Linear Low-Density Polyethylene (LLDPE) offers superior tensile strength and puncture resistance compared to Low-Density Polyethylene (LDPE), making it ideal for flexible packaging applications. LLDPE's molecular structure provides better stretchability and environmental stress crack resistance, enhancing durability in products subject to heavy use. LDPE, while more transparent and easier to process, generally exhibits lower mechanical strength and stiffness than LLDPE, limiting its use to lighter duty packaging and films.

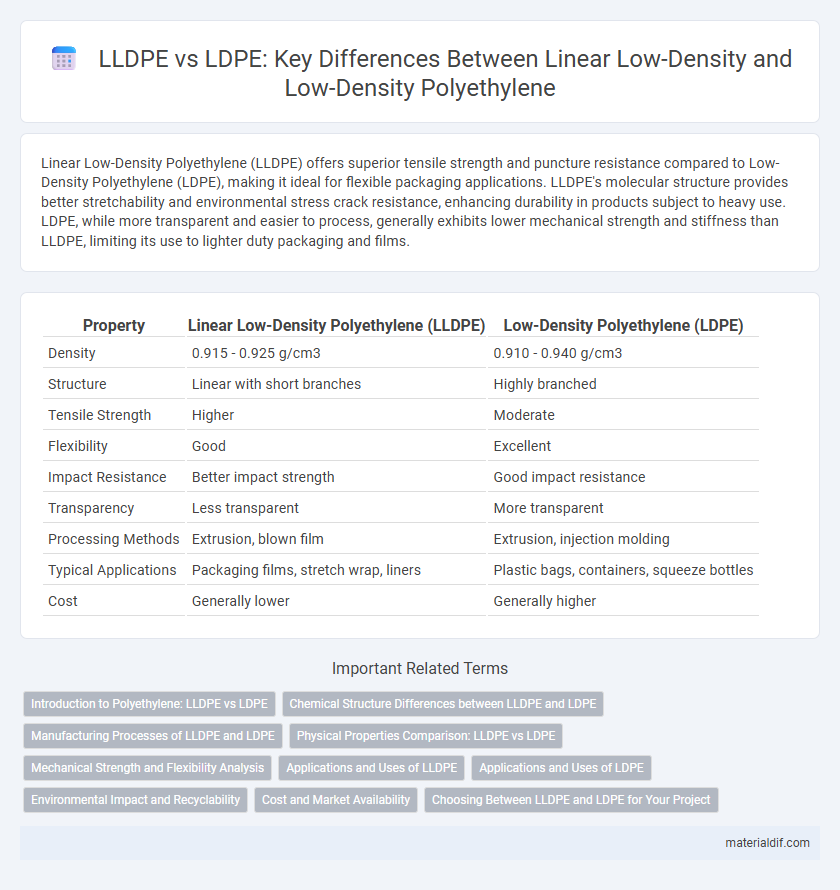

Table of Comparison

| Property | Linear Low-Density Polyethylene (LLDPE) | Low-Density Polyethylene (LDPE) |

|---|---|---|

| Density | 0.915 - 0.925 g/cm3 | 0.910 - 0.940 g/cm3 |

| Structure | Linear with short branches | Highly branched |

| Tensile Strength | Higher | Moderate |

| Flexibility | Good | Excellent |

| Impact Resistance | Better impact strength | Good impact resistance |

| Transparency | Less transparent | More transparent |

| Processing Methods | Extrusion, blown film | Extrusion, injection molding |

| Typical Applications | Packaging films, stretch wrap, liners | Plastic bags, containers, squeeze bottles |

| Cost | Generally lower | Generally higher |

Introduction to Polyethylene: LLDPE vs LDPE

Linear Low-Density Polyethylene (LLDPE) features a linear polymer backbone with significant short-chain branching, resulting in higher tensile strength and impact resistance compared to Low-Density Polyethylene (LDPE), which has a highly branched structure. LLDPE typically exhibits superior tensile strength and puncture resistance, making it ideal for stretch films and flexible packaging, whereas LDPE is favored for its clarity, flexibility, and ease of processing in applications such as grocery bags and plastic films. The microstructural differences in branching between LLDPE and LDPE directly influence their mechanical properties and manufacturing versatility.

