Polyethylene wax is a low molecular weight polymer known for its lubricating properties and high melting point, making it ideal for coatings, inks, and cosmetics. Polyethylene resin, on the other hand, consists of higher molecular weight polymers used extensively in packaging, containers, and plastic films due to its strength and durability. The key difference lies in their molecular structure and applications, with wax providing surface modification and resin offering structural support.

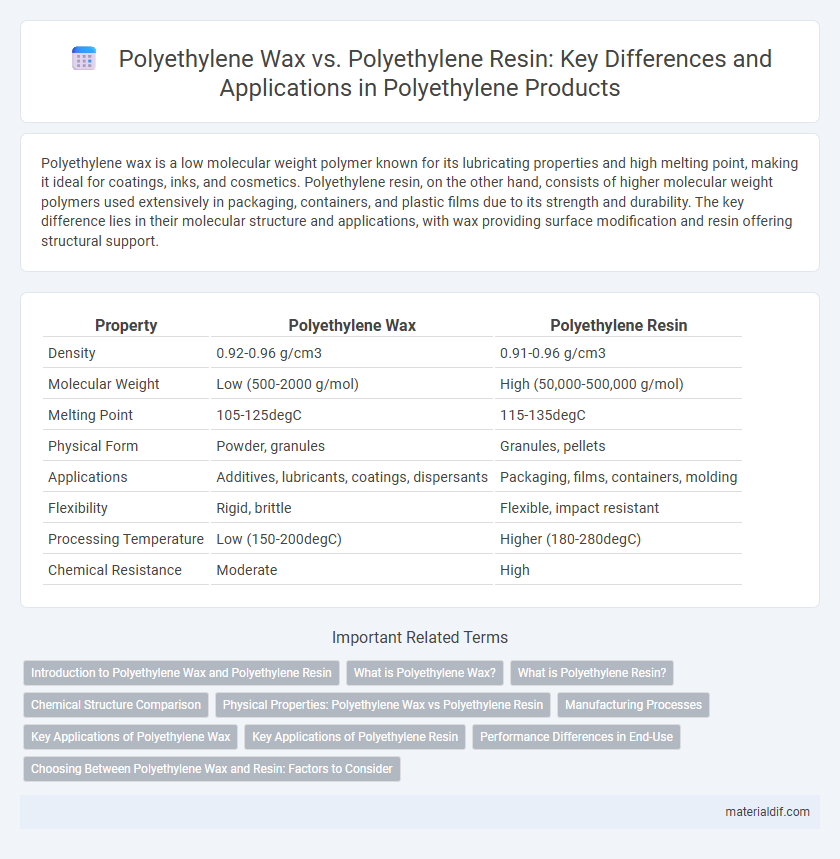

Table of Comparison

| Property | Polyethylene Wax | Polyethylene Resin |

|---|---|---|

| Density | 0.92-0.96 g/cm3 | 0.91-0.96 g/cm3 |

| Molecular Weight | Low (500-2000 g/mol) | High (50,000-500,000 g/mol) |

| Melting Point | 105-125degC | 115-135degC |

| Physical Form | Powder, granules | Granules, pellets |

| Applications | Additives, lubricants, coatings, dispersants | Packaging, films, containers, molding |

| Flexibility | Rigid, brittle | Flexible, impact resistant |

| Processing Temperature | Low (150-200degC) | Higher (180-280degC) |

| Chemical Resistance | Moderate | High |

Introduction to Polyethylene Wax and Polyethylene Resin

Polyethylene wax is a low molecular weight material derived from the polymerization or thermal decomposition of polyethylene resin, characterized by its fine particle size and high melting point. Polyethylene resin, a high molecular weight polymer, is widely used in manufacturing films, containers, and pipes due to its excellent chemical resistance and durability. The primary distinction lies in their molecular weight and physical properties, influencing applications in coatings, adhesives, and molding compounds.

What is Polyethylene Wax?

