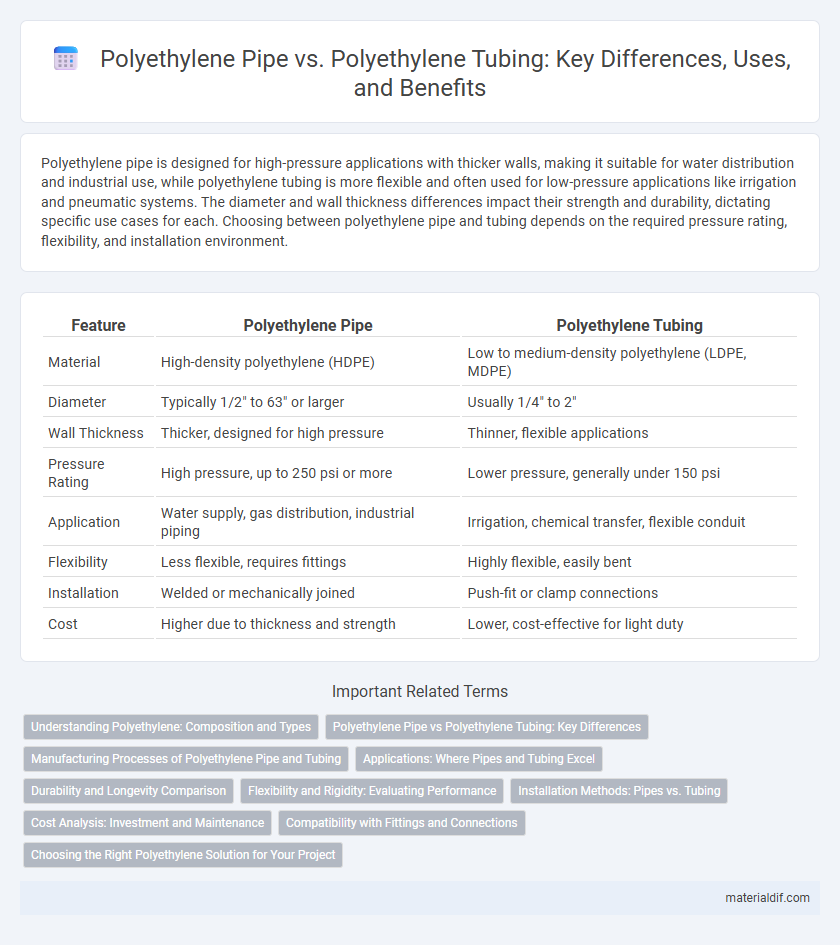

Polyethylene pipe is designed for high-pressure applications with thicker walls, making it suitable for water distribution and industrial use, while polyethylene tubing is more flexible and often used for low-pressure applications like irrigation and pneumatic systems. The diameter and wall thickness differences impact their strength and durability, dictating specific use cases for each. Choosing between polyethylene pipe and tubing depends on the required pressure rating, flexibility, and installation environment.

Table of Comparison

| Feature | Polyethylene Pipe | Polyethylene Tubing |

|---|---|---|

| Material | High-density polyethylene (HDPE) | Low to medium-density polyethylene (LDPE, MDPE) |

| Diameter | Typically 1/2" to 63" or larger | Usually 1/4" to 2" |

| Wall Thickness | Thicker, designed for high pressure | Thinner, flexible applications |

| Pressure Rating | High pressure, up to 250 psi or more | Lower pressure, generally under 150 psi |

| Application | Water supply, gas distribution, industrial piping | Irrigation, chemical transfer, flexible conduit |

| Flexibility | Less flexible, requires fittings | Highly flexible, easily bent |

| Installation | Welded or mechanically joined | Push-fit or clamp connections |

| Cost | Higher due to thickness and strength | Lower, cost-effective for light duty |

Understanding Polyethylene: Composition and Types

Polyethylene pipe and polyethylene tubing are both made from high-density polyethylene (HDPE) but differ in dimensions, flexibility, and application. Polyethylene pipe is typically thicker, rigid, and designed for water, gas, and industrial fluid conveyance, while polyethylene tubing is thinner, more flexible, and used in irrigation, medical, and pneumatic systems. Understanding the variations in molecular weight and density, such as low-density polyethylene (LDPE) versus high-density polyethylene (HDPE), is crucial for selecting the appropriate material based on strength and flexibility requirements.

