Polyethylene sheets offer greater thickness and durability compared to polyethylene films, making them ideal for heavy-duty applications like construction and industrial use. Polyethylene films are thinner, more flexible, and often used for packaging, wrapping, and moisture barriers where lightweight material is essential. Choosing between polyethylene sheet and film depends on the required strength, flexibility, and specific application needs.

Table of Comparison

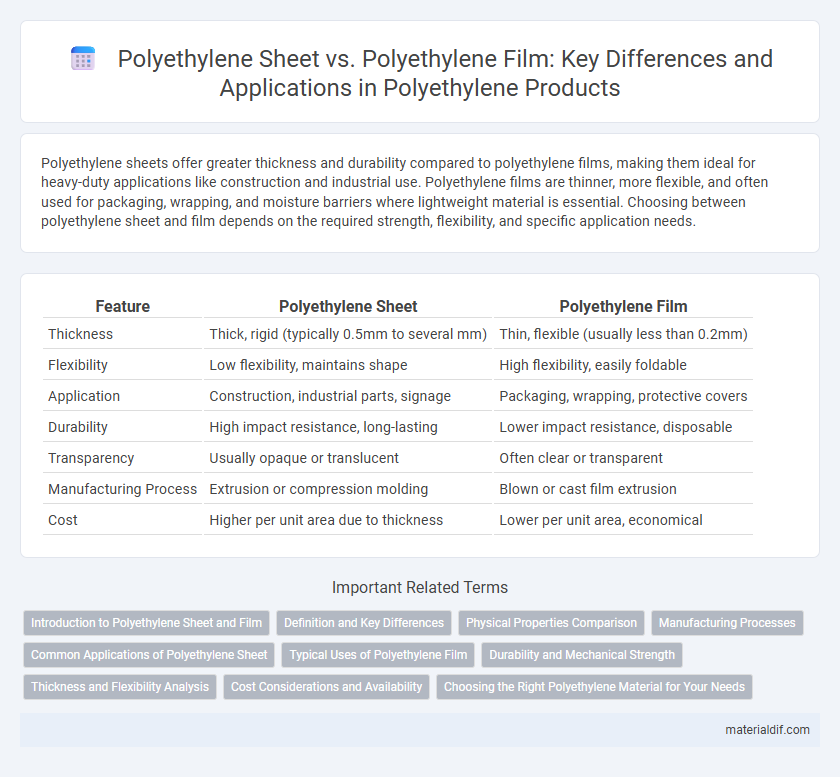

| Feature | Polyethylene Sheet | Polyethylene Film |

|---|---|---|

| Thickness | Thick, rigid (typically 0.5mm to several mm) | Thin, flexible (usually less than 0.2mm) |

| Flexibility | Low flexibility, maintains shape | High flexibility, easily foldable |

| Application | Construction, industrial parts, signage | Packaging, wrapping, protective covers |

| Durability | High impact resistance, long-lasting | Lower impact resistance, disposable |

| Transparency | Usually opaque or translucent | Often clear or transparent |

| Manufacturing Process | Extrusion or compression molding | Blown or cast film extrusion |

| Cost | Higher per unit area due to thickness | Lower per unit area, economical |

Introduction to Polyethylene Sheet and Film

Polyethylene sheets are thick, rigid plastic materials primarily used for structural applications, offering excellent chemical resistance and impact strength. Polyethylene films are thin, flexible sheets commonly utilized for packaging, vapor barriers, and protective coverings due to their lightweight and transparency. Both forms share the same polymer base but differ in thickness, flexibility, and typical industrial uses, optimizing them for distinct functional requirements.

Definition and Key Differences

Polyethylene sheet is a thick, rigid material commonly used for applications requiring durability and structural support, whereas polyethylene film is a thin, flexible plastic primarily utilized for packaging, wrapping, and protective coverings. The key differences lie in their thickness, rigidity, and typical uses, with sheets offering higher impact resistance and films providing better conformability and transparency. Both are made from the same polymer resin but are manufactured through different processes to meet varying industrial and commercial needs.

