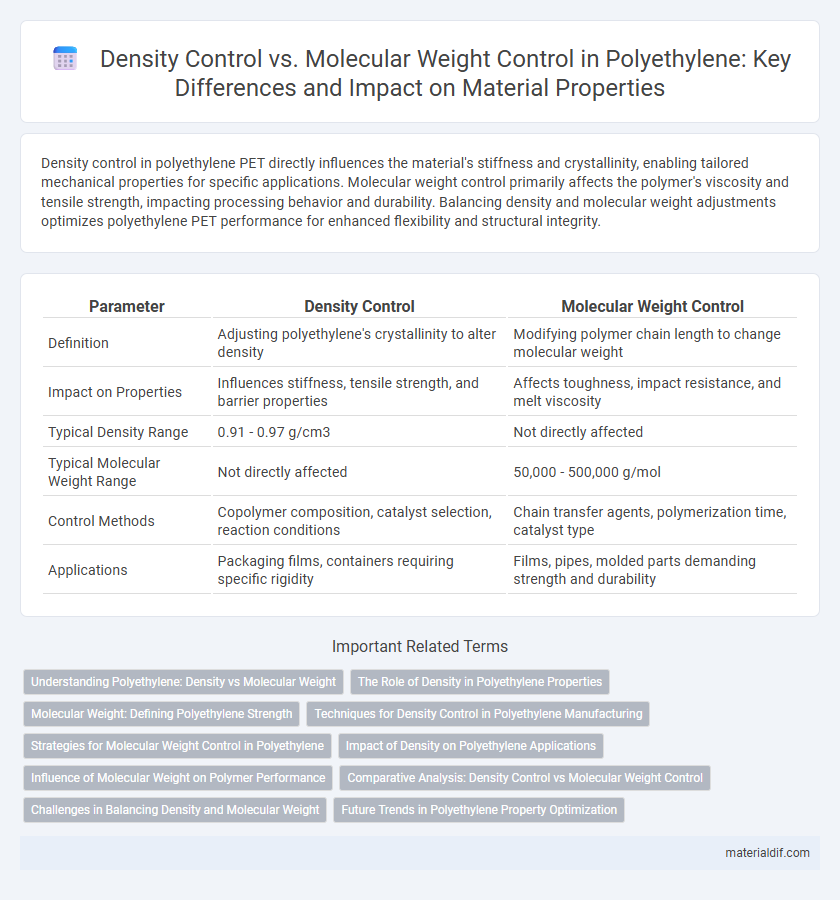

Density control in polyethylene PET directly influences the material's stiffness and crystallinity, enabling tailored mechanical properties for specific applications. Molecular weight control primarily affects the polymer's viscosity and tensile strength, impacting processing behavior and durability. Balancing density and molecular weight adjustments optimizes polyethylene PET performance for enhanced flexibility and structural integrity.

Table of Comparison

| Parameter | Density Control | Molecular Weight Control |

|---|---|---|

| Definition | Adjusting polyethylene's crystallinity to alter density | Modifying polymer chain length to change molecular weight |

| Impact on Properties | Influences stiffness, tensile strength, and barrier properties | Affects toughness, impact resistance, and melt viscosity |

| Typical Density Range | 0.91 - 0.97 g/cm3 | Not directly affected |

| Typical Molecular Weight Range | Not directly affected | 50,000 - 500,000 g/mol |

| Control Methods | Copolymer composition, catalyst selection, reaction conditions | Chain transfer agents, polymerization time, catalyst type |

| Applications | Packaging films, containers requiring specific rigidity | Films, pipes, molded parts demanding strength and durability |

Understanding Polyethylene: Density vs Molecular Weight

Density control in polyethylene primarily influences the polymer's crystallinity and mechanical properties, with lower density materials exhibiting increased branching and flexibility. Molecular weight control affects the polymer's chain length, impacting tensile strength, melt viscosity, and processing characteristics. Understanding the balance between density and molecular weight is essential for tailoring polyethylene grades to specific applications such as packaging, films, or high-strength molded parts.

