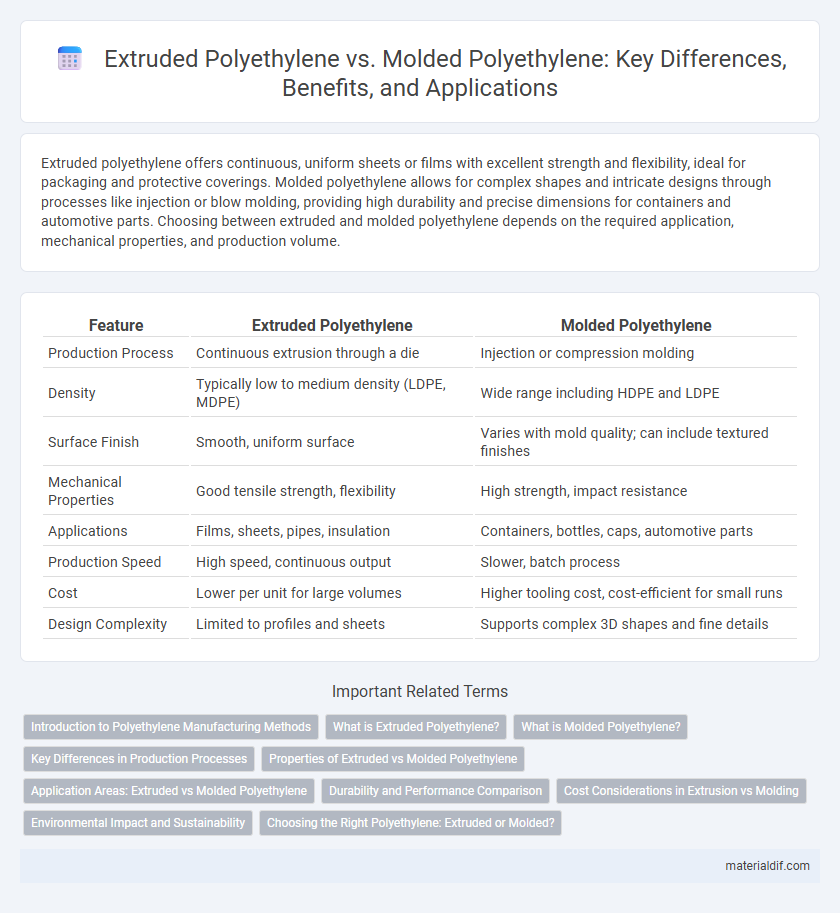

Extruded polyethylene offers continuous, uniform sheets or films with excellent strength and flexibility, ideal for packaging and protective coverings. Molded polyethylene allows for complex shapes and intricate designs through processes like injection or blow molding, providing high durability and precise dimensions for containers and automotive parts. Choosing between extruded and molded polyethylene depends on the required application, mechanical properties, and production volume.

Table of Comparison

| Feature | Extruded Polyethylene | Molded Polyethylene |

|---|---|---|

| Production Process | Continuous extrusion through a die | Injection or compression molding |

| Density | Typically low to medium density (LDPE, MDPE) | Wide range including HDPE and LDPE |

| Surface Finish | Smooth, uniform surface | Varies with mold quality; can include textured finishes |

| Mechanical Properties | Good tensile strength, flexibility | High strength, impact resistance |

| Applications | Films, sheets, pipes, insulation | Containers, bottles, caps, automotive parts |

| Production Speed | High speed, continuous output | Slower, batch process |

| Cost | Lower per unit for large volumes | Higher tooling cost, cost-efficient for small runs |

| Design Complexity | Limited to profiles and sheets | Supports complex 3D shapes and fine details |

Introduction to Polyethylene Manufacturing Methods

Extruded polyethylene is produced by forcing melted resin through a shaped die, resulting in continuous profiles like pipes, sheets, or films characterized by uniform thickness and strength. Molded polyethylene involves injecting or compressing molten resin into molds, enabling the creation of complex shapes with precise dimensions and varied densities. These manufacturing methods influence the physical properties and applications of polyethylene, with extrusion favored for long, uniform products and molding suited for intricate, high-tolerance items.

