Cross-linked Polyethylene (PEX) offers enhanced thermal resistance, flexibility, and chemical stability compared to virgin polyethylene, making it ideal for plumbing, heating, and insulation applications. Virgin polyethylene provides a more straightforward, cost-effective solution with excellent clarity and processability but lacks the durability and heat tolerance of PEX. The choice depends on specific application requirements such as temperature endurance and mechanical stress.

Table of Comparison

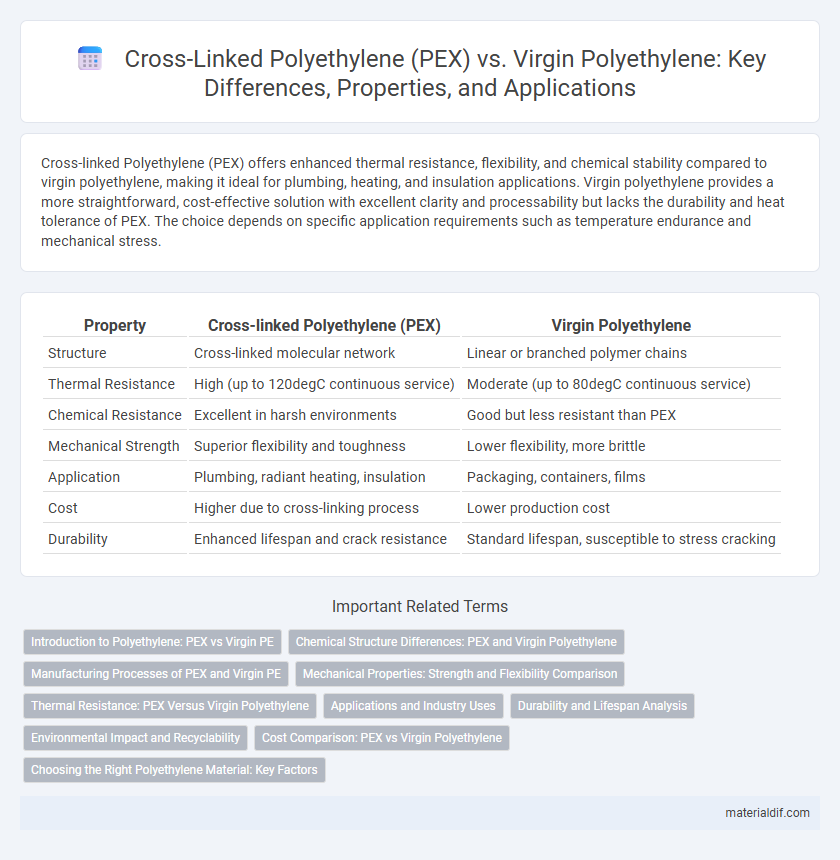

| Property | Cross-linked Polyethylene (PEX) | Virgin Polyethylene |

|---|---|---|

| Structure | Cross-linked molecular network | Linear or branched polymer chains |

| Thermal Resistance | High (up to 120degC continuous service) | Moderate (up to 80degC continuous service) |

| Chemical Resistance | Excellent in harsh environments | Good but less resistant than PEX |

| Mechanical Strength | Superior flexibility and toughness | Lower flexibility, more brittle |

| Application | Plumbing, radiant heating, insulation | Packaging, containers, films |

| Cost | Higher due to cross-linking process | Lower production cost |

| Durability | Enhanced lifespan and crack resistance | Standard lifespan, susceptible to stress cracking |

Introduction to Polyethylene: PEX vs Virgin PE

Cross-linked polyethylene (PEX) offers enhanced thermal stability and chemical resistance compared to virgin polyethylene, making it ideal for high-performance applications such as plumbing and radiant heating systems. Virgin polyethylene, characterized by its pure, unmodified polymer chains, provides excellent processability and clarity, commonly used in packaging and films. Understanding the distinctions between PEX and virgin PE is crucial for selecting the right material based on mechanical strength, durability, and environmental exposure.

Chemical Structure Differences: PEX and Virgin Polyethylene

Cross-linked polyethylene (PEX) differs from virgin polyethylene primarily in its chemical structure, where PEX undergoes a cross-linking process that forms covalent bonds between polymer chains, enhancing its thermal and mechanical properties. Virgin polyethylene consists of linear or branched polymer chains without cross-links, resulting in lower resistance to heat and stress. The cross-linking in PEX creates a three-dimensional network that improves durability, elasticity, and chemical resistance compared to the non-cross-linked structure of virgin polyethylene.

