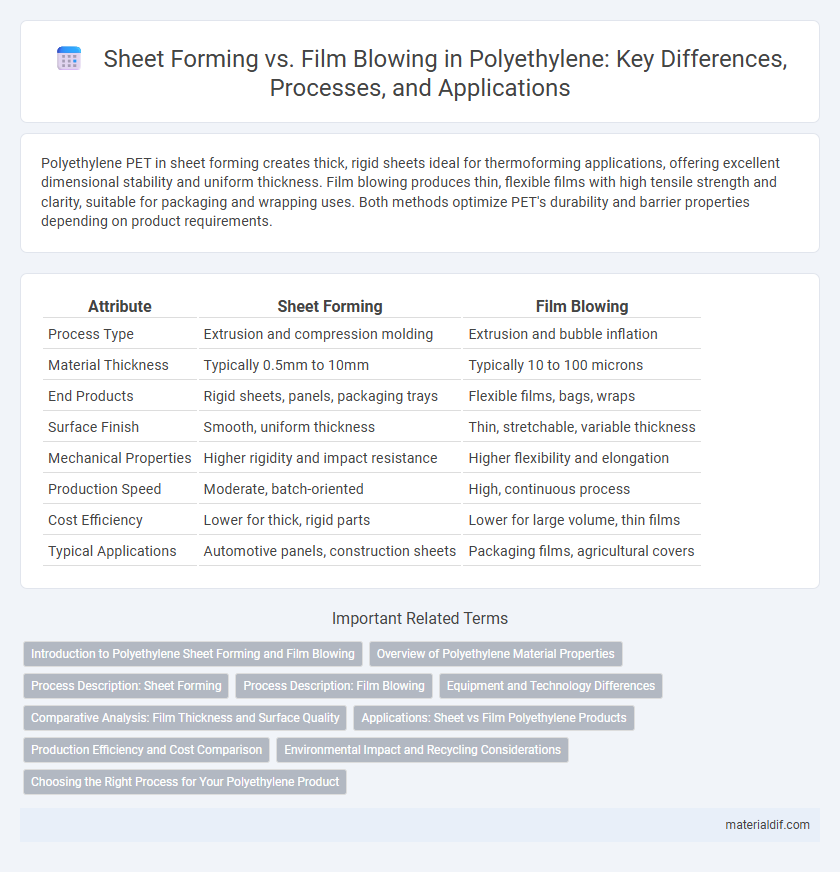

Polyethylene PET in sheet forming creates thick, rigid sheets ideal for thermoforming applications, offering excellent dimensional stability and uniform thickness. Film blowing produces thin, flexible films with high tensile strength and clarity, suitable for packaging and wrapping uses. Both methods optimize PET's durability and barrier properties depending on product requirements.

Table of Comparison

| Attribute | Sheet Forming | Film Blowing |

|---|---|---|

| Process Type | Extrusion and compression molding | Extrusion and bubble inflation |

| Material Thickness | Typically 0.5mm to 10mm | Typically 10 to 100 microns |

| End Products | Rigid sheets, panels, packaging trays | Flexible films, bags, wraps |

| Surface Finish | Smooth, uniform thickness | Thin, stretchable, variable thickness |

| Mechanical Properties | Higher rigidity and impact resistance | Higher flexibility and elongation |

| Production Speed | Moderate, batch-oriented | High, continuous process |

| Cost Efficiency | Lower for thick, rigid parts | Lower for large volume, thin films |

| Typical Applications | Automotive panels, construction sheets | Packaging films, agricultural covers |

Introduction to Polyethylene Sheet Forming and Film Blowing

Polyethylene sheet forming involves heating polymer pellets until molten and then pressing or rolling them into flat sheets with controlled thickness, commonly used for packaging, containers, and industrial applications. Film blowing extrudes molten polyethylene through a circular die, inflates it into a thin tube, and cools it to produce flexible, lightweight films widely utilized for plastic bags, packaging wraps, and agricultural covers. Comparing techniques, sheet forming achieves higher rigidity and thickness uniformity, whereas film blowing excels in producing versatile, stretchable films with excellent barrier properties.

