Monomer cast polyethylene PET is produced through a casting process that yields high clarity and excellent dimensional stability, making it ideal for packaging and optical applications. Polymerization grade polyethylene PET, synthesized via polymerization, offers superior molecular weight distribution and enhanced mechanical properties suitable for fiber and film manufacturing. Choosing between monomer cast and polymerization grade depends on the end-use requirements such as clarity, strength, and processing flexibility.

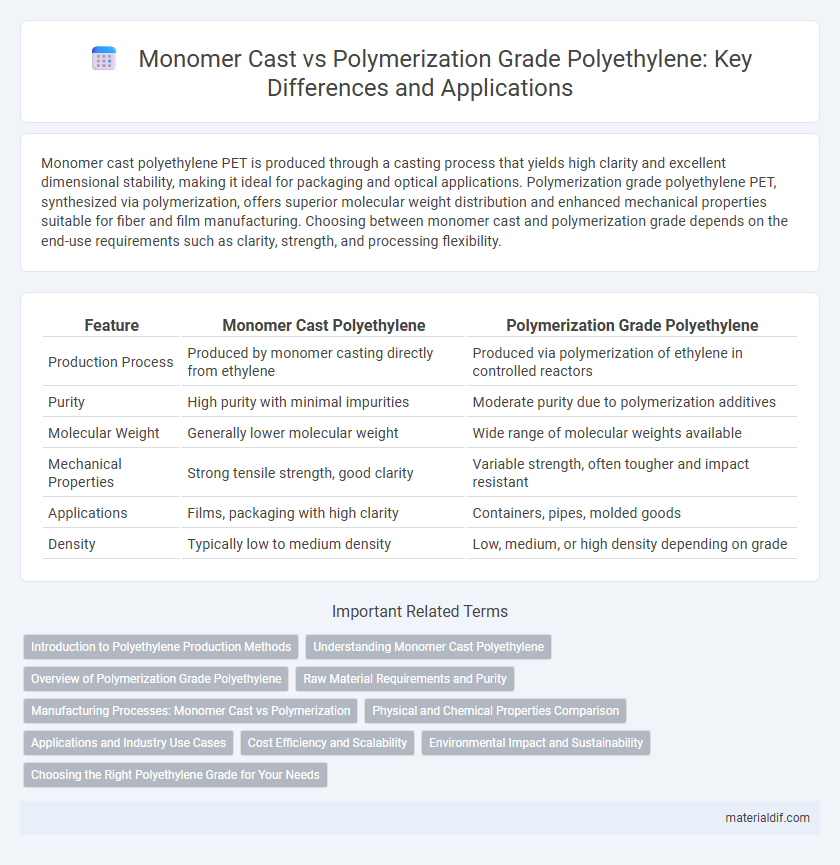

Table of Comparison

| Feature | Monomer Cast Polyethylene | Polymerization Grade Polyethylene |

|---|---|---|

| Production Process | Produced by monomer casting directly from ethylene | Produced via polymerization of ethylene in controlled reactors |

| Purity | High purity with minimal impurities | Moderate purity due to polymerization additives |

| Molecular Weight | Generally lower molecular weight | Wide range of molecular weights available |

| Mechanical Properties | Strong tensile strength, good clarity | Variable strength, often tougher and impact resistant |

| Applications | Films, packaging with high clarity | Containers, pipes, molded goods |

| Density | Typically low to medium density | Low, medium, or high density depending on grade |

Introduction to Polyethylene Production Methods

Monomer cast polyethylene is produced by polymerizing ethylene directly in the presence of a catalyst within a monomer-rich environment, resulting in high-purity, low-contaminant polymer ideal for film applications. Polymerization grade polyethylene involves controlled polymerization processes such as slurry, gas-phase, or solution polymerization techniques, optimized to achieve specific molecular weight distributions and mechanical properties. Choosing between monomer cast and polymerization grade methods depends on targeted product performance, production efficiency, and application requirements in industries like packaging and automotive.

