Linear polyethylene features a straight, unbranched polymer chain, offering higher density, greater tensile strength, and better chemical resistance compared to branched polyethylene. Branched polyethylene contains side chains that prevent tight packing, resulting in lower density and increased flexibility, making it suitable for applications like film and packaging. Understanding the differences between linear and branched polyethylene is essential for selecting the right material based on mechanical properties and application requirements.

Table of Comparison

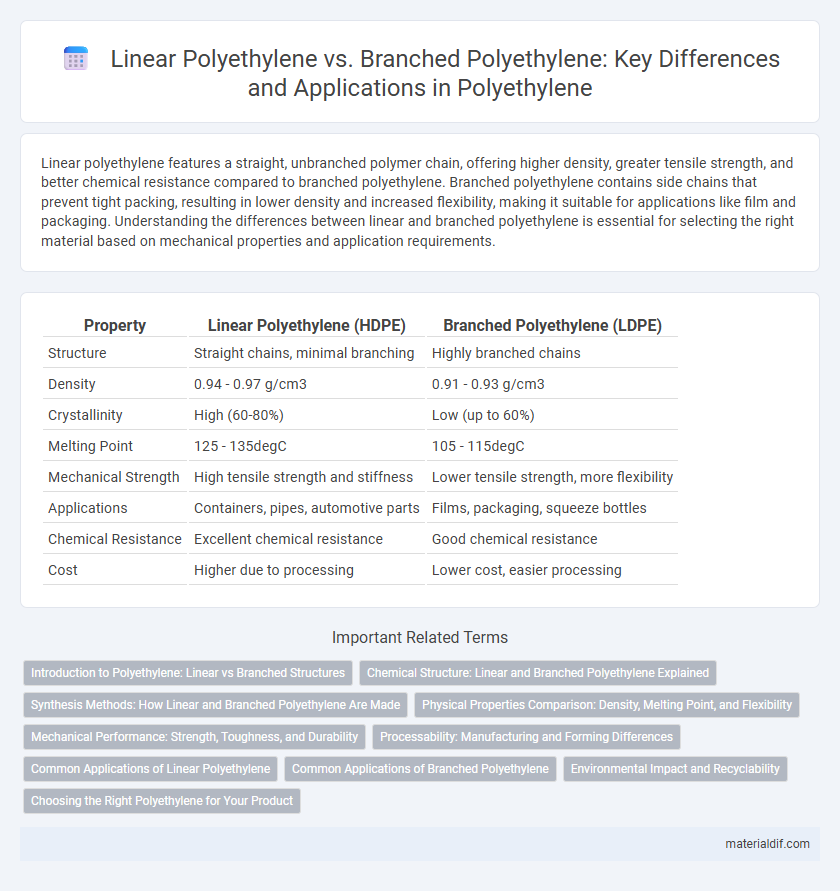

| Property | Linear Polyethylene (HDPE) | Branched Polyethylene (LDPE) |

|---|---|---|

| Structure | Straight chains, minimal branching | Highly branched chains |

| Density | 0.94 - 0.97 g/cm3 | 0.91 - 0.93 g/cm3 |

| Crystallinity | High (60-80%) | Low (up to 60%) |

| Melting Point | 125 - 135degC | 105 - 115degC |

| Mechanical Strength | High tensile strength and stiffness | Lower tensile strength, more flexibility |

| Applications | Containers, pipes, automotive parts | Films, packaging, squeeze bottles |

| Chemical Resistance | Excellent chemical resistance | Good chemical resistance |

| Cost | Higher due to processing | Lower cost, easier processing |

Introduction to Polyethylene: Linear vs Branched Structures

Linear polyethylene consists of long, unbranched polymer chains that result in higher density and crystallinity, making it stronger and more rigid. Branched polyethylene contains side chains that hinder tight packing of molecules, leading to lower density, increased flexibility, and impact resistance. These structural differences influence applications, with linear polyethylene commonly used in high-strength products and branched polyethylene favored for film and packaging materials.

Chemical Structure: Linear and Branched Polyethylene Explained

Linear polyethylene consists of long, unbranched chains of ethylene monomers, resulting in a high density and crystallinity due to tight molecular packing. Branched polyethylene has side chains attached to the main polymer backbone, which reduces crystallinity and density, enhancing flexibility and impact resistance. These structural differences significantly influence the mechanical properties and applications of each type.