Overview of Polyethylene Material Properties

Polyethylene exhibits excellent chemical resistance, flexibility, and impact strength, making it ideal for both sheet forming and film blowing processes. Sheet forming produces thicker, rigid products with high tensile strength and dimensional stability, while film blowing yields thin, flexible films with superior elongation and clarity. The choice between methods depends on desired mechanical properties, thickness, and end-use applications such as packaging or industrial liners.

Process Description: Sheet Forming

Sheet forming in polyethylene manufacturing involves melting the polymer resin and extruding it through a flat die to create continuous sheets of varying thickness. The process allows precise control over sheet dimensions, surface texture, and mechanical properties, making it ideal for applications such as packaging, thermoforming, and industrial liners. Unlike film blowing, sheet forming produces thicker, more uniform sheets with improved tensile strength and optical clarity.

Process Description: Film Blowing

Film blowing is a process where molten polyethylene is extruded through a circular die to form a thin tubular film, which is then inflated with air to stretch and thin the material uniformly. This technique creates polyethylene films with excellent strength, clarity, and flexibility, making it ideal for packaging applications. The continuous inflation allows precise control over film thickness and width, enhancing material efficiency and product quality.

Equipment and Technology Differences

Sheet forming of polyethylene utilizes heavy-duty calendering machines or extrusion rollers to produce thick, uniform sheets with precise thickness control, while film blowing employs tubular extrusion and air inflation technology to create thin, flexible films with high tensile strength. Sheet forming equipment is designed for smooth surfaces and dimensional stability in applications such as thermoforming and packaging, whereas film blowing machines focus on bubble integrity and bubble collapse prevention to achieve optimal film clarity and elongation properties. The technological distinction lies in the mechanical processes: sheet forming relies on pressure and mechanical rolling, while film blowing depends on controlled air flow and cooling rates during bubble expansion.

Comparative Analysis: Film Thickness and Surface Quality

Film blowing produces polyethylene films with variable thickness due to the inflation process, often resulting in lower uniformity compared to sheet forming, which yields consistently thicker and more uniform sheets. Surface quality in sheet forming is generally superior, offering a smoother finish with fewer defects, whereas film blowing can introduce surface irregularities from air contact and cooling rates. The choice between methods depends on the required film thickness precision and surface finish, with sheet forming favored for applications demanding high-quality, consistent surfaces.

Applications: Sheet vs Film Polyethylene Products

Polyethylene sheet forming produces thick, rigid sheets ideal for applications such as packaging trays, containers, and automotive parts, offering enhanced durability and dimensional stability. Film blowing creates thin, flexible films widely used in agricultural covers, grocery bags, and food packaging, providing excellent clarity and moisture barriers. The distinct manufacturing processes tailor polyethylene to specific end uses, optimizing performance characteristics for sheet or film products.

Production Efficiency and Cost Comparison

Sheet forming of polyethylene typically offers higher production efficiency due to faster cycle times and reduced material waste compared to film blowing. Film blowing involves complex control of bubble formation and cooling rates, often resulting in increased energy consumption and higher operational costs. Cost analysis reveals sheet forming is generally more economical for thicker products, while film blowing remains competitive for thin, flexible films requiring lower material usage.

Environmental Impact and Recycling Considerations

Sheet forming of polyethylene generates less greenhouse gas emissions compared to film blowing due to lower energy consumption during production. Recycling processes for polyethylene sheets are more efficient, as sheets have consistent thickness and fewer contaminants than blown films. Film blowing produces thinner materials that are prone to tearing and contamination, complicating recycling and increasing environmental waste.

Choosing the Right Process for Your Polyethylene Product

Sheet forming offers precise thickness control and excellent surface finish, ideal for applications requiring rigidity and dimensional stability in polyethylene products. Film blowing provides superior tensile strength and flexibility with uniform thickness, suited for packaging films and bags needing high durability and clarity. Selecting between sheet forming and film blowing depends on the product's mechanical properties, end-use requirements, and production volume.

Sheet Forming vs Film Blowing Infographic

materialdif.com

materialdif.com