Low-Density Polyethylene (LDPE) features a highly branched polymer structure, resulting in a softer, more flexible material with lower tensile strength and higher impact resistance. Linear Low-Density Polyethylene (LLDPE) has a more linear structure with short, uniform branches, offering greater tensile strength, improved puncture resistance, and better flexibility. Both materials are used in packaging, but LLDPE provides superior durability and stretchability, making it ideal for applications requiring toughness and elasticity.

Table of Comparison

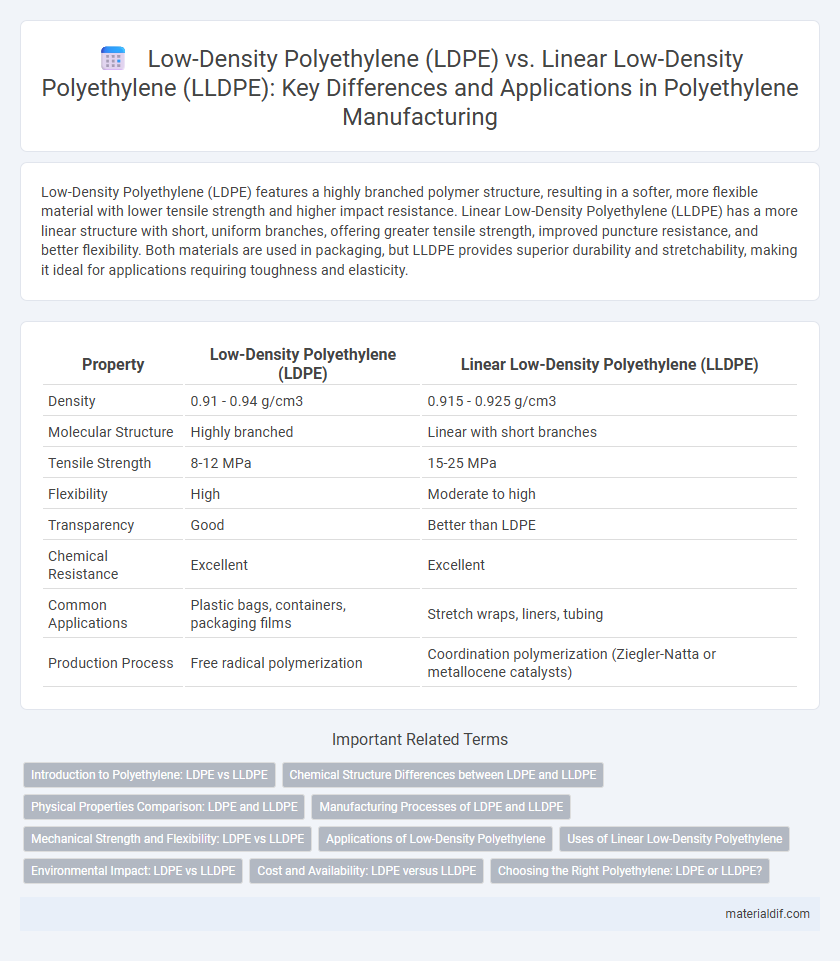

| Property | Low-Density Polyethylene (LDPE) | Linear Low-Density Polyethylene (LLDPE) |

|---|---|---|

| Density | 0.91 - 0.94 g/cm3 | 0.915 - 0.925 g/cm3 |

| Molecular Structure | Highly branched | Linear with short branches |

| Tensile Strength | 8-12 MPa | 15-25 MPa |

| Flexibility | High | Moderate to high |

| Transparency | Good | Better than LDPE |

| Chemical Resistance | Excellent | Excellent |

| Common Applications | Plastic bags, containers, packaging films | Stretch wraps, liners, tubing |

| Production Process | Free radical polymerization | Coordination polymerization (Ziegler-Natta or metallocene catalysts) |

Introduction to Polyethylene: LDPE vs LLDPE

Low-Density Polyethylene (LDPE) is characterized by its highly branched polymer chains, resulting in a flexible, translucent material with excellent impact resistance and low tensile strength. Linear Low-Density Polyethylene (LLDPE) features short, uniform branches, leading to higher tensile strength, superior puncture resistance, and better environmental stress crack resistance compared to LDPE. Both LDPE and LLDPE serve critical roles in packaging, plastic bags, and film applications, with LLDPE favored for stretch films and LDPE for softer, more pliable products.

