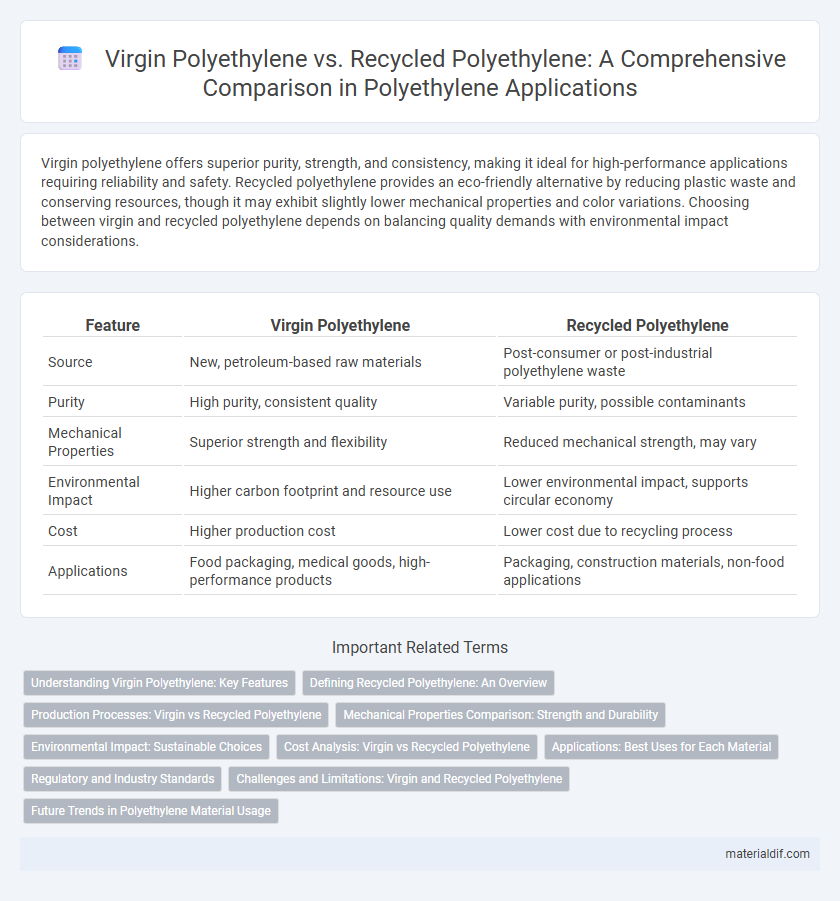

Virgin polyethylene offers superior purity, strength, and consistency, making it ideal for high-performance applications requiring reliability and safety. Recycled polyethylene provides an eco-friendly alternative by reducing plastic waste and conserving resources, though it may exhibit slightly lower mechanical properties and color variations. Choosing between virgin and recycled polyethylene depends on balancing quality demands with environmental impact considerations.

Table of Comparison

| Feature | Virgin Polyethylene | Recycled Polyethylene |

|---|---|---|

| Source | New, petroleum-based raw materials | Post-consumer or post-industrial polyethylene waste |

| Purity | High purity, consistent quality | Variable purity, possible contaminants |

| Mechanical Properties | Superior strength and flexibility | Reduced mechanical strength, may vary |

| Environmental Impact | Higher carbon footprint and resource use | Lower environmental impact, supports circular economy |

| Cost | Higher production cost | Lower cost due to recycling process |

| Applications | Food packaging, medical goods, high-performance products | Packaging, construction materials, non-food applications |

Understanding Virgin Polyethylene: Key Features

Virgin polyethylene is produced from pure petrochemical feedstocks, offering consistent molecular structure and superior mechanical properties such as tensile strength and flexibility. It exhibits high purity, ensuring optimal performance in applications requiring stringent quality standards like food packaging and medical devices. The absence of contaminants and additives found in recycled polyethylene results in enhanced clarity, durability, and chemical resistance.

Defining Recycled Polyethylene: An Overview

Recycled polyethylene is derived from post-consumer or post-industrial plastic waste that undergoes processes such as collection, sorting, cleaning, and reprocessing to create new polyethylene materials. Unlike virgin polyethylene, which is produced from petrochemical raw materials through polymerization, recycled polyethylene reduces environmental impact by diverting plastic waste from landfills and lowering carbon emissions. The quality and properties of recycled polyethylene depend on the source material and processing methods, influencing its applications in packaging, construction, and manufacturing.

