Low-density polyethylene (LDPE) foam offers greater flexibility and cushioning due to its softer, more open-cell structure, making it ideal for packaging and insulation where shock absorption is critical. High-density polyethylene (HDPE) foam provides superior strength and rigidity with a denser, closed-cell composition, suitable for applications requiring durability and resistance to impact. Both materials deliver excellent moisture resistance and thermal insulation, but LDPE is preferred for lightweight, compressible uses, while HDPE excels in structural support and long-term stability.

Table of Comparison

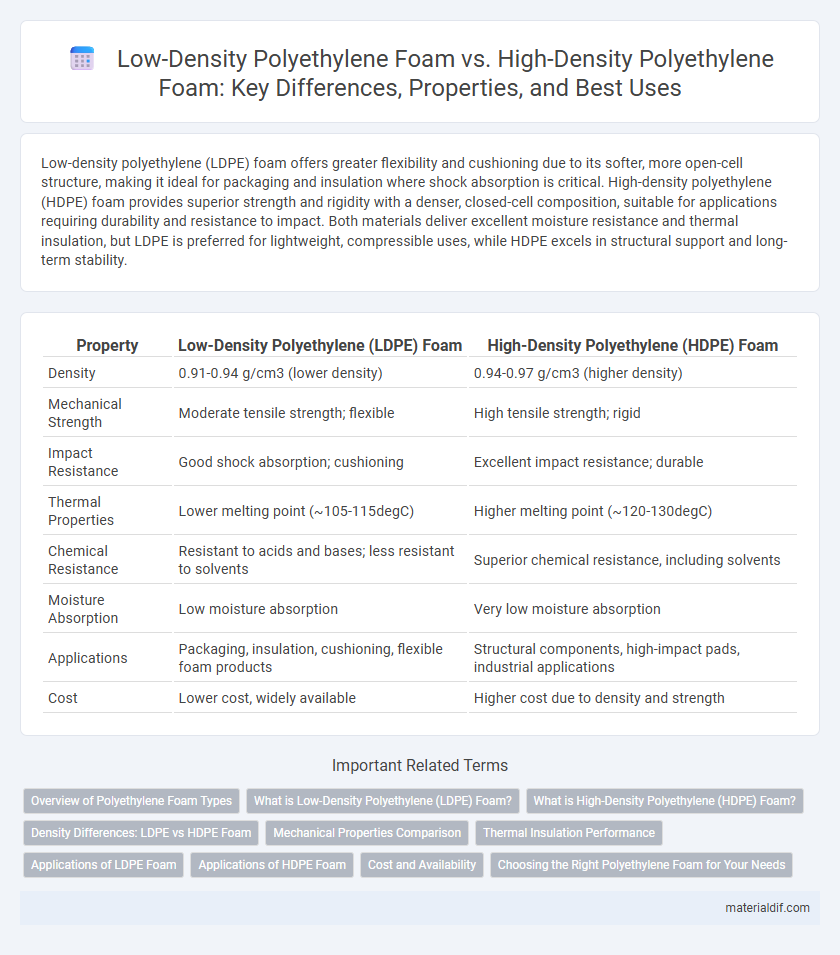

| Property | Low-Density Polyethylene (LDPE) Foam | High-Density Polyethylene (HDPE) Foam |

|---|---|---|

| Density | 0.91-0.94 g/cm3 (lower density) | 0.94-0.97 g/cm3 (higher density) |

| Mechanical Strength | Moderate tensile strength; flexible | High tensile strength; rigid |

| Impact Resistance | Good shock absorption; cushioning | Excellent impact resistance; durable |

| Thermal Properties | Lower melting point (~105-115degC) | Higher melting point (~120-130degC) |

| Chemical Resistance | Resistant to acids and bases; less resistant to solvents | Superior chemical resistance, including solvents |

| Moisture Absorption | Low moisture absorption | Very low moisture absorption |

| Applications | Packaging, insulation, cushioning, flexible foam products | Structural components, high-impact pads, industrial applications |

| Cost | Lower cost, widely available | Higher cost due to density and strength |

Overview of Polyethylene Foam Types

Low-density polyethylene (LDPE) foam features a softer, more flexible texture with excellent cushioning properties, making it ideal for packaging sensitive items and insulation. High-density polyethylene (HDPE) foam offers greater rigidity and impact resistance, often used in applications requiring structural support or heavy-duty protection. Both foam types utilize the versatility of polyethylene, differing primarily in density and resulting mechanical characteristics.