Chemical Structure Differences between LLDPE and LDPE

Linear Low-Density Polyethylene (LLDPE) features a linear backbone with significant short-chain branching introduced during copolymerization, resulting in a more uniform molecular structure compared to Low-Density Polyethylene (LDPE). LDPE exhibits a highly branched chemical structure with long and short chain branches formed during high-pressure free radical polymerization, causing a less dense molecular packing. These structural differences influence the mechanical properties, crystallinity, and density, making LLDPE stronger and more flexible, while LDPE offers higher clarity and toughness.

Manufacturing Processes of LLDPE and LDPE

Linear Low-Density Polyethylene (LLDPE) is produced through copolymerization of ethylene with alpha-olefins using solution or gas-phase polymerization processes facilitated by Ziegler-Natta or metallocene catalysts, resulting in a linear polymer structure with short-chain branching. Low-Density Polyethylene (LDPE) is manufactured via high-pressure free-radical polymerization of ethylene in autoclave or tubular reactors, leading to a highly branched polymer with a less dense structure. The distinct polymerization methods impart different molecular architectures that influence mechanical properties and applications of LLDPE and LDPE.

Physical Properties Comparison: LLDPE vs LDPE

Linear Low-Density Polyethylene (LLDPE) exhibits higher tensile strength and greater puncture resistance compared to Low-Density Polyethylene (LDPE) due to its linear polymer chains with short branching. LDPE features a lower density and higher flexibility, resulting from its highly branched molecular structure that provides enhanced clarity and softness. The distinct crystallinity and molecular arrangement influence LLDPE's superior impact strength and LDPE's better stress crack resistance in packaging applications.

Mechanical Strength and Flexibility Analysis

Linear Low-Density Polyethylene (LLDPE) exhibits superior mechanical strength compared to Low-Density Polyethylene (LDPE) due to its linear molecular structure with short, uniform branches that enhance tensile strength and puncture resistance. LDPE, characterized by its highly branched polymer chains, offers greater flexibility and elongation at break, making it ideal for applications requiring softness and stretchability. The trade-off between LLDPE's enhanced durability and LDPE's increased flexibility determines their suitability for specific uses such as packaging films and flexible containers.

Applications and Uses of LLDPE

Linear Low-Density Polyethylene (LLDPE) is extensively used in flexible packaging, including stretch films, garbage bags, and agricultural films, due to its superior tensile strength and puncture resistance compared to Low-Density Polyethylene (LDPE). LLDPE's enhanced shear strength and chemical resistance make it ideal for industrial liners, coatings, and injection molding applications. The material's adaptability also supports its use in toys, wire insulation, and molded containers, where durability and flexibility are crucial.

Applications and Uses of LDPE

Low-Density Polyethylene (LDPE) is widely used in packaging applications such as plastic bags, film wrap, and containers due to its flexibility, transparency, and resistance to moisture. It is preferred in food packaging, squeeze bottles, and corrosion-resistant coatings because of its excellent clarity and low cost. LDPE's applications extend to wire and cable insulation, as well as producing molded laboratory equipment and plastic tubing, benefiting from its toughness and chemical resistance.

Environmental Impact and Recyclability

Linear Low-Density Polyethylene (LLDPE) demonstrates higher recyclability compared to Low-Density Polyethylene (LDPE) due to its more uniform molecular structure, which facilitates mechanical recycling processes. LLDPE's lower environmental impact is attributed to its efficient production methods and reduced greenhouse gas emissions during manufacturing. LDPE, while versatile and widely used, presents challenges in recycling pipelines because of its branched molecular chains, leading to lower recycling rates and increased environmental burden.

Cost and Market Availability

Linear Low-Density Polyethylene (LLDPE) generally offers a lower cost per unit compared to Low-Density Polyethylene (LDPE) due to more efficient production processes and higher raw material utilization. Market availability of LLDPE is broader, driven by its widespread application in packaging films, agricultural coverings, and stretch wraps, making it more competitive globally. LDPE remains available but tends to have higher production costs and limited supply relative to LLDPE, impacting its market price and distribution.

Choosing Between LLDPE and LDPE for Your Project

Choosing between Linear Low-Density Polyethylene (LLDPE) and Low-Density Polyethylene (LDPE) depends on the specific requirements of your project, such as flexibility, tensile strength, and environmental stress crack resistance. LLDPE offers higher tensile strength and better puncture resistance, making it ideal for applications like stretch films, flexible tubing, and packaging requiring durability. LDPE, with its greater clarity and more pliable texture, is preferred for applications requiring softer touch and transparency, such as plastic bags, trays, and containers.

Linear Low-Density Polyethylene (LLDPE) vs Low-Density Polyethylene (LDPE) Infographic

materialdif.com

materialdif.com