Chemical Structure Differences between LDPE and LLDPE

Low-Density Polyethylene (LDPE) features a highly branched chemical structure with significant long and short chain branching, resulting in lower density and crystallinity. In contrast, Linear Low-Density Polyethylene (LLDPE) possesses a linear backbone with short, uniform branches introduced by copolymerizing ethylene with alpha-olefins, enhancing tensile strength and flexibility. These structural differences impact properties such as tensile strength, clarity, and resistance to environmental stress cracking.

Physical Properties Comparison: LDPE and LLDPE

Low-Density Polyethylene (LDPE) exhibits a branched polymer structure that results in lower density and higher flexibility compared to Linear Low-Density Polyethylene (LLDPE), which has a linear structure with short branches enhancing tensile strength and impact resistance. LDPE typically has a density range of 0.91-0.93 g/cm3, whereas LLDPE density ranges from 0.915 to 0.925 g/cm3, influencing their mechanical characteristics. The higher crystallinity in LLDPE contributes to greater stiffness and better puncture resistance, making it preferable for applications requiring stronger films and packaging materials.

Manufacturing Processes of LDPE and LLDPE

Low-Density Polyethylene (LDPE) is produced using high-pressure free radical polymerization, resulting in a highly branched polymer structure that imparts flexibility and toughness. Linear Low-Density Polyethylene (LLDPE) is manufactured through copolymerization of ethylene with alpha-olefins using Ziegler-Natta or metallocene catalysts under low-pressure conditions, creating a linear polymer with short, uniform branches that enhance tensile strength and clarity. The distinct polymerization methods directly influence the molecular architecture and performance characteristics of LDPE and LLDPE.

Mechanical Strength and Flexibility: LDPE vs LLDPE

Low-Density Polyethylene (LDPE) exhibits lower tensile strength and higher flexibility due to its highly branched polymer structure, making it ideal for applications requiring softness and elasticity. Linear Low-Density Polyethylene (LLDPE) has a more linear structure with short, uniform branches, resulting in greater mechanical strength and improved puncture resistance while maintaining good flexibility. The enhanced toughness of LLDPE makes it preferable for heavy-duty films and packaging compared to the more pliable LDPE used in squeeze bottles and plastic bags.

Applications of Low-Density Polyethylene

Low-Density Polyethylene (LDPE) is widely used in packaging applications such as plastic bags, films, and containers due to its flexibility, transparency, and moisture resistance. Its low tensile strength and high ductility make LDPE ideal for products requiring easy sealing and flexibility. Unlike Linear Low-Density Polyethylene (LLDPE), LDPE is preferred for applications needing high clarity and softness.

Uses of Linear Low-Density Polyethylene

Linear Low-Density Polyethylene (LLDPE) is primarily used in flexible packaging, such as plastic bags, stretch films, and containers, due to its superior tensile strength and puncture resistance compared to Low-Density Polyethylene (LDPE). LLDPE's enhanced mechanical properties make it ideal for industrial applications requiring durability, including agricultural films and packaging wraps. The polymer's ability to be easily blown into thin films also contributes to its widespread use in consumer goods packaging.

Environmental Impact: LDPE vs LLDPE

Low-Density Polyethylene (LDPE) and Linear Low-Density Polyethylene (LLDPE) differ in environmental impact due to their production processes and recyclability; LDPE is generally easier to recycle but has a higher carbon footprint because of its branched polymer structure. LLDPE, with its linear chains and copolymerization, offers better strength and durability, leading to less material usage but complicates recycling streams. Both types contribute to plastic pollution, yet advancements in chemical recycling and biodegradable additives aim to mitigate their ecological footprint.

Cost and Availability: LDPE versus LLDPE

Low-Density Polyethylene (LDPE) generally costs more than Linear Low-Density Polyethylene (LLDPE) due to its more complex manufacturing process and lower production volumes. Availability of LLDPE is higher as it is widely produced for applications requiring greater strength and flexibility, making it more accessible in various markets. The cost-effectiveness and widespread availability of LLDPE make it a preferred choice for packaging films and industrial uses compared to LDPE.

Choosing the Right Polyethylene: LDPE or LLDPE?

Low-Density Polyethylene (LDPE) offers excellent flexibility and impact resistance, making it ideal for applications like plastic bags and film wraps where softness and clarity are important. Linear Low-Density Polyethylene (LLDPE) provides superior tensile strength and puncture resistance due to its linear structure with short branches, suitable for heavy-duty packaging and stretch films. Selecting between LDPE and LLDPE depends on the required durability, flexibility, and environmental resistance of the intended product.

Low-Density Polyethylene vs Linear Low-Density Polyethylene Infographic

materialdif.com

materialdif.com