High Molecular Weight Polyethylene (HMWPE) offers enhanced strength and chemical resistance compared to standard polyethylene, making it suitable for industrial applications. Ultra High Molecular Weight Polyethylene (UHMWPE) exceeds HMWPE in molecular weight, delivering superior impact resistance, abrasion durability, and wear properties ideal for demanding environments. The choice between HMWPE and UHMWPE depends on specific performance requirements, balancing cost and mechanical properties for optimal usage.

Table of Comparison

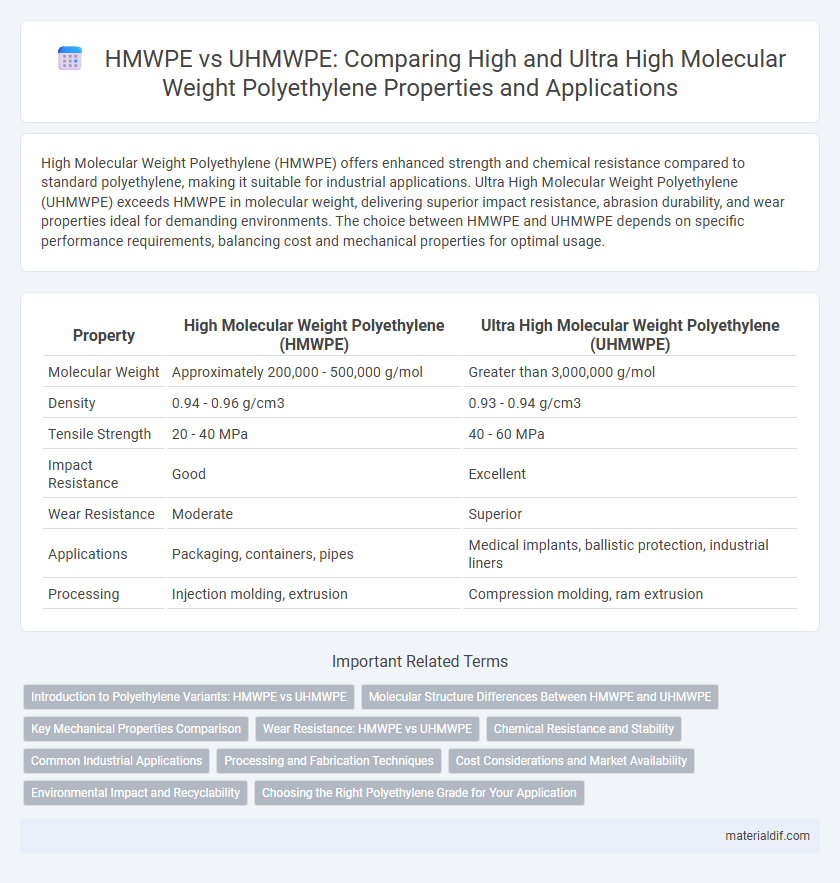

| Property | High Molecular Weight Polyethylene (HMWPE) | Ultra High Molecular Weight Polyethylene (UHMWPE) |

|---|---|---|

| Molecular Weight | Approximately 200,000 - 500,000 g/mol | Greater than 3,000,000 g/mol |

| Density | 0.94 - 0.96 g/cm3 | 0.93 - 0.94 g/cm3 |

| Tensile Strength | 20 - 40 MPa | 40 - 60 MPa |

| Impact Resistance | Good | Excellent |

| Wear Resistance | Moderate | Superior |

| Applications | Packaging, containers, pipes | Medical implants, ballistic protection, industrial liners |

| Processing | Injection molding, extrusion | Compression molding, ram extrusion |

Introduction to Polyethylene Variants: HMWPE vs UHMWPE

High Molecular Weight Polyethylene (HMWPE) and Ultra High Molecular Weight Polyethylene (UHMWPE) are both crucial variants of polyethylene distinguished by their molecular chain lengths, impacting their mechanical properties. HMWPE generally exhibits a molecular weight ranging from 100,000 to 500,000 g/mol, offering improved strength and chemical resistance compared to standard polyethylene. UHMWPE surpasses this with molecular weights typically above 1,000,000 g/mol, resulting in exceptional abrasion resistance, impact strength, and wear performance ideal for demanding industrial and biomedical applications.

Molecular Structure Differences Between HMWPE and UHMWPE

High Molecular Weight Polyethylene (HMWPE) features polymer chains with molecular weights typically ranging from 300,000 to 800,000 g/mol, resulting in moderate chain length and entanglement. Ultra High Molecular Weight Polyethylene (UHMWPE) possesses significantly longer polymer chains, with molecular weights exceeding 3 million g/mol, enhancing intermolecular interactions and mechanical strength. The extended molecular structure of UHMWPE leads to higher tensile strength, impact resistance, and abrasion resistance compared to HMWPE.