The Role of Density in Polyethylene Properties

Density in polyethylene significantly influences its mechanical properties, such as stiffness, tensile strength, and impact resistance, by determining the degree of crystallinity within the polymer matrix. Controlling density allows precise tuning of polyethylene grades from low-density (LDPE) with branched chains for flexibility to high-density (HDPE) with linear chains for rigidity, whereas molecular weight primarily affects processability and toughness. Optimizing density rather than molecular weight is critical for applications requiring specific balance between strength and ductility, as density directly impacts polymer chain packing and intermolecular interactions.

Molecular Weight: Defining Polyethylene Strength

Molecular weight significantly influences polyethylene's mechanical strength, as higher molecular weights enhance tensile strength and impact resistance by increasing chain entanglement. Precise control of molecular weight distribution during polymerization enables tailoring of properties such as hardness, flexibility, and durability for specific applications. Unlike density control, which adjusts crystallinity and stiffness, molecular weight control directly impacts the polymer's toughness and elongation characteristics.

Techniques for Density Control in Polyethylene Manufacturing

Density control in polyethylene manufacturing primarily relies on adjusting the comonomer incorporation and polymerization conditions such as temperature and pressure within catalytic processes like Ziegler-Natta or metallocene catalysis. Techniques include modulating the amount and type of alpha-olefin comonomers, which alters short-chain branching and thus density, alongside controlling catalyst activity and polymer chain architecture. Molecular weight control is managed through chain transfer agents or hydrogen addition but influences mechanical properties more than density, separating the two control parameters in process optimization.

Strategies for Molecular Weight Control in Polyethylene

Strategies for molecular weight control in polyethylene involve precise regulation of polymerization conditions such as catalyst type, temperature, and pressure to achieve desired chain lengths. Use of chain transfer agents and comonomers helps tailor molecular weight distribution for specific mechanical properties and processability. Understanding the relationship between molecular weight and density allows optimization of polyethylene for applications ranging from flexible films to high-strength containers.

Impact of Density on Polyethylene Applications

Density significantly influences polyethylene's mechanical properties, with higher density enhancing stiffness, tensile strength, and chemical resistance, making it ideal for packaging and industrial films. Lower density polyethylene offers greater flexibility and impact resistance, suitable for applications like plastic bags and squeeze bottles. Controlling density allows manufacturers to tailor polyethylene grades to specific application requirements, optimizing performance and durability.

Influence of Molecular Weight on Polymer Performance

Molecular weight significantly influences polyethylene performance by affecting its mechanical strength, impact resistance, and processability. Higher molecular weight polymers exhibit enhanced tensile strength and toughness due to longer polymer chains and increased entanglements, while density control primarily adjusts crystallinity and stiffness. Optimizing molecular weight distribution is crucial for tailoring polyethylene properties to specific applications such as packaging films, pipes, and automotive parts.

Comparative Analysis: Density Control vs Molecular Weight Control

Density control in polyethylene manufacturing primarily influences material stiffness, crystallinity, and barrier properties by adjusting chain branching and packing efficiency. Molecular weight control directly impacts mechanical strength, melt viscosity, and processability due to variations in polymer chain length and entanglement. Comparative analysis reveals that optimizing density tailors polyethylene for specific applications requiring defined rigidity and chemical resistance, while molecular weight control fine-tunes toughness and extrusion characteristics for diverse processing methods.

Challenges in Balancing Density and Molecular Weight

Balancing density and molecular weight in polyethylene production poses significant challenges due to their inverse relationship, where increasing density often leads to a decrease in molecular weight and vice versa. Precise control of polymerization catalysts and reaction conditions is essential to optimize both parameters simultaneously, ensuring desirable mechanical properties and processability. Advances in catalyst design aim to overcome this trade-off, enabling improved performance in high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE) variants.

Future Trends in Polyethylene Property Optimization

Future trends in polyethylene property optimization emphasize precise density control to enhance material stiffness and barrier properties, while molecular weight control remains critical for tailoring mechanical strength and processability. Advanced catalyst technologies enable fine-tuning of polymer chain architecture, balancing density and molecular weight for applications demanding specific performance criteria. Emerging methods like metallocene and single-site catalysts facilitate customized polyethylene grades with optimized density-molecular weight distribution for next-generation packaging, automotive, and infrastructure materials.

Density control vs Molecular weight control Infographic

materialdif.com

materialdif.com