Polyethylene Pipe vs Polyethylene Tubing: Key Differences

Polyethylene pipe and polyethylene tubing differ primarily in diameter, wall thickness, and applications, with pipes usually designed for higher pressure systems and tubing suited for low-pressure, flexible uses. Polyethylene pipe is commonly used for water, gas, and sewage transport, offering rigid structure and durability, while tubing finds applications in irrigation, medical devices, and fluid transfer due to its flexibility. The selection depends on factors like pressure ratings, installation environment, and mechanical demands, making pipe ideal for infrastructure and tubing for precise, lightweight tasks.

Manufacturing Processes of Polyethylene Pipe and Tubing

Polyethylene pipes are typically manufactured using extrusion processes that involve melting polyethylene resin and shaping it into rigid cylindrical forms, ensuring high density and pressure resistance for applications like water and gas distribution. Polyethylene tubing, produced through similar extrusion methods, is generally made with thinner walls and designed for flexibility, catering to low-pressure uses such as irrigation, medical devices, and cable insulation. The key difference in manufacturing lies in wall thickness control and cooling techniques, directly impacting the structural integrity and intended application of the final product.

Applications: Where Pipes and Tubing Excel

Polyethylene pipes excel in water distribution, gas lines, and industrial fluid transfer due to their high pressure resistance and durability. Polyethylene tubing is preferred for low-pressure applications such as irrigation systems, medical devices, and beverage dispensing, where flexibility and precision are critical. Selecting between polyethylene pipe and tubing depends on factors like pressure requirements, environmental exposure, and installation methods.

Durability and Longevity Comparison

Polyethylene pipe offers superior durability with thicker walls designed to withstand high pressure and external impacts, making it ideal for long-term infrastructure applications. Polyethylene tubing, while flexible and lightweight, typically features thinner walls that are more susceptible to punctures and wear, limiting its lifespan in demanding environments. The enhanced wall thickness and material density of polyethylene pipes contribute significantly to their extended longevity compared to polyethylene tubing.

Flexibility and Rigidity: Evaluating Performance

Polyethylene pipe offers greater rigidity, making it ideal for high-pressure applications such as water mains and gas lines, while polyethylene tubing provides superior flexibility suited for low-pressure uses like irrigation and fluid transfer. The pipe's thicker walls enhance durability and resistance to external forces, whereas the tubing's thinner walls allow easy bending and maneuvering in tight spaces. Selecting between polyethylene pipe and tubing depends on the balance needed between structural strength and adaptable installation requirements.

Installation Methods: Pipes vs. Tubing

Polyethylene pipe installation often requires fusion welding techniques such as butt fusion or electrofusion to create strong, permanent joints, ideal for high-pressure applications. Polyethylene tubing installation typically involves mechanical fittings or compression connectors, allowing for easier assembly and flexibility in low-pressure or residential plumbing systems. The choice between pipe and tubing installation methods depends on the project's pressure requirements, system complexity, and ease of maintenance.

Cost Analysis: Investment and Maintenance

Polyethylene pipe generally requires a higher initial investment compared to polyethylene tubing due to its thicker walls and larger diameter, which provide enhanced durability and pressure resistance. Maintenance costs for polyethylene pipe tend to be lower over time because its robust construction minimizes the risk of leaks and failures in demanding applications. Polyethylene tubing, while cheaper upfront and flexible for low-pressure uses, may incur higher maintenance expenses due to its susceptibility to damage and replacement needs.

Compatibility with Fittings and Connections

Polyethylene pipe and polyethylene tubing differ primarily in wall thickness and flexibility, affecting compatibility with fittings and connections. Polyethylene pipe, being thicker and more rigid, typically requires threaded or compression fittings designed for higher pressure applications, while polyethylene tubing often uses barbed or push-to-connect fittings due to its flexible nature. Ensuring the correct fitting type and size is crucial for creating leak-proof joints in both polyethylene pipe and tubing systems.

Choosing the Right Polyethylene Solution for Your Project

Polyethylene pipe offers durability and high pressure resistance, making it ideal for water supply, gas distribution, and industrial applications, while polyethylene tubing provides flexibility and smaller diameter options suited for irrigation, medical devices, and fluid transfer. Evaluating project requirements like pressure ratings, flexibility needs, and installation environment ensures selection of the appropriate polyethylene product that optimizes performance and longevity. Selecting the right polyethylene solution involves analyzing factors such as pipe diameter, wall thickness, and chemical compatibility to meet specific operational demands effectively.

Polyethylene Pipe vs Polyethylene Tubing Infographic

materialdif.com

materialdif.com