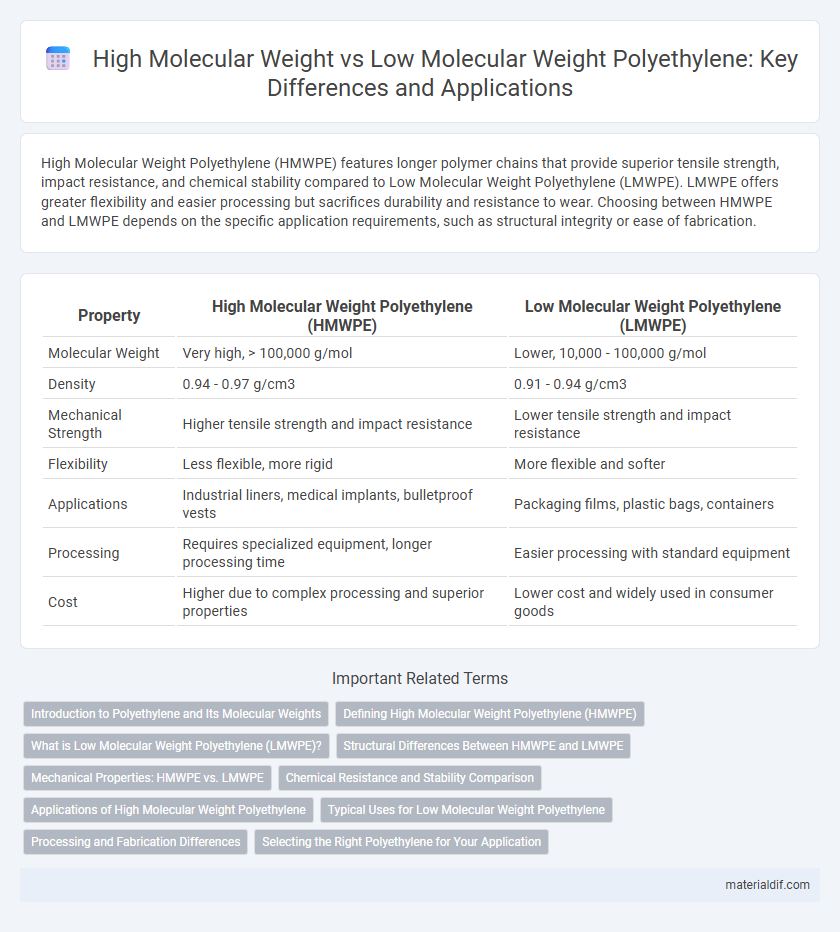

High Molecular Weight Polyethylene (HMWPE) features longer polymer chains that provide superior tensile strength, impact resistance, and chemical stability compared to Low Molecular Weight Polyethylene (LMWPE). LMWPE offers greater flexibility and easier processing but sacrifices durability and resistance to wear. Choosing between HMWPE and LMWPE depends on the specific application requirements, such as structural integrity or ease of fabrication.

Table of Comparison

| Property | High Molecular Weight Polyethylene (HMWPE) | Low Molecular Weight Polyethylene (LMWPE) |

|---|---|---|

| Molecular Weight | Very high, > 100,000 g/mol | Lower, 10,000 - 100,000 g/mol |

| Density | 0.94 - 0.97 g/cm3 | 0.91 - 0.94 g/cm3 |

| Mechanical Strength | Higher tensile strength and impact resistance | Lower tensile strength and impact resistance |

| Flexibility | Less flexible, more rigid | More flexible and softer |

| Applications | Industrial liners, medical implants, bulletproof vests | Packaging films, plastic bags, containers |

| Processing | Requires specialized equipment, longer processing time | Easier processing with standard equipment |

| Cost | Higher due to complex processing and superior properties | Lower cost and widely used in consumer goods |

Introduction to Polyethylene and Its Molecular Weights

Polyethylene is a versatile polymer categorized by its molecular weight, significantly influencing its properties and applications. High molecular weight polyethylene (HMWPE) features longer polymer chains, resulting in enhanced strength, durability, and chemical resistance, making it ideal for heavy-duty uses such as industrial piping and bulletproof vests. In contrast, low molecular weight polyethylene (LMWPE) has shorter chains, providing greater flexibility and easier processing, commonly utilized in packaging films and lightweight containers.

