Cross-linked Polyethylene (PEX) offers enhanced thermal resistance and improved chemical stability, making it ideal for plumbing and heating applications. Ultra-High-Molecular-Weight Polyethylene (UHMWPE) features exceptional abrasion resistance and extremely low friction, which is crucial for industrial wear parts and medical implants. Both materials benefit from polyethylene's versatility but serve distinct purposes based on their molecular structure and performance characteristics.

Table of Comparison

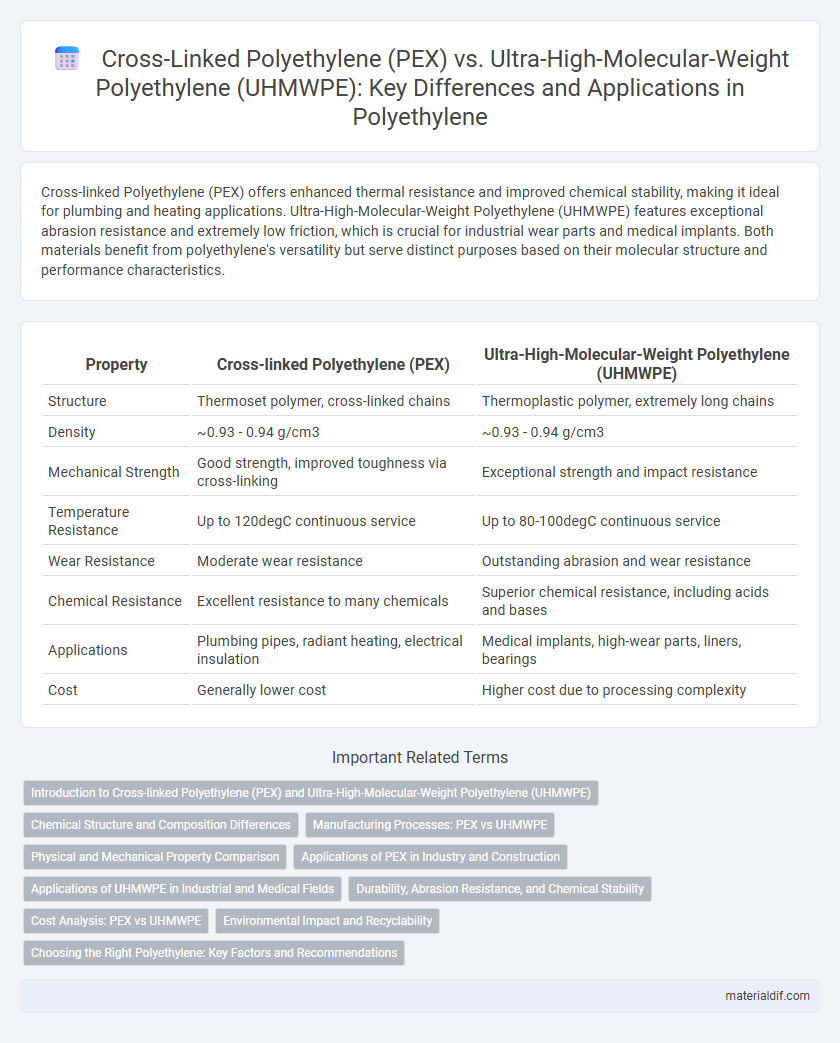

| Property | Cross-linked Polyethylene (PEX) | Ultra-High-Molecular-Weight Polyethylene (UHMWPE) |

|---|---|---|

| Structure | Thermoset polymer, cross-linked chains | Thermoplastic polymer, extremely long chains |

| Density | ~0.93 - 0.94 g/cm3 | ~0.93 - 0.94 g/cm3 |

| Mechanical Strength | Good strength, improved toughness via cross-linking | Exceptional strength and impact resistance |

| Temperature Resistance | Up to 120degC continuous service | Up to 80-100degC continuous service |

| Wear Resistance | Moderate wear resistance | Outstanding abrasion and wear resistance |

| Chemical Resistance | Excellent resistance to many chemicals | Superior chemical resistance, including acids and bases |

| Applications | Plumbing pipes, radiant heating, electrical insulation | Medical implants, high-wear parts, liners, bearings |

| Cost | Generally lower cost | Higher cost due to processing complexity |

Introduction to Cross-linked Polyethylene (PEX) and Ultra-High-Molecular-Weight Polyethylene (UHMWPE)

Cross-linked Polyethylene (PEX) is a thermoset polymer characterized by a three-dimensional network of molecular bonds, enhancing its chemical resistance, thermal stability, and mechanical strength. Ultra-High-Molecular-Weight Polyethylene (UHMWPE) features extremely long polymer chains with a molecular weight typically between 3.5 to 7.5 million g/mol, resulting in exceptional impact strength, wear resistance, and low friction properties. Both materials are widely used in medical, automotive, and industrial applications due to their unique performance attributes tailored to specific engineering demands.

