Bimodal polyethylene (PE) offers a unique molecular structure with two distinct molecular weight distributions, enhancing mechanical properties and processability compared to unimodal PE, which has a single molecular weight distribution. This bimodal structure improves strength, toughness, and environmental stress crack resistance, making it ideal for demanding applications like high-performance pipes and films. Unimodal PE, while easier to process and less expensive, generally exhibits lower strength and flexibility, limiting its use in high-stress environments.

Table of Comparison

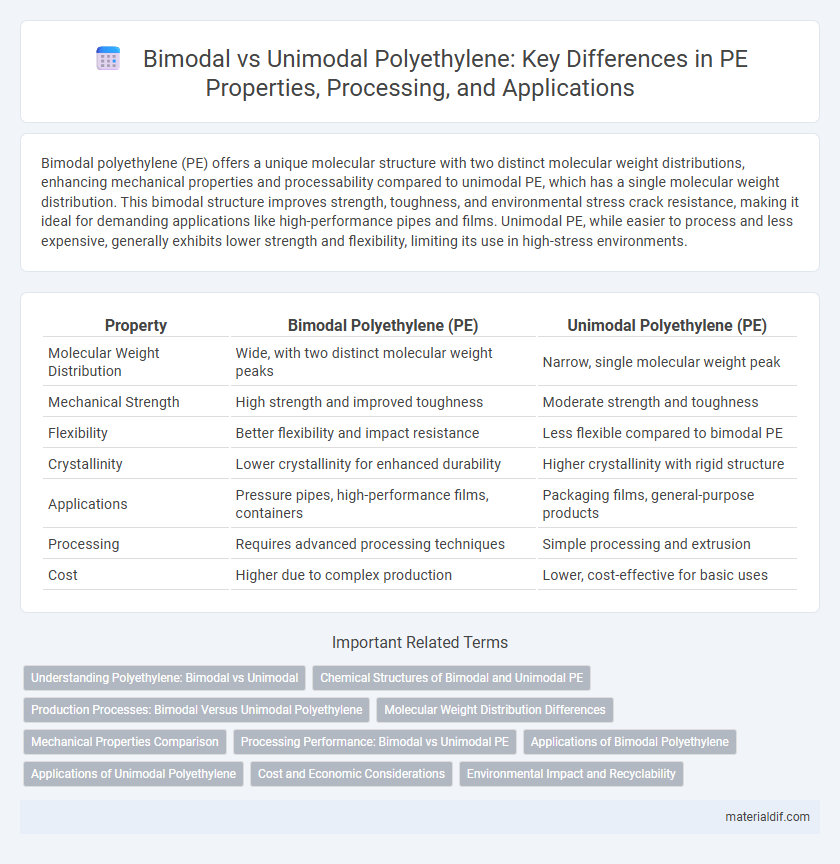

| Property | Bimodal Polyethylene (PE) | Unimodal Polyethylene (PE) |

|---|---|---|

| Molecular Weight Distribution | Wide, with two distinct molecular weight peaks | Narrow, single molecular weight peak |

| Mechanical Strength | High strength and improved toughness | Moderate strength and toughness |

| Flexibility | Better flexibility and impact resistance | Less flexible compared to bimodal PE |

| Crystallinity | Lower crystallinity for enhanced durability | Higher crystallinity with rigid structure |

| Applications | Pressure pipes, high-performance films, containers | Packaging films, general-purpose products |

| Processing | Requires advanced processing techniques | Simple processing and extrusion |

| Cost | Higher due to complex production | Lower, cost-effective for basic uses |

Understanding Polyethylene: Bimodal vs Unimodal

Bimodal polyethylene (PE) features a dual molecular weight distribution that enhances mechanical strength, impact resistance, and processability compared to unimodal PE, which has a single molecular weight distribution. This structural variation allows bimodal PE to achieve superior performance in applications such as high-pressure pipelines and film extrusion. Understanding the differences in molecular architecture between bimodal and unimodal PE is essential for optimizing polymer selection based on specific industrial requirements.