What is Low-Density Polyethylene (LDPE) Foam?

Low-Density Polyethylene (LDPE) foam is a lightweight, flexible material characterized by its low density and closed-cell structure, making it ideal for cushioning, insulation, and packaging applications. Unlike High-Density Polyethylene (HDPE) foam, LDPE foam offers superior shock absorption and softness, resulting from its lower crystallinity and more branched polymer chains. Its excellent chemical resistance, moisture impermeability, and thermal insulation properties contribute to its widespread use in protective packaging, sports equipment padding, and thermal insulation panels.

What is High-Density Polyethylene (HDPE) Foam?

High-Density Polyethylene (HDPE) foam is a durable, rigid material known for its high strength-to-density ratio and excellent chemical resistance, making it suitable for heavy-duty applications compared to Low-Density Polyethylene (LDPE) foam. HDPE foam's closed-cell structure provides superior impact absorption, moisture resistance, and dimensional stability, ideal for industrial uses such as protective packaging, insulation, and flotation devices. Its higher density typically ranges from 0.4 to 0.6 g/cm3, offering enhanced mechanical properties over the softer, more flexible LDPE foam.

Density Differences: LDPE vs HDPE Foam

Low-density polyethylene (LDPE) foam has a density typically ranging from 20 to 80 kg/m3, offering greater flexibility and cushioning due to its open-cell structure. High-density polyethylene (HDPE) foam exhibits densities between 80 and 200 kg/m3, resulting in a more rigid and durable material suited for heavy-duty applications. The contrasting density levels directly influence mechanical properties, thermal insulation, and impact resistance, determining the appropriate foam type for specific industrial uses.

Mechanical Properties Comparison

Low-density polyethylene (LDPE) foam exhibits lower tensile strength and compressive resistance compared to high-density polyethylene (HDPE) foam, making HDPE foam more suitable for applications requiring higher mechanical durability. HDPE foam has greater rigidity, enhanced impact resistance, and superior load-bearing capacity due to its denser molecular structure and higher crystallinity. The mechanical properties of HDPE foam allow for better performance in structural support and protective packaging, whereas LDPE foam offers increased flexibility and cushioning.

Thermal Insulation Performance

Low-density polyethylene (LDPE) foam exhibits superior thermal insulation due to its closed-cell structure and lower density, which traps more air and reduces heat transfer. High-density polyethylene (HDPE) foam, although mechanically stronger, has a higher thermal conductivity because its denser composition facilitates greater heat flow. The choice between LDPE and HDPE foam ultimately depends on balancing insulation requirements with mechanical strength for specific applications.

Applications of LDPE Foam

Low-density polyethylene (LDPE) foam is widely used in packaging, cushioning, and insulation due to its excellent flexibility, shock absorption, and chemical resistance. Its lightweight and closed-cell structure make it ideal for protective padding in electronics, automotive components, and sporting goods. LDPE foam also finds applications in sealing gaskets and vibration dampening materials in various industrial settings.

Applications of HDPE Foam

High-density polyethylene (HDPE) foam is extensively used in industrial and commercial applications due to its superior strength, rigidity, and chemical resistance compared to low-density polyethylene (LDPE) foam. Common applications of HDPE foam include automotive components, marine flotation devices, and protective packaging, where durability and impact resistance are critical. Its ability to withstand harsh environmental conditions makes HDPE foam ideal for construction insulation panels, sport equipment padding, and reusable shipping containers.

Cost and Availability

Low-density polyethylene (LDPE) foam generally costs less and is more widely available due to its simpler manufacturing process and broader application range. High-density polyethylene (HDPE) foam, while offering superior strength and durability, tends to be more expensive and less readily stocked by suppliers. Availability of LDPE foam suits budget-conscious projects, whereas HDPE foam is preferred for specialized uses requiring higher performance despite higher cost.

Choosing the Right Polyethylene Foam for Your Needs

Low-density polyethylene (LDPE) foam offers greater flexibility, cushioning, and shock absorption, making it ideal for packaging fragile items and insulation. High-density polyethylene (HDPE) foam provides superior strength, rigidity, and chemical resistance, perfect for applications requiring durability and structural support. Selecting the right polyethylene foam depends on balancing the need for softness and impact resistance with strength and durability requirements.

Low-density polyethylene foam vs High-density polyethylene foam Infographic

materialdif.com

materialdif.com