Key Mechanical Properties Comparison

Ultra High Molecular Weight Polyethylene (UHMWPE) exhibits significantly higher tensile strength and impact resistance compared to High Molecular Weight Polyethylene (HMWPE), owing to its longer polymer chains and greater molecular weight. UHMWPE also demonstrates superior wear resistance and lower coefficient of friction, making it ideal for applications requiring extreme durability and low abrasion. In contrast, HMWPE offers better processability and stiffness but falls short in mechanical performance metrics crucial for high-stress environments.

Wear Resistance: HMWPE vs UHMWPE

High Molecular Weight Polyethylene (HMWPE) offers enhanced wear resistance compared to standard polyethylene grades, making it suitable for applications involving moderate abrasion. Ultra High Molecular Weight Polyethylene (UHMWPE), with molecular weights typically between 3.1 and 5.67 million g/mol, exhibits superior wear resistance due to its extremely long polymer chains and high crystallinity, enabling exceptional durability in highly abrasive environments. UHMWPE's superior wear performance makes it the preferred material for demanding industrial uses such as conveyor belts, medical implants, and impact-resistant components.

Chemical Resistance and Stability

High Molecular Weight Polyethylene (HMWPE) exhibits excellent chemical resistance against a wide range of solvents, acids, and bases, making it suitable for many industrial applications. Ultra High Molecular Weight Polyethylene (UHMWPE) surpasses HMWPE in chemical stability due to its higher molecular weight, resulting in superior abrasion resistance and impact strength under harsh chemical environments. Both materials demonstrate outstanding durability, but UHMWPE provides enhanced performance in extreme conditions such as strong oxidizers and aggressive solvents.

Common Industrial Applications

High Molecular Weight Polyethylene (HMWPE) is commonly used in applications requiring moderate wear resistance and chemical stability, such as packaging films, geomembranes, and containers. Ultra High Molecular Weight Polyethylene (UHMWPE) offers superior impact strength and abrasion resistance, making it ideal for industrial parts like conveyor belts, liners, and orthopedic implants. Both materials excel in environments demanding durability and low friction but differ in molecular weight, influencing their performance and application scope.

Processing and Fabrication Techniques

High Molecular Weight Polyethylene (HMWPE) is typically processed using conventional methods such as injection molding and extrusion, benefiting from moderate molecular weights that provide good melt flow characteristics. Ultra High Molecular Weight Polyethylene (UHMWPE) requires specialized processing techniques like compression molding and ram extrusion due to its extremely high molecular weight, which results in high melt viscosity and poor flowability. Fabrication of UHMWPE often involves techniques such as gel spinning for fiber production, enabling enhanced mechanical properties compared to HMWPE products manufactured via standard thermoplastic processing.

Cost Considerations and Market Availability

High Molecular Weight Polyethylene (HMWPE) generally offers a balance of mechanical properties with lower production costs compared to Ultra High Molecular Weight Polyethylene (UHMWPE), which features superior wear resistance and tensile strength but at a higher price point. Market availability of UHMWPE is more specialized, often sourced for high-performance applications such as medical implants and ballistic protection, whereas HMWPE is widely accessible for general industrial uses like packaging and piping. Cost considerations drive manufacturers to choose HMWPE for cost-sensitive projects, while UHMWPE is preferred when durability and performance justify the premium expense.

Environmental Impact and Recyclability

High Molecular Weight Polyethylene (HMWPE) and Ultra High Molecular Weight Polyethylene (UHMWPE) differ significantly in environmental impact and recyclability due to their molecular structure and density. UHMWPE exhibits enhanced durability and wear resistance, leading to longer product lifespans and reduced waste generation compared to HMWPE, but its extremely high molecular weight complicates mechanical recycling processes. Both materials are thermoplastics and recyclable; however, HMWPE offers more straightforward recycling routes with higher efficiency, while UHMWPE often requires specialized treatments or downcycling, impacting its overall environmental footprint.

Choosing the Right Polyethylene Grade for Your Application

High Molecular Weight Polyethylene (HMWPE) offers excellent abrasion resistance and impact strength suitable for load-bearing applications, while Ultra High Molecular Weight Polyethylene (UHMWPE) provides superior wear resistance and ultra-low friction for high-performance uses like medical implants and industrial liners. Selecting the right polyethylene grade depends on the required balance of mechanical properties, chemical resistance, and operational environment. Evaluating factors such as tensile strength, molecular weight distribution, and surface hardness ensures optimal performance and longevity in specialized applications.

High Molecular Weight Polyethylene (HMWPE) vs Ultra High Molecular Weight Polyethylene (UHMWPE) Infographic

materialdif.com

materialdif.com