Copolymer polyethylene offers enhanced flexibility and impact resistance compared to homopolymer polyethylene, making it suitable for applications requiring durability and toughness. Homopolymer polyethylene has a higher density and crystallinity, resulting in greater tensile strength and stiffness, ideal for rigid packaging and containers. The choice between copolymer and homopolymer polyethylene depends on the balance of mechanical properties needed for specific industrial uses.

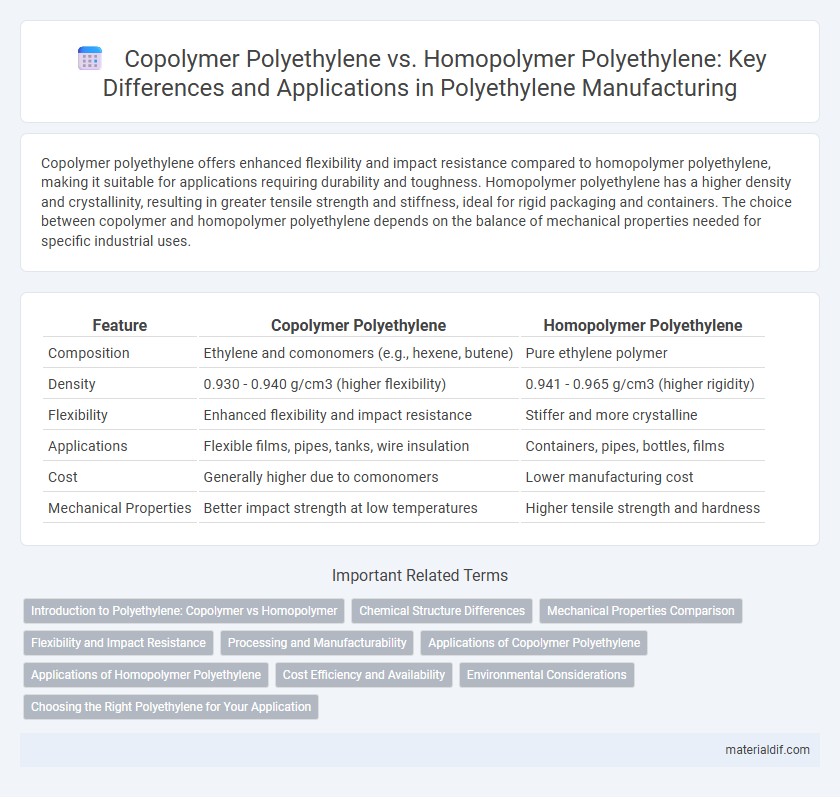

Table of Comparison

| Feature | Copolymer Polyethylene | Homopolymer Polyethylene |

|---|---|---|

| Composition | Ethylene and comonomers (e.g., hexene, butene) | Pure ethylene polymer |

| Density | 0.930 - 0.940 g/cm3 (higher flexibility) | 0.941 - 0.965 g/cm3 (higher rigidity) |

| Flexibility | Enhanced flexibility and impact resistance | Stiffer and more crystalline |

| Applications | Flexible films, pipes, tanks, wire insulation | Containers, pipes, bottles, films |

| Cost | Generally higher due to comonomers | Lower manufacturing cost |

| Mechanical Properties | Better impact strength at low temperatures | Higher tensile strength and hardness |

Introduction to Polyethylene: Copolymer vs Homopolymer

Copolymer polyethylene consists of two or more monomers polymerized together, resulting in enhanced impact resistance and flexibility compared to homopolymer polyethylene, which is made from a single type of monomer, usually ethylene, offering higher density and tensile strength. Copolymer variants include linear low-density polyethylene (LLDPE) and ethylene-vinyl acetate (EVA), commonly used in packaging films and flexible containers. Homopolymer polyethylene, classified as high-density polyethylene (HDPE), is widely applied in rigid containers, pipes, and plastic bottles due to its superior rigidity and chemical resistance.