Chemical Structures of Bimodal and Unimodal PE

Bimodal polyethylene features two distinct molecular weight distributions, combining both high and low molecular weight chains, which results in a more complex chemical structure compared to unimodal polyethylene that possesses a single, uniform molecular weight distribution. This dual molecular weight profile in bimodal PE enhances properties like strength and processability by optimizing chain entanglement and crystallinity. Unimodal PE, with its consistent chain length, typically exhibits less mechanical versatility but offers simpler chemical structure and processing behavior.

Production Processes: Bimodal Versus Unimodal Polyethylene

Bimodal polyethylene production involves a dual-reactor system that sequentially synthesizes high and low molecular weight polymer fractions, optimizing mechanical properties and processability. Unimodal polyethylene is produced in a single reactor, yielding a polymer with a uniform molecular weight distribution but typically lower toughness and stiffness. The dual-reactor bimodal process enhances impact resistance and environmental stress crack resistance compared to unimodal PE, making it preferable for demanding applications.

Molecular Weight Distribution Differences

Bimodal polyethylene (PE) exhibits a dual molecular weight distribution, combining low and high molecular weight fractions that enhance processability and mechanical performance. In contrast, unimodal PE has a single molecular weight distribution, typically resulting in a narrower range that limits the balance between strength and flexibility. The broader molecular weight distribution in bimodal PE enables improved impact resistance and tensile properties compared to the uniform structure of unimodal PE.

Mechanical Properties Comparison

Bimodal polyethylene exhibits superior mechanical properties compared to unimodal PE due to its dual molecular weight distribution, enhancing tensile strength, impact resistance, and environmental stress cracking resistance. The high molecular weight fraction in bimodal PE improves toughness, while the low molecular weight fraction facilitates processability, resulting in a balanced combination of stiffness and flexibility. Unimodal PE typically shows lower strength and reduced resistance to deformation under stress, making bimodal PE preferable for demanding industrial applications.

Processing Performance: Bimodal vs Unimodal PE

Bimodal polyethylene exhibits superior processing performance compared to unimodal PE due to its dual molecular weight distribution, which enhances melt strength and flow stability during extrusion and injection molding. This complex structure allows bimodal PE to achieve higher output rates with reduced die swell and improved surface finish. In contrast, unimodal PE typically offers more uniform properties but lower processability, limiting its efficiency in high-demand manufacturing applications.

Applications of Bimodal Polyethylene

Bimodal polyethylene exhibits superior mechanical properties and enhanced processability compared to unimodal PE, making it ideal for high-performance applications such as pressure pipes, geomembranes, and blow molding. Its dual molecular weight distribution provides improved impact resistance, chemical resistance, and toughness, crucial for demanding industrial uses. Bimodal PE's versatility and durability enable its widespread adoption in sectors requiring reliable strength and flexibility under harsh conditions.

Applications of Unimodal Polyethylene

Unimodal polyethylene, characterized by a single molecular weight distribution, finds extensive use in applications requiring uniform mechanical properties such as films, pipes, and injection molding products. Its consistent polymer chain length enhances processability and mechanical strength, making it ideal for packaging materials and containers. The predictable melt flow properties of unimodal PE improve film clarity and sealing efficiency in flexible packaging.

Cost and Economic Considerations

Bimodal polyethylene typically incurs higher production costs due to its complex dual-reactor technology, which blends varying molecular weights for enhanced mechanical properties. Unimodal PE is generally more cost-effective, with simpler manufacturing processes resulting in lower energy consumption and production expenses. Economic considerations favor bimodal PE in applications demanding superior performance, while unimodal PE remains preferable for budget-sensitive projects with less stringent material requirements.

Environmental Impact and Recyclability

Bimodal polyethylene (PE) exhibits enhanced recyclability due to its optimized molecular weight distribution, which allows for better processing and mechanical properties in recycled materials compared to unimodal PE. The environmental impact of bimodal PE is reduced as it enables lower energy consumption during production and facilitates higher-quality recycling loops, thereby contributing to circular economy efforts. Unimodal PE, with its uniform molecular structure, often faces limitations in recyclability and mechanical performance, resulting in higher waste generation and environmental burden.

Bimodal PE vs Unimodal PE Infographic

materialdif.com

materialdif.com