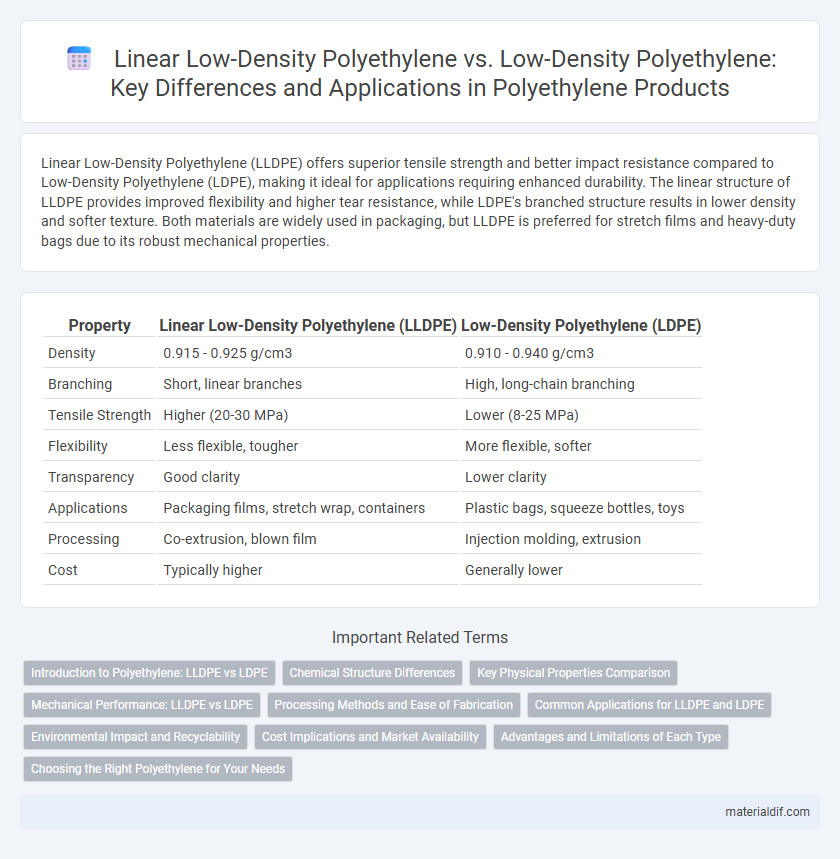

Linear Low-Density Polyethylene (LLDPE) offers superior tensile strength and better impact resistance compared to Low-Density Polyethylene (LDPE), making it ideal for applications requiring enhanced durability. The linear structure of LLDPE provides improved flexibility and higher tear resistance, while LDPE's branched structure results in lower density and softer texture. Both materials are widely used in packaging, but LLDPE is preferred for stretch films and heavy-duty bags due to its robust mechanical properties.

Table of Comparison

| Property | Linear Low-Density Polyethylene (LLDPE) | Low-Density Polyethylene (LDPE) |

|---|---|---|

| Density | 0.915 - 0.925 g/cm3 | 0.910 - 0.940 g/cm3 |

| Branching | Short, linear branches | High, long-chain branching |

| Tensile Strength | Higher (20-30 MPa) | Lower (8-25 MPa) |

| Flexibility | Less flexible, tougher | More flexible, softer |

| Transparency | Good clarity | Lower clarity |

| Applications | Packaging films, stretch wrap, containers | Plastic bags, squeeze bottles, toys |

| Processing | Co-extrusion, blown film | Injection molding, extrusion |

| Cost | Typically higher | Generally lower |

Introduction to Polyethylene: LLDPE vs LDPE

Linear Low-Density Polyethylene (LLDPE) features a linear polymer backbone with significant short-chain branching, resulting in higher tensile strength and flexibility compared to Low-Density Polyethylene (LDPE), which contains more long-chain branching and a less linear structure. LDPE's branched polymer structure contributes to its lower density and greater clarity, making it suitable for applications requiring transparency and flexibility. Both types are thermoplastics derived from ethylene but differ in molecular architecture, influencing their mechanical properties, chemical resistance, and processing methods.

Chemical Structure Differences

Linear Low-Density Polyethylene (LLDPE) features a linear polymer chain with significant short-chain branching, enhancing its tensile strength and flexibility. In contrast, Low-Density Polyethylene (LDPE) has extensive long-chain and short-chain branching, resulting in a more amorphous and less dense structure. These chemical structure differences influence their mechanical properties and suitability for applications such as packaging films and containers.