Chemical Structure Differences

Copolymer polyethylene consists of two or more different monomers, typically ethylene combined with other alpha-olefins like butene or hexene, leading to a branched chemical structure with unique properties such as increased flexibility and impact resistance. Homopolymer polyethylene is made from a single type of monomer, ethylene, resulting in a more linear molecular structure that provides higher crystallinity, density, and tensile strength. The variation in molecular architecture between copolymer and homopolymer polyethylene directly influences their thermal stability, mechanical performance, and suitability for different industrial applications.

Mechanical Properties Comparison

Copolymer polyethylene exhibits enhanced impact resistance and flexibility due to the incorporation of comonomers, which disrupt crystallinity and improve toughness compared to homopolymer polyethylene that has higher tensile strength and stiffness from its linear structure. Homopolymer polyethylene typically offers superior hardness and chemical resistance, making it suitable for rigid applications, while copolymer variants excel in low-temperature performance and elongation. The molecular architecture of copolymers allows for better stress distribution under load, resulting in improved durability in dynamic and cyclic mechanical environments.

Flexibility and Impact Resistance

Copolymer polyethylene exhibits enhanced flexibility and superior impact resistance compared to homopolymer polyethylene due to the incorporation of comonomers like butene or hexene, which disrupt the polymer chain regularity. The branched structure in copolymer polyethylene reduces crystallinity, resulting in improved toughness and better performance under mechanical stress. Homopolymer polyethylene, with its higher density and crystallinity, offers greater stiffness but lower flexibility and impact resistance, making it less suitable for applications requiring durability and flexibility.

Processing and Manufacturability

Copolymer polyethylene, produced by incorporating alpha-olefins, offers improved flexibility and impact resistance, facilitating easier processing in applications requiring enhanced toughness and clarity. Homopolymer polyethylene, consisting solely of ethylene units, exhibits higher crystallinity and density, resulting in superior rigidity and tensile strength but may require higher temperatures and pressures during manufacturing. The choice between copolymer and homopolymer polyethylene significantly affects extrusion, molding efficiency, and final product properties in industrial processing.

Applications of Copolymer Polyethylene

Copolymer polyethylene exhibits enhanced flexibility and impact resistance compared to homopolymer polyethylene, making it ideal for applications such as packaging films, plastic bags, and tubing. Its improved clarity and toughness suit it for use in healthcare products like medical tubing and flexible containers. The material's superior stress-crack resistance supports its use in industrial liners and heavy-duty materials.

Applications of Homopolymer Polyethylene

Homopolymer polyethylene, known for its high density and crystalline structure, is extensively used in applications requiring strong tensile strength and durability, such as plastic bags, bottles, and piping. Its excellent chemical resistance and stiffness make it ideal for manufacturing containers for household chemicals, grocery bags, and geomembranes. Compared to copolymer polyethylene, homopolymer variants are preferred in packaging and industrial uses where rigidity and moisture barrier properties are critical.

Cost Efficiency and Availability

Copolymer polyethylene offers enhanced flexibility and impact resistance compared to homopolymer polyethylene, making it suitable for specialized applications, though it generally comes at a higher cost. Homopolymer polyethylene is more cost-efficient and widely available due to its simpler production process and higher demand in packaging and containers. Manufacturers often choose homopolymer polyethylene when prioritizing budget and large-scale availability, while copolymer variants are preferred for performance-critical uses despite increased expenses.

Environmental Considerations

Copolymer polyethylene, composed of ethylene and other monomers, generally offers enhanced flexibility and impact resistance compared to homopolymer polyethylene, which consists solely of ethylene units. From an environmental perspective, homopolymer polyethylene tends to have a simpler molecular structure, potentially enabling more straightforward recycling processes. However, copolymer grades may provide improved durability, extending product lifespan and reducing waste generation during use.

Choosing the Right Polyethylene for Your Application

Copolymer polyethylene offers enhanced flexibility and impact resistance due to the incorporation of comonomers, making it ideal for applications requiring toughness and clarity such as tubing and packaging films. Homopolymer polyethylene provides higher tensile strength and stiffness, suitable for rigid containers and heavy-duty parts where durability is crucial. Selecting the right polyethylene depends on balancing mechanical properties, chemical resistance, and end-use environmental conditions for optimized performance.

Copolymer Polyethylene vs Homopolymer Polyethylene Infographic

materialdif.com

materialdif.com