Synthesis Methods: How Linear and Branched Polyethylene Are Made

Linear polyethylene is primarily produced through coordination polymerization using catalysts like Ziegler-Natta or metallocene, which promote the growth of polymer chains with minimal branching. Branched polyethylene is synthesized via free radical polymerization or by introducing branching agents during polymerization, resulting in a polymer structure with short or long chain branches. The choice of catalyst and polymerization technique directly influences the density, crystallinity, and mechanical properties of the final polyethylene product.

Physical Properties Comparison: Density, Melting Point, and Flexibility

Linear polyethylene exhibits higher density, typically around 0.94 to 0.97 g/cm3, compared to branched polyethylene, which ranges from 0.91 to 0.93 g/cm3 due to its low-density structure. The melting point of linear polyethylene is generally higher, approximately 130 to 135degC, whereas branched polyethylene melts at lower temperatures near 105 to 115degC, reflecting its less crystalline nature. In terms of flexibility, branched polyethylene demonstrates greater flexibility and impact resistance, attributable to its amorphous regions created by branching, while linear polyethylene tends to be more rigid and strong.

Mechanical Performance: Strength, Toughness, and Durability

Linear polyethylene exhibits higher tensile strength and improved toughness due to its closely packed molecular chains, resulting in enhanced durability under mechanical stress. Branched polyethylene, with its irregular chain structure, offers greater flexibility but lower strength and impact resistance compared to its linear counterpart. The mechanical performance differences make linear polyethylene ideal for applications demanding high strength and longevity, while branched polyethylene suits products requiring enhanced elasticity and shock absorption.

Processability: Manufacturing and Forming Differences

Linear polyethylene exhibits higher density and crystallinity, resulting in enhanced tensile strength and better chemical resistance, which facilitates more precise manufacturing processes such as injection molding and film extrusion. Branched polyethylene, characterized by its lower density and amorphous structure, offers superior flexibility and easier melting points, allowing for simpler thermoplastic forming methods like blow molding and rotational molding. These structural differences directly impact processing temperatures, flow properties, and final product performance in industrial applications.

Common Applications of Linear Polyethylene

Linear polyethylene, primarily high-density polyethylene (HDPE), is widely used in packaging, such as containers, bottles, and plastic bags due to its strength and chemical resistance. It also finds applications in piping systems, geomembranes, and automotive fuel tanks, where durability and impact resistance are crucial. This material's linear molecular structure enables higher tensile strength compared to branched polyethylene, making it ideal for products requiring rigidity and toughness.

Common Applications of Branched Polyethylene

Branched polyethylene, particularly low-density polyethylene (LDPE), is widely used in packaging films, plastic bags, and flexible containers due to its enhanced flexibility and toughness. Its branched molecular structure provides superior impact resistance and clarity, making it ideal for squeeze bottles and lids. This type of polyethylene is also utilized in wire and cable insulation, where durability and elasticity are critical.

Environmental Impact and Recyclability

Linear polyethylene, such as High-Density Polyethylene (HDPE), has a more compact molecular structure, resulting in higher density and greater recyclability due to its uniformity, which allows for easier processing and less contamination in recycling streams. Branched polyethylene, including Low-Density Polyethylene (LDPE), features side chains that create a less dense, more flexible material but complicate recycling efforts because of the varied molecular weight and lower melting points, often leading to downcycling or limited reuse. The environmental impact of linear polyethylene is generally lower because efficient recycling reduces landfill waste and resource consumption, whereas branched polyethylene's limited recyclability contributes to higher environmental footprints through increased plastic pollution and energy-intensive disposal methods.

Choosing the Right Polyethylene for Your Product

Linear polyethylene (HDPE) offers higher tensile strength, better chemical resistance, and greater rigidity, making it ideal for products requiring durability and structural integrity such as piping, containers, and automotive parts. Branched polyethylene (LDPE) provides enhanced flexibility, impact resistance, and transparency, suitable for applications like plastic bags, film wraps, and squeeze bottles. Selecting the right polyethylene depends on balancing mechanical properties, processing methods, and end-use requirements to optimize performance and cost-efficiency.

Linear Polyethylene vs Branched Polyethylene Infographic

materialdif.com

materialdif.com