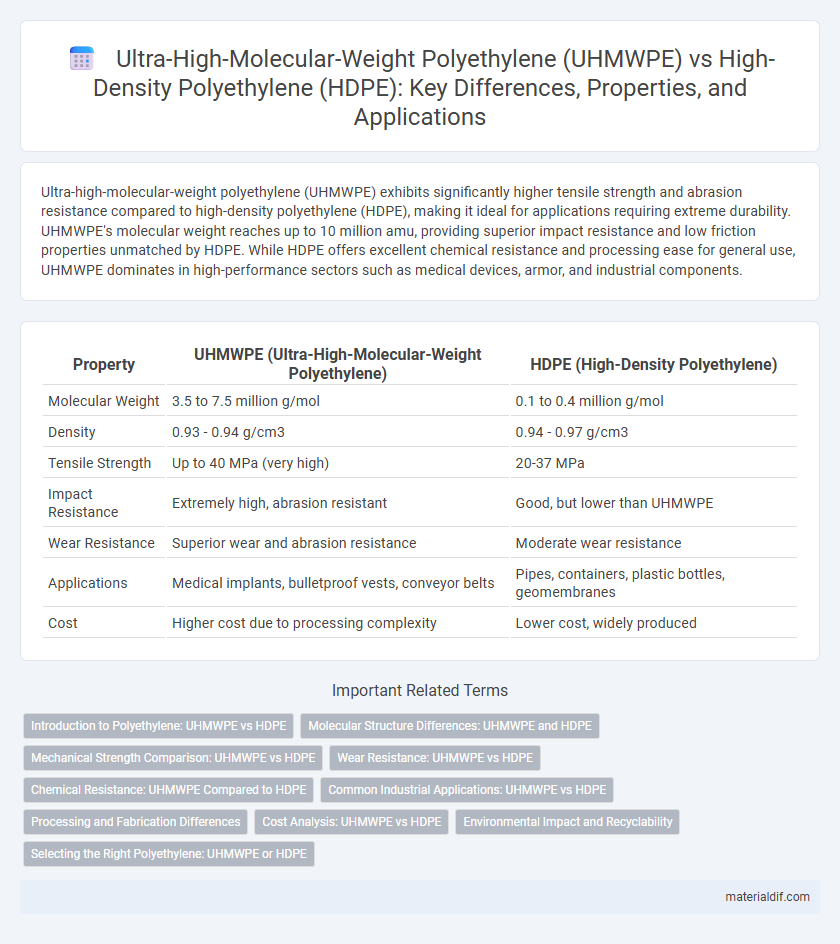

Ultra-high-molecular-weight polyethylene (UHMWPE) exhibits significantly higher tensile strength and abrasion resistance compared to high-density polyethylene (HDPE), making it ideal for applications requiring extreme durability. UHMWPE's molecular weight reaches up to 10 million amu, providing superior impact resistance and low friction properties unmatched by HDPE. While HDPE offers excellent chemical resistance and processing ease for general use, UHMWPE dominates in high-performance sectors such as medical devices, armor, and industrial components.

Table of Comparison

| Property | UHMWPE (Ultra-High-Molecular-Weight Polyethylene) | HDPE (High-Density Polyethylene) |

|---|---|---|

| Molecular Weight | 3.5 to 7.5 million g/mol | 0.1 to 0.4 million g/mol |

| Density | 0.93 - 0.94 g/cm3 | 0.94 - 0.97 g/cm3 |

| Tensile Strength | Up to 40 MPa (very high) | 20-37 MPa |

| Impact Resistance | Extremely high, abrasion resistant | Good, but lower than UHMWPE |

| Wear Resistance | Superior wear and abrasion resistance | Moderate wear resistance |

| Applications | Medical implants, bulletproof vests, conveyor belts | Pipes, containers, plastic bottles, geomembranes |

| Cost | Higher cost due to processing complexity | Lower cost, widely produced |

Introduction to Polyethylene: UHMWPE vs HDPE

Ultra-high-molecular-weight polyethylene (UHMWPE) features exceptionally long molecular chains, resulting in superior abrasion resistance, high tensile strength, and excellent impact performance compared to high-density polyethylene (HDPE). HDPE exhibits a more crystalline structure and higher density, providing robust chemical resistance, rigidity, and ease of processing for applications like piping and containers. Both UHMWPE and HDPE serve critical roles in industrial and medical fields, with UHMWPE favored for durability and wear resistance and HDPE for versatile structural uses.

Molecular Structure Differences: UHMWPE and HDPE

Ultra-high-molecular-weight polyethylene (UHMWPE) features significantly longer polymer chains compared to high-density polyethylene (HDPE), resulting in higher molecular weight and enhanced tensile strength. UHMWPE exhibits an extended chain entanglement and molecular alignment that contributes to superior abrasion resistance and impact strength. In contrast, HDPE has shorter polymer chains with a highly crystalline structure, providing rigidity and chemical resistance but lower toughness than UHMWPE.