Key Physical Properties Comparison

Linear Low-Density Polyethylene (LLDPE) exhibits higher tensile strength and greater impact resistance compared to Low-Density Polyethylene (LDPE), due to its linear polymer chains with short branches. LDPE has a lower density, increased flexibility, and better clarity, attributed to its highly branched structure, which reduces crystallinity. Both materials differ in melting points, with LLDPE typically melting around 120-125degC and LDPE melting between 105-115degC, affecting their thermal performance in applications.

Mechanical Performance: LLDPE vs LDPE

Linear Low-Density Polyethylene (LLDPE) exhibits higher tensile strength and superior impact resistance compared to Low-Density Polyethylene (LDPE), making it more suitable for applications requiring durability under stress. LLDPE features a more uniform linear structure with short-chain branching, contributing to enhanced mechanical properties such as increased puncture resistance and better elongation at break. LDPE, with its highly branched structure, offers greater flexibility but lower mechanical strength and stiffness relative to LLDPE, limiting its use in high-stress environments.

Processing Methods and Ease of Fabrication

Linear Low-Density Polyethylene (LLDPE) is typically processed using extrusion and film blowing techniques due to its branched but linear polymer structure, offering improved tensile strength and puncture resistance compared to Low-Density Polyethylene (LDPE). LDPE, characterized by its highly branched polymer chains, is easier to fabricate through conventional methods such as injection molding and blow molding because of its lower melting point and greater flowability. The choice between LLDPE and LDPE in manufacturing depends largely on the desired mechanical properties and processing requirements, with LLDPE favoring applications needing higher durability and LDPE suited for items requiring simpler fabrication.

Common Applications for LLDPE and LDPE

Linear Low-Density Polyethylene (LLDPE) finds extensive use in stretch films, agricultural mulch films, and flexible packaging due to its high tensile strength and puncture resistance. Low-Density Polyethylene (LDPE) is commonly used in plastic bags, containers, and dispensing bottles, valued for its flexibility and clarity. Both polymers serve crucial roles in packaging industries but differ in mechanical properties tailored for specific applications.

Environmental Impact and Recyclability

Linear Low-Density Polyethylene (LLDPE) offers improved mechanical properties over Low-Density Polyethylene (LDPE), which can enhance the durability and lifespan of products, potentially reducing environmental waste. Both LLDPE and LDPE are recyclable, but LLDPE's higher tensile strength allows it to be reused in applications requiring more robust materials, promoting effective recycling streams. LDPE typically exhibits lower melting points, making it easier to recycle in certain processes, though its environmental impact is heightened by broader usage in single-use plastic films and packaging.

Cost Implications and Market Availability

Linear Low-Density Polyethylene (LLDPE) typically commands a higher price than Low-Density Polyethylene (LDPE) due to its advanced tensile strength and flexibility, making it suitable for heavy-duty packaging applications. Market availability for LLDPE is steadily increasing as demand rises in sectors like agriculture and consumer goods, while LDPE remains widely accessible thanks to its longstanding use in film and bag production. Cost implications favor LDPE for budget-conscious projects, though LLDPE's superior properties justify the premium in high-performance uses.

Advantages and Limitations of Each Type

Linear Low-Density Polyethylene (LLDPE) offers superior tensile strength, puncture resistance, and flexibility compared to Low-Density Polyethylene (LDPE), making it ideal for stretch films and packaging requiring durability. LDPE provides excellent clarity, ease of processing, and good impact resistance but has lower tensile strength and puncture resistance relative to LLDPE, limiting its use in high-stress applications. LLDPE's narrower molecular weight distribution enhances mechanical properties while LDPE's branched structure contributes to its softness and transparency.

Choosing the Right Polyethylene for Your Needs

Linear Low-Density Polyethylene (LLDPE) offers higher tensile strength and better puncture resistance compared to Low-Density Polyethylene (LDPE), making it ideal for heavy-duty packaging and flexible films. LDPE provides excellent flexibility, clarity, and ease of sealing, suitable for applications like plastic bags and food wrap where softness and transparency are crucial. Selecting the right polyethylene depends on factors such as mechanical strength requirements, flexibility, and environmental stress resistance in your specific application.

Linear Low-Density Polyethylene vs Low-Density Polyethylene Infographic

materialdif.com

materialdif.com