Cross-linked polyethylene (PEX) exhibits superior thermal resistance, chemical stability, and mechanical strength compared to non-cross-linked polyethylene, making it ideal for plumbing and radiant heating systems. Non-cross-linked polyethylene, while more flexible and easier to process, lacks the durability and temperature tolerance of PEX, limiting its use in high-stress applications. The cross-linking process enhances polymer chain bonding, resulting in improved resistance to cracking, deformation, and environmental stress.

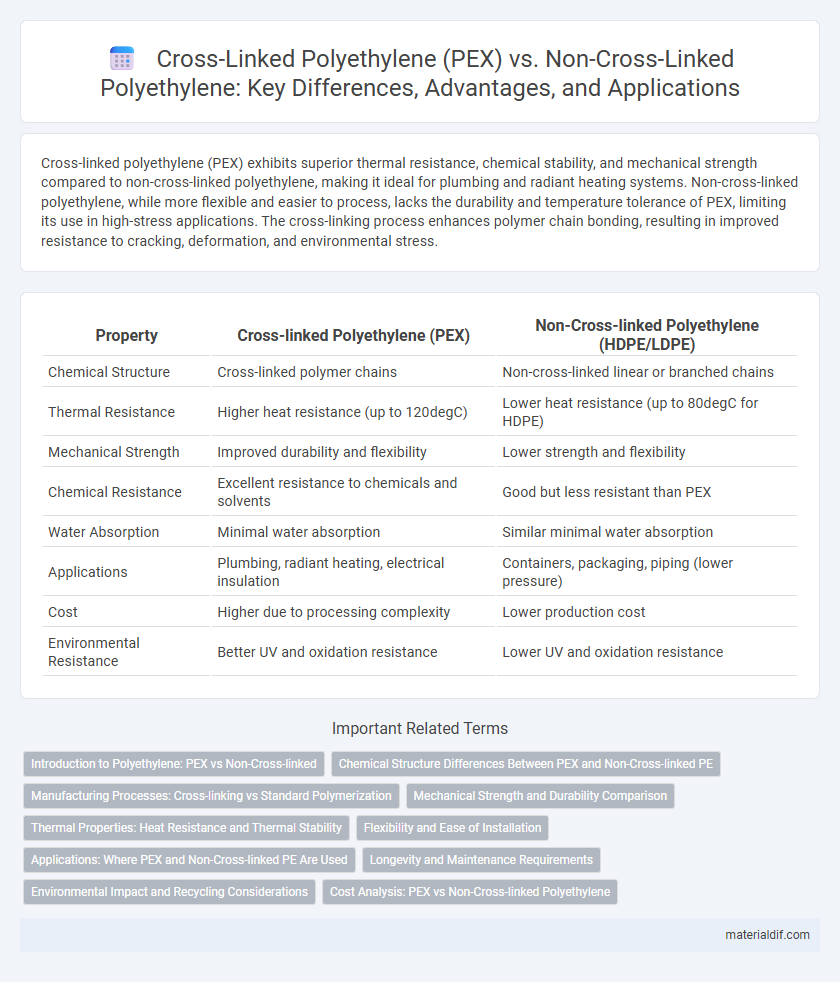

Table of Comparison

| Property | Cross-linked Polyethylene (PEX) | Non-Cross-linked Polyethylene (HDPE/LDPE) |

|---|---|---|

| Chemical Structure | Cross-linked polymer chains | Non-cross-linked linear or branched chains |

| Thermal Resistance | Higher heat resistance (up to 120degC) | Lower heat resistance (up to 80degC for HDPE) |

| Mechanical Strength | Improved durability and flexibility | Lower strength and flexibility |

| Chemical Resistance | Excellent resistance to chemicals and solvents | Good but less resistant than PEX |

| Water Absorption | Minimal water absorption | Similar minimal water absorption |

| Applications | Plumbing, radiant heating, electrical insulation | Containers, packaging, piping (lower pressure) |

| Cost | Higher due to processing complexity | Lower production cost |

| Environmental Resistance | Better UV and oxidation resistance | Lower UV and oxidation resistance |

Introduction to Polyethylene: PEX vs Non-Cross-linked

Cross-linked polyethylene (PEX) differs from non-cross-linked polyethylene by its enhanced molecular structure, formed through cross-linking that improves thermal resistance and mechanical strength. PEX is widely used in plumbing and heating applications due to its superior flexibility and durability, while non-cross-linked polyethylene remains common in packaging and insulation because of its lower cost and ease of processing. The structural modification in PEX results in better chemical resistance and longevity compared to non-cross-linked variants.