Physical Properties Comparison

Polyethylene sheets possess greater thickness and rigidity compared to polyethylene films, which are typically thin and flexible for packaging applications. The density of polyethylene sheets ranges from 0.91 to 0.96 g/cm3, providing enhanced tensile strength and impact resistance, while polyethylene films have lower tensile strength but higher elongation at break, allowing for better stretchability. Thermal properties also differ, with sheets offering higher heat distortion temperatures, making them suitable for structural uses, whereas films excel in conformability and barrier properties.

Manufacturing Processes

Polyethylene sheets are produced through extrusion and calendaring processes, which involve melting the polymer and forming it into thick, rigid sheets with uniform thickness. Polyethylene films are typically manufactured by blown or cast film extrusion, resulting in thin, flexible, and transparent materials ideal for packaging. The key difference lies in the thickness and flexibility achieved by these processes, with sheets optimized for durability and films for lightweight applications.

Common Applications of Polyethylene Sheet

Polyethylene sheets are widely used in construction, agriculture, and packaging due to their durability, chemical resistance, and excellent moisture barrier properties. Common applications include protective barriers, vapor retarders, insulation covers, and greenhouse glazing. Unlike polyethylene film, which is typically thin and flexible for wrapping and bags, polyethylene sheets provide rigid structural support and are ideal for heavy-duty protection and industrial uses.

Typical Uses of Polyethylene Film

Polyethylene film is primarily used for packaging applications, including food wrap, agricultural covers, and protective barriers due to its flexibility and moisture resistance. It is also common in industrial settings for shrink wrap and pallet covers, providing lightweight yet durable protection. In contrast, polyethylene sheets are thicker and used in construction, insulation, and surface protection where rigidity and strength are required.

Durability and Mechanical Strength

Polyethylene sheets exhibit superior durability and mechanical strength compared to polyethylene films due to their thicker gauge and denser molecular structure. Sheets provide greater resistance to impact, puncture, and wear, making them ideal for heavy-duty applications requiring structural integrity. Conversely, polyethylene films, being thinner and more flexible, prioritize flexibility and versatility but offer less mechanical robustness.

Thickness and Flexibility Analysis

Polyethylene sheets exhibit greater thickness, typically ranging from 0.5 mm to over 10 mm, providing enhanced rigidity and impact resistance compared to polyethylene films, which are usually less than 0.3 mm thick and offer superior flexibility. The increased thickness of polyethylene sheets results in reduced flexibility, making them ideal for structural applications, whereas polyethylene films maintain high pliability suitable for packaging and wrapping uses. Thickness directly influences the mechanical properties, with sheets designed for durability and films optimized for conformability and lightweight protection.

Cost Considerations and Availability

Polyethylene sheets generally have higher production costs due to their thicker gauge and greater durability compared to polyethylene films, which are thinner and cheaper to manufacture. Availability of polyethylene sheets tends to be less widespread, often requiring specialized suppliers or custom orders, whereas polyethylene films are mass-produced and readily available in various sizes and thicknesses. Cost considerations favor polyethylene films for applications needing economical, lightweight materials, while sheets are preferred for heavy-duty uses despite their higher price and more limited availability.

Choosing the Right Polyethylene Material for Your Needs

Polyethylene sheets offer higher durability and rigidity, making them ideal for applications requiring structural support, while polyethylene films provide flexibility and are suited for packaging, wrapping, or protective covers. Consider factors such as thickness, tensile strength, and intended use; sheets are typically measured in millimeters for heavy-duty tasks, whereas films are measured in microns for lighter, flexible needs. Selecting the appropriate polyethylene material ensures optimal performance, cost-efficiency, and suitability for your specific industrial or commercial application.

Polyethylene sheet vs Polyethylene film Infographic

materialdif.com

materialdif.com