Black polyethylene offers enhanced UV resistance and durability, making it ideal for outdoor applications compared to natural polyethylene, which typically has a translucent appearance. Natural polyethylene provides greater clarity and is preferred for packaging where product visibility is crucial. Both types maintain excellent chemical resistance and flexibility, but their color differences directly influence application suitability and aesthetic preferences.

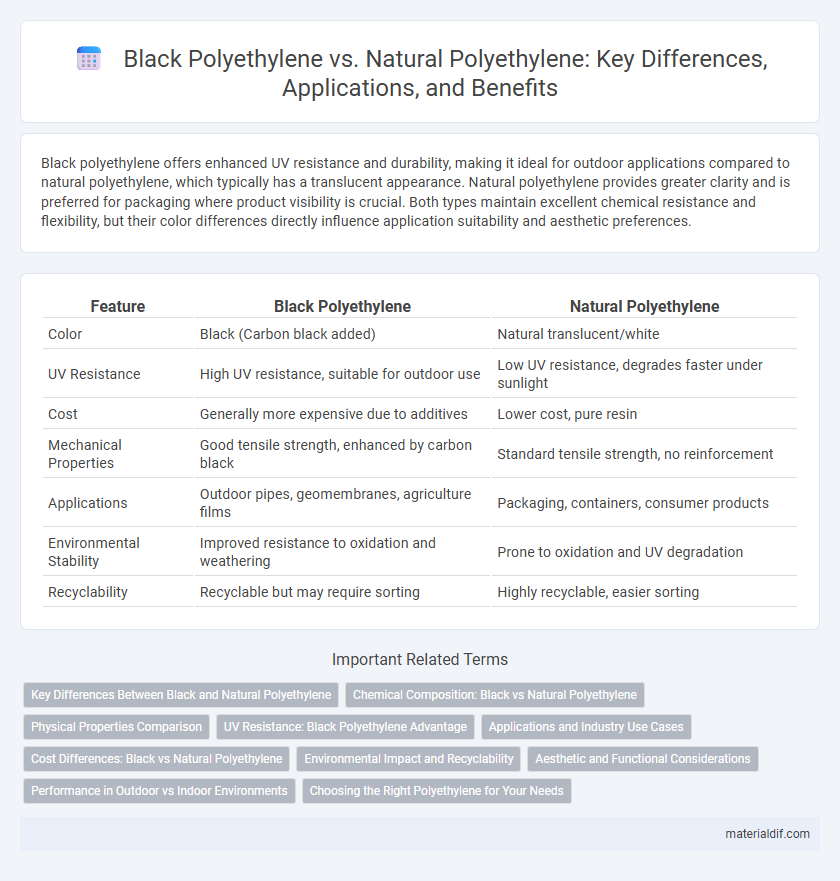

Table of Comparison

| Feature | Black Polyethylene | Natural Polyethylene |

|---|---|---|

| Color | Black (Carbon black added) | Natural translucent/white |

| UV Resistance | High UV resistance, suitable for outdoor use | Low UV resistance, degrades faster under sunlight |

| Cost | Generally more expensive due to additives | Lower cost, pure resin |

| Mechanical Properties | Good tensile strength, enhanced by carbon black | Standard tensile strength, no reinforcement |

| Applications | Outdoor pipes, geomembranes, agriculture films | Packaging, containers, consumer products |

| Environmental Stability | Improved resistance to oxidation and weathering | Prone to oxidation and UV degradation |

| Recyclability | Recyclable but may require sorting | Highly recyclable, easier sorting |

Key Differences Between Black and Natural Polyethylene

Black polyethylene contains carbon black additives that enhance UV resistance and durability, making it ideal for outdoor applications, while natural polyethylene is more translucent and lacks UV stabilizers. The inclusion of carbon black also improves black polyethylene's thermal conductivity and lifespan, whereas natural polyethylene is often preferred for food packaging due to its purity and clarity. Production cost differences arise because black polyethylene requires additional additives, influencing its application in industrial versus consumer products.