Defining High Molecular Weight Polyethylene (HMWPE)

High Molecular Weight Polyethylene (HMWPE) is characterized by its significantly longer polymer chains compared to Low Molecular Weight Polyethylene (LMWPE), resulting in enhanced tensile strength, abrasion resistance, and chemical stability. This polymer's molecular weight typically exceeds several hundred thousand g/mol, providing superior performance in demanding applications such as medical implants, ballistic protection, and industrial liners. HMWPE's dense molecular structure contributes to its exceptional impact resistance and low coefficient of friction, making it a preferred material in high-stress environments.

What is Low Molecular Weight Polyethylene (LMWPE)?

Low Molecular Weight Polyethylene (LMWPE) is a type of polyethylene characterized by shorter polymer chains and lower molecular weight, resulting in a softer and more flexible material. LMWPE is commonly used in applications requiring easy processability and good impact resistance, such as film packaging, squeeze bottles, and coatings. Its lower density and tensile strength compared to High Molecular Weight Polyethylene (HMWPE) make it suitable for products needing flexibility rather than high mechanical strength.

Structural Differences Between HMWPE and LMWPE

High Molecular Weight Polyethylene (HMWPE) consists of long polymer chains with a high degree of linearity and minimal branching, resulting in enhanced tensile strength and impact resistance compared to Low Molecular Weight Polyethylene (LMWPE). LMWPE features shorter polymer chains and more chain branching, which decreases density and crystallinity, leading to lower mechanical strength but greater flexibility. The structural differences fundamentally influence their applications, with HMWPE preferred for high-performance uses requiring durability and LMWPE suited for flexible packaging and films.

Mechanical Properties: HMWPE vs. LMWPE

High Molecular Weight Polyethylene (HMWPE) exhibits superior tensile strength and impact resistance compared to Low Molecular Weight Polyethylene (LMWPE), making it ideal for applications requiring durability. HMWPE's enhanced molecular chain length contributes to higher abrasion resistance and better fatigue performance. In contrast, LMWPE offers greater flexibility and ease of processing but has lower mechanical strength and wear resistance.

Chemical Resistance and Stability Comparison

High Molecular Weight Polyethylene (HMWPE) exhibits superior chemical resistance and enhanced stability compared to Low Molecular Weight Polyethylene (LMWPE), due to its longer polymer chains and higher crystallinity. This structural difference results in improved resistance to solvents, acids, and bases, making HMWPE ideal for demanding industrial applications. LMWPE, while more flexible, generally shows lower chemical resistance and stability under harsh environmental conditions.

Applications of High Molecular Weight Polyethylene

High Molecular Weight Polyethylene (HMWPE) exhibits superior tensile strength and abrasion resistance compared to Low Molecular Weight Polyethylene (LMWPE), making it ideal for applications in high-performance industrial components and protective gear. HMWPE is extensively used in ballistic armor, medical prosthetics, and high-strength ropes due to its excellent durability and lightweight nature. Its resistance to chemical corrosion and impact also enables its use in pipelines, storage tanks, and heavy-duty containers where robustness is critical.

Typical Uses for Low Molecular Weight Polyethylene

Low Molecular Weight Polyethylene (LMWPE) is commonly used in film applications such as plastic bags, shrink wraps, and packaging films due to its excellent flexibility and transparency. It also finds applications in coatings, adhesives, and wire coatings because of its lower density and ease of processing. LMWPE's characteristic lower tensile strength compared to High Molecular Weight Polyethylene makes it ideal for products requiring pliability rather than high mechanical strength.

Processing and Fabrication Differences

High Molecular Weight Polyethylene (HMWPE) offers superior mechanical strength and abrasion resistance, making it ideal for high-performance applications but requiring higher processing temperatures and specialized extrusion equipment due to its increased viscosity. Low Molecular Weight Polyethylene (LMWPE) processes more easily with standard molding and extrusion techniques, enabling faster fabrication and better flow characteristics for thin films and coatings. Differences in molecular weight directly influence melt flow index, thermal stability, and crystallinity, which dictate appropriate processing parameters and fabrication methods for each polyethylene type.

Selecting the Right Polyethylene for Your Application

High Molecular Weight Polyethylene (HMWPE) offers superior strength, abrasion resistance, and impact toughness, making it ideal for heavy-duty applications like industrial liners and medical devices. Low Molecular Weight Polyethylene (LMWPE) provides easier processing and flexibility, suitable for packaging films and injection molding. Selecting the right polyethylene depends on balancing mechanical requirements with manufacturing constraints to optimize performance and cost-efficiency.

High Molecular Weight Polyethylene vs Low Molecular Weight Polyethylene Infographic

materialdif.com

materialdif.com