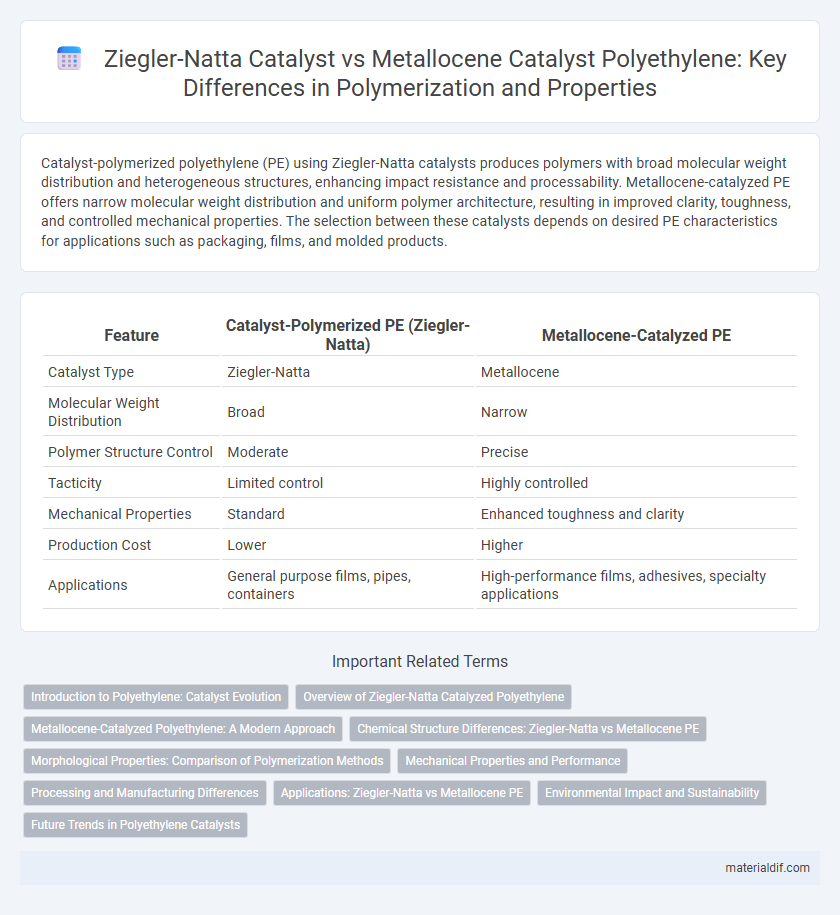

Catalyst-polymerized polyethylene (PE) using Ziegler-Natta catalysts produces polymers with broad molecular weight distribution and heterogeneous structures, enhancing impact resistance and processability. Metallocene-catalyzed PE offers narrow molecular weight distribution and uniform polymer architecture, resulting in improved clarity, toughness, and controlled mechanical properties. The selection between these catalysts depends on desired PE characteristics for applications such as packaging, films, and molded products.

Table of Comparison

| Feature | Catalyst-Polymerized PE (Ziegler-Natta) | Metallocene-Catalyzed PE |

|---|---|---|

| Catalyst Type | Ziegler-Natta | Metallocene |

| Molecular Weight Distribution | Broad | Narrow |

| Polymer Structure Control | Moderate | Precise |

| Tacticity | Limited control | Highly controlled |

| Mechanical Properties | Standard | Enhanced toughness and clarity |

| Production Cost | Lower | Higher |

| Applications | General purpose films, pipes, containers | High-performance films, adhesives, specialty applications |

Introduction to Polyethylene: Catalyst Evolution

Catalyst-polymerized polyethylene, pioneered through Ziegler-Natta catalysts, revolutionized PE production by enabling controlled polymerization of ethylene into high-density and linear low-density polyethylene variants. Metallocene-catalyzed polyethylene introduced a new era of precision catalysis, offering enhanced molecular weight distribution control and uniform polymer architecture compared to traditional Ziegler-Natta systems. These catalyst evolutions have critically influenced polyethylene's mechanical properties, crystallinity, and processing behavior in diverse industrial applications.

Overview of Ziegler-Natta Catalyzed Polyethylene

Ziegler-Natta catalyzed polyethylene is produced using heterogeneous catalysts composed of transition metals such as titanium or vanadium combined with aluminum alkyl co-catalysts, enabling high stereoregularity and molecular weight control. This catalyst system is widely utilized for manufacturing linear low-density polyethylene (LLDPE) and high-density polyethylene (HDPE) with broad molecular weight distribution and varying crystallinity levels. Compared to metallocene-catalyzed polyethylene, Ziegler-Natta catalysts offer cost efficiency and scalability but exhibit less precise control over polymer microstructure and narrower molecular weight distribution.