Manufacturing Processes of PEX and Virgin PE

Cross-linked polyethylene (PEX) is produced through a chemical or physical cross-linking process that alters the molecular structure of virgin polyethylene, enhancing its thermal and mechanical properties. Virgin polyethylene, typically high-density (HDPE) or low-density (LDPE), is manufactured via polymerization of ethylene using methods such as gas-phase, solution, or slurry polymerization without subsequent molecular modification. The cross-linking in PEX involves methods like peroxide cross-linking, radiation cross-linking, or silane cross-linking, which create covalent bonds between polymer chains, imparting improved resistance to heat, chemical degradation, and stress cracking compared to virgin polyethylene.

Mechanical Properties: Strength and Flexibility Comparison

Cross-linked polyethylene (PEX) exhibits superior mechanical strength and enhanced flexibility compared to virgin polyethylene due to its networked polymer structure, which improves resistance to stress and deformation. Virgin polyethylene, while easier to process, typically has lower tensile strength and reduced elasticity, making it less suitable for high-pressure and temperature applications. The cross-linking in PEX increases impact resistance and thermal stability, optimizing its performance in demanding environments such as plumbing and electrical insulation.

Thermal Resistance: PEX Versus Virgin Polyethylene

Cross-linked polyethylene (PEX) exhibits superior thermal resistance compared to virgin polyethylene due to its enhanced molecular network structure, allowing it to withstand higher temperatures without deforming. PEX maintains stability at temperatures up to 120-160degC, whereas virgin polyethylene typically softens around 80-100degC, limiting its use in high-temperature applications. This thermal endurance makes PEX ideal for plumbing and radiant heating systems where consistent exposure to elevated temperatures is critical.

Applications and Industry Uses

Cross-linked polyethylene (PEX) offers enhanced thermal stability and chemical resistance, making it ideal for plumbing, radiant heating, and industrial piping applications where durability under high temperatures is critical. Virgin polyethylene, with its high purity and flexibility, finds extensive use in packaging, film production, and container manufacturing, benefiting from excellent processability and impact resistance. Industries such as construction and automotive prefer PEX for long-lasting, heat-resistant tubing, while virgin polyethylene dominates consumer goods and food packaging sectors due to its safety and versatility.

Durability and Lifespan Analysis

Cross-linked polyethylene (PEX) exhibits superior durability compared to virgin polyethylene due to its enhanced chemical and thermal resistance, which significantly extends its lifespan in high-stress applications. PEX's cross-linking process creates a three-dimensional network that improves impact strength and reduces environmental stress cracking, resulting in a lifespan of up to 50 years in plumbing and insulation uses. In contrast, virgin polyethylene typically offers a shorter lifespan of 10 to 20 years under similar conditions, as it lacks the molecular stability provided by cross-linking.

Environmental Impact and Recyclability

Cross-linked polyethylene (PEX) has a more complex polymer structure, making it less recyclable compared to virgin polyethylene, which can be easily reprocessed and reused in various applications. Virgin polyethylene typically has a lower environmental impact due to its straightforward recycling pathways, whereas PEX often ends up in landfills because chemical cross-linking hinders melting and reshaping processes. The increased durability and longevity of PEX can reduce the frequency of replacement, partially offsetting its recyclability challenges from an environmental perspective.

Cost Comparison: PEX vs Virgin Polyethylene

Cross-linked polyethylene (PEX) typically incurs higher production costs due to its complex cross-linking process, resulting in increased material expenses compared to virgin polyethylene. Virgin polyethylene, produced through polymerization without modifications, remains more cost-effective for applications where enhanced thermal and chemical resistance are not critical. The cost differential influences selection in industries like plumbing and electrical insulation, where PEX's durability justifies the premium over conventional virgin polyethylene.

Choosing the Right Polyethylene Material: Key Factors

Cross-linked polyethylene (PEX) offers superior chemical resistance, thermal stability up to 200degC, and enhanced mechanical strength compared to virgin polyethylene, making it ideal for demanding applications like plumbing and insulation. Virgin polyethylene provides excellent flexibility, clarity, and is easier to process, suitable for packaging and general-purpose items. Selecting the right polyethylene depends on factors such as temperature requirements, mechanical performance, chemical exposure, and cost-effectiveness for the intended application.

Cross-linked Polyethylene (PEX) vs Virgin Polyethylene Infographic

materialdif.com

materialdif.com