Understanding Monomer Cast Polyethylene

Monomer cast polyethylene is produced by polymerizing ethylene monomers directly in a casting process, resulting in a material with superior clarity, higher crystallinity, and enhanced mechanical properties compared to polymerization grade polyethylene. This method allows for precise control over polymer structure, yielding films and sheets with improved barrier performance and durability. Understanding monomer cast polyethylene is essential for applications requiring excellent optical quality and strength, such as food packaging and protective coverings.

Overview of Polymerization Grade Polyethylene

Polymerization grade polyethylene is characterized by its high purity and specific molecular weight distribution, making it ideal for advanced manufacturing processes that require consistent material properties. It is produced through controlled polymerization methods, ensuring minimal impurities and enhanced performance in applications such as films, packaging, and injection molding. This grade offers superior mechanical strength, clarity, and chemical resistance compared to monomer cast polyethylene, which is typically less uniform and contains more residual monomers.

Raw Material Requirements and Purity

Monomer cast polyethylene requires raw materials with ultra-high purity to ensure defect-free film formation and optical clarity, demanding stringent control of monomer contaminants and catalyst residues. Polymerization grade polyethylene allows for slightly lower purity levels but necessitates precise control over molecular weight distribution and comonomer incorporation to achieve desired mechanical and chemical properties. Both grades depend on high-quality ethylene feedstock, but monomer cast applications prioritize purity over cost, while polymerization grade balances raw material purity with polymerization efficiency.

Manufacturing Processes: Monomer Cast vs Polymerization

Monomer cast polyethylene is produced by polymerizing ethylene monomers directly within a contained casting process, resulting in a highly pure and uniform film with excellent optical clarity and mechanical properties. Polymerization-grade polyethylene, on the other hand, involves bulk or gas-phase polymerization reactors where ethylene monomers are converted into polymer resins that are later processed into films or molded products. The monomer cast process offers finer control over molecular weight distribution and film thickness, while polymerization-grade materials provide versatility for various industrial applications due to their tailored polymer chain structures.

Physical and Chemical Properties Comparison

Monomer Cast polyethylene exhibits higher clarity and improved tensile strength compared to Polymerization Grade due to its slower polymerization process and better molecular orientation. Polymerization Grade generally presents a higher molecular weight distribution, resulting in enhanced impact resistance and thermal stability. Chemical properties such as density and crystallinity vary slightly, with Monomer Cast showing greater uniformity, making it ideal for applications requiring transparency and mechanical precision.

Applications and Industry Use Cases

Monomer cast polyethylene is primarily used in applications requiring high clarity, excellent chemical resistance, and superior surface finish, making it ideal for medical devices, food packaging, and cosmetic containers. Polymerization-grade polyethylene offers versatility in industries such as automotive, construction, and consumer goods due to its customizable mechanical properties and cost-effectiveness. Different polymerization techniques enable tailored molecular weights and densities, optimizing the polyethylene type for specific industrial use cases.

Cost Efficiency and Scalability

Monomer cast polyethylene offers cost efficiency by using monomer casting techniques that reduce processing steps and energy consumption, leading to lower production costs. Polymerization grade polyethylene, produced through controlled polymerization processes, allows for high scalability and consistent material properties suitable for large-scale industrial applications. Choosing between monomer cast and polymerization grade polyethylene depends on balancing lower upfront costs with the need for scalable, uniform polymer production in various manufacturing sectors.

Environmental Impact and Sustainability

Monomer cast polyethylene offers lower emissions during production due to its high purities and efficient polymerization processes, reducing environmental impact compared to traditional polymerization-grade resins. Polymerization-grade polyethylene often requires more extensive refining, increasing energy consumption and generating higher greenhouse gas emissions. Sustainable manufacturing trends prioritize monomer cast polyethylene for its potential in minimizing carbon footprint and enhancing recyclability in plastic applications.

Choosing the Right Polyethylene Grade for Your Needs

Selecting the right polyethylene grade depends on the intended application and processing method. Monomer cast polyethylene offers superior clarity and toughness, ideal for high-performance films and packaging, while polymerization-grade polyethylene provides versatile molecular weights suited for injection molding, extrusion, and blow molding. Understanding the differences in molecular structure and properties ensures optimal mechanical performance and cost-efficiency for specific industrial needs.

Monomer Cast vs Polymerization Grade Infographic

materialdif.com

materialdif.com