Mechanical Strength Comparison: UHMWPE vs HDPE

Ultra-high-molecular-weight polyethylene (UHMWPE) exhibits significantly higher mechanical strength compared to high-density polyethylene (HDPE), with tensile strength values reaching up to 40 MPa for UHMWPE versus 20-30 MPa typical for HDPE. The ultra-long polymer chains in UHMWPE provide exceptional abrasion resistance and impact toughness, making it ideal for demanding applications such as medical implants and ballistic protection. HDPE, while offering good strength and rigidity, lacks the extreme durability and wear resistance found in UHMWPE, limiting its use to less strenuous environments.

Wear Resistance: UHMWPE vs HDPE

Ultra-high-molecular-weight polyethylene (UHMWPE) exhibits significantly superior wear resistance compared to high-density polyethylene (HDPE) due to its extremely long polymer chains and high molecular weight, which enhance its durability and abrasion resistance. UHMWPE is commonly used in applications requiring exceptional wear performance, such as medical implants, conveyor belts, and protective gear, whereas HDPE is favored for general-purpose containers and piping. The enhanced wear resistance of UHMWPE results in a longer service life and reduced maintenance in demanding environments.

Chemical Resistance: UHMWPE Compared to HDPE

Ultra-high-molecular-weight polyethylene (UHMWPE) exhibits superior chemical resistance compared to high-density polyethylene (HDPE), particularly against aggressive chemicals such as strong acids, alkalis, and solvents. The higher molecular weight and densely packed polymer chains in UHMWPE result in lower permeability and enhanced resistance to chemical degradation. This makes UHMWPE ideal for applications requiring prolonged exposure to harsh chemical environments where HDPE may experience swelling or structural compromise.

Common Industrial Applications: UHMWPE vs HDPE

Ultra-high-molecular-weight polyethylene (UHMWPE) is extensively used in industrial applications requiring exceptional wear resistance and high impact strength, such as conveyor belts, medical devices, and bulletproof vests. High-density polyethylene (HDPE) is commonly employed in packaging, piping, and plastic containers due to its chemical resistance and structural rigidity. The superior abrasion resistance of UHMWPE makes it ideal for heavy-duty mechanical parts, while HDPE's cost-effectiveness suits large-scale production in less demanding environments.

Processing and Fabrication Differences

Ultra-high-molecular-weight polyethylene (UHMWPE) requires specialized processing techniques such as compression molding and ram extrusion due to its extremely long polymer chains and high viscosity, which make it difficult to process using conventional methods. High-density polyethylene (HDPE) benefits from more versatile fabrication options including injection molding, blow molding, and extrusion, as its lower molecular weight allows easier flow and melting. The thermal stability and shear sensitivity of UHMWPE necessitate slower processing speeds and higher temperatures compared to HDPE, impacting manufacturing efficiency and tooling requirements.

Cost Analysis: UHMWPE vs HDPE

Ultra-high-molecular-weight polyethylene (UHMWPE) typically incurs higher production and raw material costs compared to high-density polyethylene (HDPE) due to its longer polymer chains and specialized manufacturing processes. HDPE offers a cost-effective solution for applications requiring moderate strength and chemical resistance, benefiting from widespread availability and established production methods. The significant price difference influences material selection, with UHMWPE reserved for high-performance applications demanding superior abrasion resistance and impact strength despite its premium cost.

Environmental Impact and Recyclability

Ultra-high-molecular-weight polyethylene (UHMWPE) exhibits greater durability and chemical resistance compared to high-density polyethylene (HDPE), resulting in longer product lifespans that reduce environmental waste. HDPE is more widely recyclable through established municipal recycling programs, whereas UHMWPE recycling is limited due to its higher molecular weight and specialized processing requirements. Both polymers are derived from fossil fuels, but HDPE's better recyclability contributes to a lower overall environmental impact in circular economy practices.

Selecting the Right Polyethylene: UHMWPE or HDPE

Ultra-high-molecular-weight polyethylene (UHMWPE) offers exceptional impact resistance, wear properties, and chemical inertness, making it ideal for demanding industrial applications such as medical implants and ballistic protection. High-density polyethylene (HDPE) provides excellent tensile strength, environmental stress crack resistance, and affordability, making it suitable for packaging, containers, and piping systems. Selecting between UHMWPE and HDPE depends on the performance requirements, with UHMWPE favored for high-stress, high-wear uses and HDPE for cost-effective, general-purpose applications.

Ultra-high-molecular-weight polyethylene (UHMWPE) vs High-density polyethylene (HDPE) Infographic

materialdif.com

materialdif.com