Metallocene-Catalyzed Polyethylene: A Modern Approach

Metallocene-catalyzed polyethylene represents a modern approach to polymer production, offering superior control over polymer architecture compared to traditional Ziegler-Natta catalysts. This catalyst system enables precise tuning of molecular weight distribution, comonomer incorporation, and polymer microstructure, resulting in enhanced mechanical properties and processability. Metallocene catalysts facilitate the production of bimodal and multimodal polyethylene grades with tailored density and crystallinity, expanding applications in high-performance packaging and automotive components.

Chemical Structure Differences: Ziegler-Natta vs Metallocene PE

Ziegler-Natta catalyst-polymerized polyethylene exhibits a broader molecular weight distribution and more heterogeneous branching due to multiple active sites, resulting in polymers with varied chain lengths and irregular side chains. In contrast, metallocene-catalyzed polyethylene features a uniform molecular architecture with narrow molecular weight distribution and precise control over branching patterns, attributed to single-site catalyst behavior. These chemical structure differences significantly influence the physical properties, crystallinity, and mechanical performance of the resulting polyethylene materials.

Morphological Properties: Comparison of Polymerization Methods

Catalyst-polymerized polyethylene using Ziegler-Natta catalysts typically exhibits a heterogeneous morphology with broader molecular weight distribution and varied crystallinity, resulting in distinct spherulitic structures. Metallocene-catalyzed polyethylene offers a more uniform molecular architecture with narrow molecular weight distribution and controlled comonomer incorporation, producing consistent lamellar thickness and enhanced mechanical properties. This precise control in metallocene polymerization enables tailored morphological features that improve polymer performance in applications requiring high clarity and toughness.

Mechanical Properties and Performance

Catalyst-polymerized polyethylene (PE) using Ziegler-Natta catalysts typically exhibits higher molecular weight distribution and broader polymer chain branching, resulting in enhanced toughness and impact resistance. Metallocene-catalyzed PE offers superior molecular uniformity and narrow molecular weight distribution, leading to improved tensile strength, stiffness, and optical clarity. Mechanical properties of metallocene PE are more consistent and customizable, making it ideal for high-performance applications requiring precise material specifications.

Processing and Manufacturing Differences

Catalyst-polymerized polyethylene using Ziegler-Natta catalysts typically exhibits a broader molecular weight distribution, resulting in higher processability for applications requiring robustness and flexibility in manufacturing. Metallocene-catalyzed polyethylene offers narrow molecular weight distribution and uniform polymer chain structure, enabling precise control over polymer morphology and enhanced mechanical properties, ideal for advanced extrusion and molding techniques. The manufacturing process with metallocene catalysts involves more stringent temperature and pressure controls to maintain consistent polymerization, contrasting with the relatively tolerant conditions of Ziegler-Natta catalyst systems.

Applications: Ziegler-Natta vs Metallocene PE

Ziegler-Natta catalyst-polymerized polyethylene is widely used in applications requiring high mechanical strength and cost-efficiency, such as packaging films, pipes, and containers. Metallocene-catalyzed polyethylene delivers superior clarity, uniformity, and enhanced barrier properties, making it ideal for precision applications like medical tubing, high-performance films, and specialty adhesives. Differences in polymer microstructure and molecular weight distribution drive the selection between Ziegler-Natta and metallocene PE to match specific application demands.

Environmental Impact and Sustainability

Catalyst-polymerized polyethylene (Ziegler-Natta) typically involves heterogeneous catalysts that can generate more waste and require higher energy input, leading to a larger environmental footprint compared to metallocene-catalyzed PE. Metallocene catalysts enable precise control over polymer architecture, resulting in materials with improved recyclability and enhanced mechanical properties, which contribute to sustainability by extending product life cycles. The enhanced catalyst efficiency and lower production temperatures in metallocene processes reduce greenhouse gas emissions and resource consumption, aligning better with sustainable manufacturing goals.

Future Trends in Polyethylene Catalysts

Future trends in polyethylene catalysts emphasize enhancing catalyst efficiency and polymer property control, with metallocene catalysts gaining prominence for their uniform active sites and precise molecular weight distribution. Ziegler-Natta catalysts continue evolving through advanced ligand designs to improve stereoregularity and reduce production costs. Innovations in single-site catalyst technology and combinatorial catalyst screening are driving the development of polyethylene with tailor-made properties for applications in packaging, films, and high-performance materials.

Catalyst-polymerized PE (Ziegler-Natta) vs Metallocene-catalyzed PE Infographic

materialdif.com

materialdif.com