Production Processes: Virgin vs Recycled Polyethylene

Virgin polyethylene is produced through polymerization of ethylene derived from petrochemical feedstocks, ensuring high purity and consistent molecular structure. Recycled polyethylene involves collection, sorting, cleaning, and reprocessing of post-consumer or post-industrial polyethylene waste, which may lead to variations in molecular weight and potential contamination. Advanced recycling techniques such as chemical recycling are emerging to improve the quality and restore properties close to virgin polyethylene.

Mechanical Properties Comparison: Strength and Durability

Virgin polyethylene exhibits superior mechanical properties, with higher tensile strength and enhanced durability compared to recycled polyethylene. Recycled polyethylene often contains impurities and undergoes degradation during processing, resulting in reduced impact resistance and lower elongation at break. Applications demanding consistent strength and longevity typically prefer virgin polyethylene to ensure optimal performance.

Environmental Impact: Sustainable Choices

Virgin polyethylene production relies on fossil fuels, leading to higher carbon emissions and greater resource depletion compared to recycled polyethylene. Recycled polyethylene significantly reduces landfill waste and lowers greenhouse gas emissions by reprocessing existing materials rather than extracting new raw inputs. Choosing recycled polyethylene supports sustainability by minimizing environmental impact and promoting circular economy principles in plastic manufacturing.

Cost Analysis: Virgin vs Recycled Polyethylene

Virgin polyethylene typically incurs higher production costs due to raw material extraction and purification processes, whereas recycled polyethylene offers cost advantages by utilizing post-consumer or post-industrial waste streams. Market prices for virgin polyethylene often reflect tighter supply chains and consistently high purity levels, which drive up overall expenses compared to recycled variants. Cost analysis reveals recycled polyethylene can reduce material expenses by up to 30%, making it a financially attractive option for industries prioritizing sustainability without compromising budget constraints.

Applications: Best Uses for Each Material

Virgin polyethylene offers superior purity and mechanical properties, making it ideal for food packaging, medical devices, and high-performance industrial applications. Recycled polyethylene is well-suited for non-food packaging, construction materials, and automotive components where slightly lower material performance is acceptable. Selecting between virgin and recycled polyethylene depends on application requirements for safety, durability, and regulatory compliance.

Regulatory and Industry Standards

Virgin polyethylene complies strictly with ASTM D3350 standards, ensuring consistent quality and mechanical properties, making it ideal for medical and food-grade applications where regulatory compliance is critical. Recycled polyethylene must meet specific EPA regulations and ISO 22000 standards to verify safety, purity, and performance, often requiring advanced sorting and cleaning processes to remove contaminants. Industry standards like FDA 21 CFR for food contact materials set stringent limits that recycled polyethylene must satisfy to be approved for consumer use.

Challenges and Limitations: Virgin and Recycled Polyethylene

Virgin polyethylene offers consistent quality and superior mechanical properties, essential for high-performance applications, but its production heavily relies on non-renewable fossil fuels, raising environmental concerns. Recycled polyethylene faces challenges such as contamination, variable molecular weight distribution, and degradation of polymer chains, which limit its mechanical strength and restrict its use in food-grade or high-barrier packaging. Both virgin and recycled polyethylene encounter limitations in maintaining long-term durability and recyclability without compromising product safety or environmental impact.

Future Trends in Polyethylene Material Usage

Future trends in polyethylene material usage indicate a significant shift toward integrating recycled polyethylene (rPE) due to increasing environmental regulations and consumer demand for sustainable products. Innovations in chemical recycling and advanced sorting technologies are improving the quality and consistency of recycled polyethylene, enabling broader application across packaging, automotive, and construction industries. Virgin polyethylene (vPE) remains essential for high-performance applications requiring purity and specific mechanical properties, but hybrid blends of virgin and recycled polyethylene are gaining traction to balance sustainability with performance.

Virgin Polyethylene vs Recycled Polyethylene Infographic

materialdif.com

materialdif.com