Polyethylene wax is a low molecular weight polyethylene characterized by a waxy appearance and lower melting point, primarily used as a processing aid, lubricant, and additive in coatings, inks, and plastics. It differs from polyethylene resin, which has a higher molecular weight and is used to manufacture bulk plastic products like films, containers, and pipes. Polyethylene wax improves surface properties, enhances processing, and provides lubricity, whereas polyethylene resin forms the structural base of plastic materials.

What is Polyethylene Resin?

Polyethylene resin is a versatile thermoplastic polymer produced through the polymerization of ethylene monomers, characterized by its high molecular weight and solid form used in molding and extrusion applications. It serves as the foundational material for manufacturing plastic films, containers, and pipes due to its strength, chemical resistance, and flexibility. Unlike polyethylene wax, which has lower molecular weight and is used primarily as a lubricant and dispersant, polyethylene resin provides structural integrity and durability in various industrial products.

Chemical Structure Comparison

Polyethylene wax and polyethylene resin differ primarily in molecular weight and branching, where polyethylene wax has a lower molecular weight and shorter polymer chains compared to the high molecular weight, long-chain structure of polyethylene resin. Chemically, both consist of repeating ethylene (-CH2-CH2-) units but vary in crystallinity and density due to differences in branching and chain length, impacting properties like melting point and hardness. The wax exhibits a more linear structure with fewer branches, resulting in lower viscosity and higher surface energy, while the resin's complex branching enhances tensile strength and flexibility.

Physical Properties: Polyethylene Wax vs Polyethylene Resin

Polyethylene wax exhibits a lower molecular weight and melting point, resulting in a harder, more brittle texture compared to polyethylene resin, which has higher molecular weight and greater flexibility. The wax form typically has a melting range of 110-130degC, while resin melts between 120-130degC but offers superior tensile strength and impact resistance. These physical property differences influence their applications, with waxes favoring coatings, polishes, and additives, and resins used for molding, packaging, and films.

Manufacturing Processes

Polyethylene wax is produced through controlled polymerization or thermal degradation of high molecular weight polyethylene resin, resulting in low molecular weight and waxy consistency. Polyethylene resin manufacturing involves polymerizing ethylene monomers using processes like high-pressure polymerization or Ziegler-Natta catalysis to produce a solid, high molecular weight polymer. The differences in molecular weight and processing conditions define polyethylene wax's lower melting point and higher fluidity compared to the more rigid and durable polyethylene resin.

Key Applications of Polyethylene Wax

Polyethylene wax is widely used in industrial applications such as mold release agents, coatings, inks, and plastics processing aids due to its excellent flow properties and low melting point. Unlike polyethylene resin, which is primarily utilized for packaging films, containers, and pipes due to its structural strength and durability, polyethylene wax serves as an additive to improve surface finish and slip characteristics. Key industries benefiting from polyethylene wax include automotive, textiles, adhesives, and cosmetics, where it enhances lubrication, gloss, and compatibility with various polymers.

Key Applications of Polyethylene Resin

Polyethylene resin is widely used in packaging films, containers, and pipes due to its excellent chemical resistance and flexibility. It serves as a primary raw material in the production of plastic bags, bottles, and geomembranes, offering durability and moisture barrier properties. Unlike polyethylene wax, which is primarily used as a lubricant or additive, polyethylene resin's key applications center around structural and functional components in everyday consumer and industrial products.

Performance Differences in End-Use

Polyethylene wax offers lower molecular weight and higher melting points, providing superior surface finish, slip, and abrasion resistance in applications like coatings and inks. Polyethylene resin, with higher molecular weight and better mechanical strength, is preferred for molded products and films requiring durability and impact resistance. The choice between wax and resin depends on specific end-use requirements such as flexibility, tensile strength, and thermal stability.

Choosing Between Polyethylene Wax and Resin: Factors to Consider

Polyethylene wax and polyethylene resin differ significantly in molecular weight, melting point, and application suitability, with wax having lower molecular weight and melting point, making it ideal for coatings, polishes, and additives. Polyethylene resin offers higher molecular weight and structural strength, commonly used in packaging, containers, and films. Key factors for choosing between them include required mechanical properties, processing methods, and the specific end-use environment.

Polyethylene Wax vs Polyethylene Resin Infographic

materialdif.com

materialdif.com