Chemical Composition: Black vs Natural Polyethylene

Black polyethylene contains carbon black additives that enhance UV resistance and durability, while natural polyethylene remains colorless and transparent due to the absence of such fillers. The chemical backbone of both black and natural polyethylene is primarily composed of repeating ethylene monomers (C2H4)n, ensuring similar fundamental polymer properties. Differences in chemical composition arise from additives in black polyethylene that improve performance but do not alter the basic polyethylene polymer chain.

Physical Properties Comparison

Black polyethylene exhibits enhanced UV resistance due to the presence of carbon black, which significantly improves durability under sunlight exposure compared to natural polyethylene. The density of both black and natural polyethylene ranges between 0.91 to 0.96 g/cm3, with minimal variation in tensile strength and flexibility. Natural polyethylene, however, tends to have slightly higher clarity and lower heat resistance, making black polyethylene more suitable for outdoor and high-stress applications.

UV Resistance: Black Polyethylene Advantage

Black polyethylene contains carbon black particles that significantly enhance its UV resistance by absorbing and dissipating ultraviolet radiation, preventing polymer degradation. Natural polyethylene lacks these additives, making it prone to faster deterioration when exposed to sunlight and outdoor conditions. This UV stabilization in black polyethylene extends its lifespan and maintains mechanical strength in applications such as agricultural films, piping, and outdoor containers.

Applications and Industry Use Cases

Black polyethylene, enriched with carbon black, offers enhanced UV resistance and durability, making it ideal for outdoor applications such as agricultural films, geomembranes, and construction materials. Natural polyethylene provides greater clarity and is preferred in packaging, medical devices, and food storage due to its non-opaque properties. Both variants serve diverse industries, with black polyethylene dominating heavy-duty, protective environments while natural polyethylene is favored for consumer goods requiring transparency and flexibility.

Cost Differences: Black vs Natural Polyethylene

Black polyethylene typically costs less than natural polyethylene due to the incorporation of carbon black, which not only acts as a pigment but also enhances UV resistance and durability, reducing long-term material degradation. Natural polyethylene, being uncolored and used in applications requiring clarity or food contact compliance, often entails stricter processing standards that increase its production cost. The price difference can range from 10% to 30%, influenced by factors such as raw material sourcing, grade specifications, and intended application performance.

Environmental Impact and Recyclability

Black polyethylene contains carbon black additives that hinder its detectability in near-infrared (NIR) recycling systems, leading to lower recycling rates and increased environmental waste. Natural polyethylene, lacking colorants, is more easily identified and sorted in recycling facilities, promoting higher recyclability and reduced landfill accumulation. The production and disposal of black polyethylene contribute more significantly to environmental pollution due to limited recycling and longer degradation times compared to natural polyethylene.

Aesthetic and Functional Considerations

Black polyethylene offers superior UV resistance and durability due to the addition of carbon black, enhancing its functional lifespan for outdoor applications. Natural polyethylene features a translucent appearance, allowing for aesthetic versatility but lower protection against UV degradation. Both materials provide excellent chemical resistance and flexibility, with the choice largely depending on the balance between visual requirements and environmental exposure.

Performance in Outdoor vs Indoor Environments

Black polyethylene exhibits superior UV resistance due to carbon black additives, making it ideal for prolonged outdoor use by preventing degradation from sunlight exposure. Natural polyethylene lacks these UV stabilizers, resulting in faster deterioration and brittleness when exposed to outdoor elements, limiting its outdoor performance. Indoors, both black and natural polyethylene perform similarly with high chemical resistance and durability, but black polyethylene's UV properties offer minimal benefits without sunlight exposure.

Choosing the Right Polyethylene for Your Needs

Black polyethylene offers superior UV resistance due to its carbon black content, making it ideal for outdoor applications and long-term durability. Natural polyethylene, being translucent and without additives, provides excellent clarity and chemical resistance, suitable for packaging and food-grade products. Selecting between black and natural polyethylene depends on exposure conditions, required strength, and application-specific performance criteria.

Black Polyethylene vs Natural Polyethylene Infographic

materialdif.com

materialdif.com