms such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE) supports uses ranging from packaging materials and containers to pipes and household goods. Despite its environmental persistence, conventional polyethylene remains preferred in manufacturing due to its cost-effectiveness, mechanical properties, and long-lasting performance.

Environmental Impact: Biodegradable vs. Conventional Polyethylene

Biodegradable polyethylene decomposes more rapidly under specific environmental conditions, reducing long-term plastic pollution and landfill accumulation compared to conventional polyethylene, which can persist for hundreds of years. Conventional polyethylene's resistance to biodegradation leads to widespread microplastic contamination affecting marine and terrestrial ecosystems. Advanced biodegradation pathways in biodegradable polyethylene result in lower carbon footprints and decreased environmental toxicity.

Degradation Mechanisms Explained

Biodegradable polyethylene incorporates additives that trigger oxidative or enzymatic degradation, resulting in polymer chain scission when exposed to environmental factors like ultraviolet light, heat, or microbial activity. Conventional polyethylene, composed solely of long hydrocarbon chains, resists natural degradation due to its high molecular weight and hydrophobic properties, leading to environmental persistence. Understanding these distinct degradation mechanisms highlights the potential environmental benefits of biodegradable polyethylene compared to conventional variants.

Performance and Durability Comparison

Biodegradable polyethylene offers comparable mechanical strength and flexibility to conventional polyethylene, but it decomposes under specific environmental conditions, reducing long-term persistence in ecosystems. Conventional polyethylene exhibits superior resistance to environmental degradation, providing higher durability for applications requiring extended lifespan and structural integrity. Performance trade-offs include biodegradability benefits versus longevity and stability in demanding uses such as packaging and automotive components.

Applications in Packaging and Industry

Biodegradable polyethylene offers enhanced environmental benefits in packaging applications by breaking down more rapidly under composting conditions compared to conventional polyethylene, which persists in the environment for hundreds of years. In industrial uses, biodegradable variants are increasingly adopted for single-use products such as agricultural films and disposable containers, reducing plastic waste accumulation. Conventional polyethylene remains dominant in long-term packaging and heavy-duty industrial applications due to its superior mechanical strength and chemical resistance.

Cost Analysis: Biodegradable vs. Conventional Polyethylene

Biodegradable polyethylene typically incurs higher production costs due to specialized raw materials and processing technologies compared to conventional polyethylene, which benefits from established large-scale manufacturing efficiencies. The market price for biodegradable variants often reflects these increased expenses, impacting overall cost competitiveness in packaging and disposable products. However, evolving regulations and consumer demand for sustainable alternatives may influence economies of scale, gradually narrowing the cost gap between biodegradable and conventional polyethylene.

Regulatory and Market Trends

Biodegradable polyethylene is gaining traction due to stricter regulatory policies aimed at reducing plastic pollution, with the European Union and California leading in bans on single-use conventional polyethylene products. Market trends indicate a surge in demand for biodegradable polyethylene driven by increased consumer awareness and corporate sustainability commitments, while conventional polyethylene remains dominant due to lower production costs and widespread infrastructure compatibility. Regulatory frameworks increasingly incentivize biodegradable alternatives through subsidies and eco-label certifications, positioning them for accelerated growth in both packaging and agricultural sectors.

Future Outlook for Sustainable Polyethylene Solutions

Biodegradable polyethylene offers promising advancements in reducing long-term environmental impact compared to conventional polyethylene, which persists for centuries in landfills. Innovations in bio-based feedstocks and improved degradation mechanisms are accelerating the shift toward more sustainable polyethylene alternatives. Market trends indicate growing investment in biodegradable formulations to meet stricter regulatory standards and increasing consumer demand for eco-friendly packaging solutions.

Biodegradable Polyethylene vs Conventional Polyethylene Infographic

materialdif.com

materialdif.com