Chemical Structure Differences Between PEX and Non-Cross-linked PE

Cross-linked polyethylene (PEX) features a three-dimensional network of covalent bonds formed between polymer chains, enhancing thermal stability and mechanical strength compared to non-cross-linked polyethylene, which consists of individual, linear or branched chains without such interconnections. This cross-linking process alters the chemical structure by creating covalent bridges between polymer chains, reducing chain mobility and increasing resistance to deformation under heat and stress. Non-cross-linked polyethylene retains a thermoplastic behavior, allowing it to melt and flow upon heating, whereas PEX behaves as a thermoset, maintaining its shape due to the permanent chemical cross-links.

Manufacturing Processes: Cross-linking vs Standard Polymerization

Cross-linked polyethylene (PEX) undergoes a specialized cross-linking process, such as peroxide, silane, or electron beam methods, which chemically bonds polymer chains to enhance thermal and mechanical properties. In contrast, non-cross-linked polyethylene is produced through standard polymerization techniques like high-pressure radical polymerization or Ziegler-Natta catalysis, resulting in linear polymer chains with lower heat resistance and mechanical strength. The manufacturing differences significantly impact material performance, with PEX exhibiting superior chemical resistance, dimensional stability, and durability compared to conventional polyethylene.

Mechanical Strength and Durability Comparison

Cross-linked polyethylene (PEX) exhibits significantly higher mechanical strength and enhanced durability compared to non-cross-linked polyethylene due to its networked polymer structure, which improves resistance to stress cracking and thermal deformation. Non-cross-linked polyethylene tends to have lower tensile strength and reduced resistance to environmental factors, resulting in quicker degradation under harsh conditions. The superior performance of PEX makes it ideal for applications requiring long-term reliability and robustness, such as plumbing and radiant heating systems.

Thermal Properties: Heat Resistance and Thermal Stability

Cross-linked Polyethylene (PEX) exhibits superior heat resistance and thermal stability compared to non-cross-linked polyethylene due to its networked molecular structure, which enhances its ability to withstand higher temperatures without deformation. PEX maintains mechanical integrity at temperatures up to 120degC and resists thermal oxidation, making it ideal for applications such as hot water piping and radiant heating systems. In contrast, non-cross-linked polyethylene typically degrades or softens at lower temperatures around 80degC, limiting its use in high-temperature environments.

Flexibility and Ease of Installation

Cross-linked polyethylene (PEX) exhibits superior flexibility compared to non-cross-linked polyethylene due to its enhanced molecular structure, allowing it to bend without kinking, which significantly simplifies installation in tight spaces. Non-cross-linked polyethylene tends to be stiffer and less resilient under stress, making it more challenging to handle and install, especially in complex plumbing or radiant heating systems. The improved flexibility and durability of PEX reduce labor time and material waste, making it the preferred choice for modern piping applications.

Applications: Where PEX and Non-Cross-linked PE Are Used

Cross-linked polyethylene (PEX) is widely used in plumbing, radiant floor heating, and industrial tubing due to its enhanced thermal resistance and flexibility. Non-cross-linked polyethylene (PE) commonly appears in packaging films, plastic containers, and everyday consumer goods because of its lightweight and cost-effective properties. The choice between PEX and non-cross-linked PE depends on application-specific requirements such as temperature tolerance, mechanical strength, and chemical resistance.

Longevity and Maintenance Requirements

Cross-linked Polyethylene (PEX) exhibits superior longevity compared to non-cross-linked polyethylene due to its enhanced molecular structure, which provides increased resistance to heat, chemicals, and mechanical stress. PEX requires minimal maintenance as it resists cracking, scaling, and corrosion, extending its service life in plumbing and heating applications. Non-cross-linked polyethylene typically demands more frequent inspection and replacement due to its lower thermal stability and susceptibility to environmental degradation.

Environmental Impact and Recycling Considerations

Cross-linked polyethylene (PEX) exhibits superior chemical and thermal resistance but poses significant recycling challenges due to its thermoset nature, which prevents remelting and reprocessing. Non-cross-linked polyethylene, such as HDPE and LDPE, can be more easily recycled through mechanical processes, resulting in lower environmental impact and higher circular economy potential. The environmental footprint of PEX is amplified by limited recycling options, often leading to landfill disposal or incineration, whereas non-cross-linked variants benefit from established recycling streams and reduced waste generation.

Cost Analysis: PEX vs Non-Cross-linked Polyethylene

Cross-linked polyethylene (PEX) typically involves higher initial material and manufacturing costs due to its complex cross-linking process, resulting in enhanced thermal and mechanical properties. Non-cross-linked polyethylene (PE) offers lower upfront expenses but often requires more frequent replacement and maintenance over time, impacting total lifecycle costs. Cost analysis must weigh PEX's durability and performance benefits against the affordability and ease of processing of non-cross-linked polyethylene for specific applications.

Cross-linked Polyethylene (PEX) vs Non-Cross-linked Polyethylene Infographic

materialdif.com

materialdif.com