Chemical Structure and Composition Differences

Cross-linked polyethylene (PEX) features a three-dimensional network formed by covalent bonds between polymer chains, enhancing its thermal stability and chemical resistance due to the cross-linking process. Ultra-high-molecular-weight polyethylene (UHMWPE) consists of extremely long polyethylene chains with molecular weights typically between 3.5 to 7.5 million g/mol, resulting in outstanding abrasion resistance and impact strength without cross-linking. The fundamental difference lies in PEX's chemically modified network structure versus UHMWPE's exceptionally high molecular weight linear chains, influencing their mechanical and chemical properties.

Manufacturing Processes: PEX vs UHMWPE

Cross-linked Polyethylene (PEX) is produced through chemical, radiation, or peroxide cross-linking methods that enhance thermal and mechanical properties by creating covalent bonds between polymer chains. Ultra-High-Molecular-Weight Polyethylene (UHMWPE) is synthesized via polymerization processes yielding extremely long polymer chains, which are then processed through compression molding or ram extrusion to achieve high-density, abrasion-resistant material. The manufacturing of PEX involves post-polymerization modification, whereas UHMWPE manufacturing focuses on optimizing polymer chain length and molecular weight during initial synthesis.

Physical and Mechanical Property Comparison

Cross-linked Polyethylene (PEX) exhibits enhanced thermal stability, improved chemical resistance, and superior flexibility due to its three-dimensional network structure, making it ideal for plumbing and radiant heating applications. Ultra-High-Molecular-Weight Polyethylene (UHMWPE) offers exceptional abrasion resistance, high impact strength, and low coefficient of friction, attributed to its extremely long polymer chains and high molecular weight, widely used in medical implants and industrial components. While PEX excels in thermal endurance and flexibility, UHMWPE stands out for mechanical toughness and wear resistance, reflecting their distinct molecular architectures and application-specific performance.

Applications of PEX in Industry and Construction

Cross-linked Polyethylene (PEX) is widely utilized in plumbing, radiant heating systems, and industrial piping due to its enhanced chemical resistance, flexibility, and high-temperature tolerance compared to traditional polyethylene types. Its cross-linked molecular structure provides superior durability and resistance to environmental stress cracking, making it ideal for construction applications requiring long-lasting, leak-resistant materials. PEX's ease of installation and ability to withstand high pressure also contribute to its prominence in residential, commercial, and industrial infrastructure projects.

Applications of UHMWPE in Industrial and Medical Fields

Ultra-High-Molecular-Weight Polyethylene (UHMWPE) excels in industrial applications such as conveyor belts, liners, and wear-resistant machine parts due to its outstanding abrasion resistance and low coefficient of friction. In the medical field, UHMWPE is widely used for orthopedic implants like hip and knee replacements thanks to its biocompatibility and high impact strength. Compared to Cross-linked Polyethylene (PEX), UHMWPE offers superior durability and performance in high-stress environments requiring both mechanical toughness and chemical stability.

Durability, Abrasion Resistance, and Chemical Stability

Cross-linked polyethylene (PEX) exhibits superior durability and chemical stability due to its networked polymer structure, making it highly resistant to heat and oxidation. Ultra-high-molecular-weight polyethylene (UHMWPE) excels in abrasion resistance and impact toughness, attributed to its extremely long polymer chains and high molecular weight. While PEX is ideal for plumbing and heating applications requiring thermal and chemical endurance, UHMWPE is preferred in industrial components demanding exceptional wear resistance and mechanical strength.

Cost Analysis: PEX vs UHMWPE

Cross-linked Polyethylene (PEX) typically offers a lower initial material cost compared to Ultra-High-Molecular-Weight Polyethylene (UHMWPE), making it more affordable for general plumbing and insulation applications. UHMWPE commands a higher price due to its exceptional wear resistance, impact strength, and chemical stability, driving up costs in specialized industrial and medical uses. Considering lifecycle expenses, PEX may incur higher maintenance and replacement costs, whereas UHMWPE often provides superior long-term durability and reduced operational costs despite its upfront investment.

Environmental Impact and Recyclability

Cross-linked polyethylene (PEX) exhibits limited recyclability due to its chemically bonded polymer chains, which resist melting and reshaping, leading to increased environmental challenges in waste management. In contrast, ultra-high-molecular-weight polyethylene (UHMWPE) is more recyclable, benefiting from its thermoplastic nature that allows efficient reprocessing and reduced ecological footprint. Both materials contribute to plastic waste concerns, but UHMWPE's higher recyclability enhances its sustainability profile compared to the more durable but less recyclable PEX.

Choosing the Right Polyethylene: Key Factors and Recommendations

Cross-linked Polyethylene (PEX) features enhanced thermal resistance and flexibility, making it ideal for plumbing and radiant heating systems, whereas Ultra-High-Molecular-Weight Polyethylene (UHMWPE) offers exceptional wear resistance and impact strength, suited for industrial applications like conveyor belts and medical implants. Selecting the right polyethylene depends on factors such as mechanical stress, temperature exposure, and chemical resistance requirements. For high-temperature and flexible applications, PEX is recommended, while UHMWPE excels in heavy-duty, abrasion-prone environments.

Cross-linked Polyethylene (PEX) vs Ultra-High-Molecular-Weight Polyethylene (UHMWPE) Infographic

materialdif.com

materialdif.com