What is Extruded Polyethylene?

Extruded polyethylene is a polymer formed by melting raw polyethylene pellets and forcing the molten material through a shaped die to create continuous profiles such as sheets, tubes, or films. This process produces uniform thickness and smooth surfaces ideal for packaging, piping, and insulation applications. Extruded polyethylene typically features enhanced mechanical properties and consistent density compared to molded polyethylene, which is created by injecting or compressing the material into molds.

What is Molded Polyethylene?

Molded polyethylene is produced by heating polyethylene pellets until molten and then injecting or compressing the material into a mold cavity to achieve a specific shape, allowing for complex and precise geometries. This process results in parts with excellent strength, durability, and resistance to impact, making molded polyethylene ideal for automotive components, containers, and industrial applications. It differs from extruded polyethylene, which is formed by pushing melted material through a die to create continuous shapes like sheets or tubes.

Key Differences in Production Processes

Extruded polyethylene is produced by melting raw polyethylene pellets and forcing the molten material through a die to create continuous shapes like films, sheets, or pipes, ensuring uniform thickness and smooth surfaces. Molded polyethylene involves heating the polymer and injecting or compressing it into molds, allowing for complex shapes and varying wall thicknesses ideal for containers and intricate designs. The extrusion method supports high-volume production of consistent cross-sectional profiles, whereas molding provides versatility in forming detailed three-dimensional products.

Properties of Extruded vs Molded Polyethylene

Extruded polyethylene typically exhibits a uniform density and enhanced tensile strength due to continuous heating and shaping, resulting in superior flexibility and impact resistance compared to molded polyethylene. Molded polyethylene offers higher dimensional stability and better surface finish, with the ability to produce complex shapes, but may have lower tensile strength and slight inconsistencies in density. The choice between extruded and molded polyethylene depends on application-specific requirements such as mechanical performance, surface characteristics, and production volume.

Application Areas: Extruded vs Molded Polyethylene

Extruded polyethylene is commonly used in applications such as tubing, pipes, and protective films due to its continuous production process that yields uniform thickness and strength. Molded polyethylene, produced through processes like injection or rotational molding, is ideal for manufacturing complex shapes such as containers, automotive parts, and industrial tanks. The choice between extruded and molded polyethylene depends on the required product geometry, mechanical properties, and application environment.

Durability and Performance Comparison

Extruded polyethylene offers superior impact resistance and uniform density, making it ideal for applications requiring consistent mechanical strength and durability. Molded polyethylene, produced through high-pressure molding, provides enhanced structural integrity and is well-suited for complex shapes and thicker walls. Both methods yield durable polyethylene products, but extrusion excels in producing lightweight, flexible sheets while molding offers better performance in heavy-duty, load-bearing scenarios.

Cost Considerations in Extrusion vs Molding

Extruded polyethylene typically offers lower production costs due to continuous processing and reduced material waste compared to molded polyethylene, which involves higher initial tooling expenses and longer cycle times. Extrusion is ideal for high-volume runs of uniform cross-section products, lowering per-unit costs significantly. Molded polyethylene incurs increased costs with complex shapes and detailed finishes, but allows greater design flexibility and precision for intricate parts.

Environmental Impact and Sustainability

Extruded polyethylene typically consumes less energy during production compared to molded polyethylene, resulting in a lower carbon footprint. Molded polyethylene often involves more material waste due to trimming and excess flash, whereas extrusion processes are more efficient with raw material usage. Both types are recyclable, but extruded forms are generally easier to recycle due to their uniform shape and density, enhancing sustainability efforts.

Choosing the Right Polyethylene: Extruded or Molded?

Choosing between extruded and molded polyethylene requires understanding their distinct production processes and applications. Extruded polyethylene, created by continuously pushing the molten polymer through a die, offers uniform thickness and is ideal for films, sheets, and tubing with high tensile strength. Molded polyethylene, formed by injecting or compressing molten polymer into molds, provides complex shapes and enhanced impact resistance, making it suitable for containers, automotive parts, and custom components.

Extruded Polyethylene vs Molded Polyethylene Infographic

materialdif.com

materialdif.com