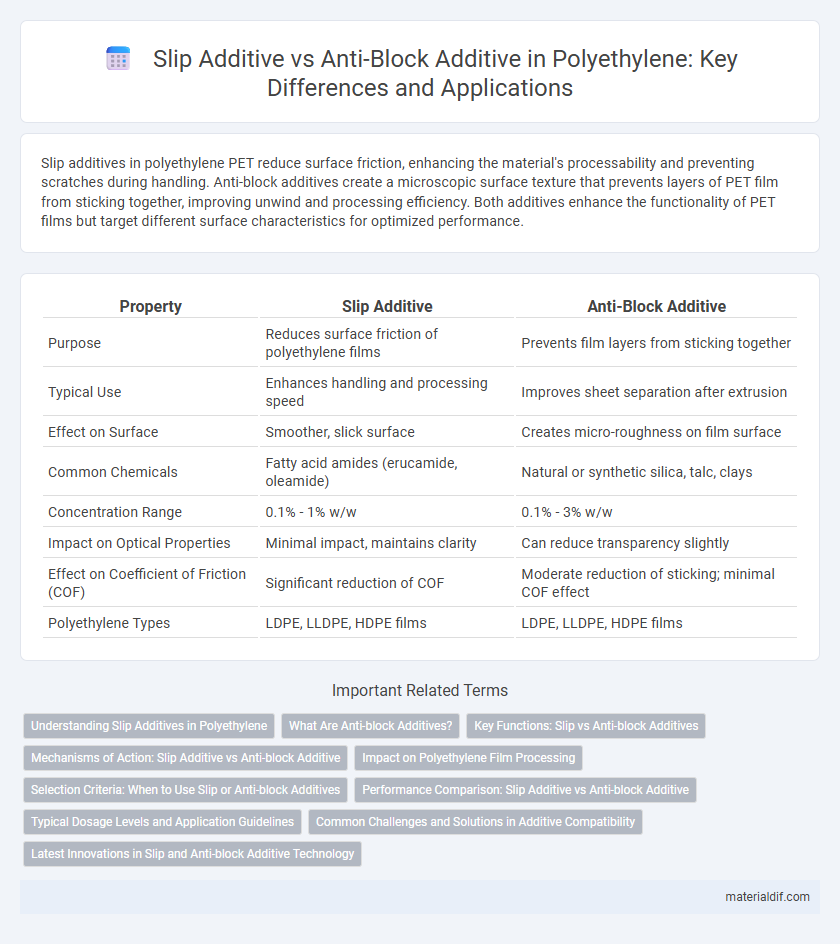

Slip additives in polyethylene PET reduce surface friction, enhancing the material's processability and preventing scratches during handling. Anti-block additives create a microscopic surface texture that prevents layers of PET film from sticking together, improving unwind and processing efficiency. Both additives enhance the functionality of PET films but target different surface characteristics for optimized performance.

Table of Comparison

| Property | Slip Additive | Anti-Block Additive |

|---|---|---|

| Purpose | Reduces surface friction of polyethylene films | Prevents film layers from sticking together |

| Typical Use | Enhances handling and processing speed | Improves sheet separation after extrusion |

| Effect on Surface | Smoother, slick surface | Creates micro-roughness on film surface |

| Common Chemicals | Fatty acid amides (erucamide, oleamide) | Natural or synthetic silica, talc, clays |

| Concentration Range | 0.1% - 1% w/w | 0.1% - 3% w/w |

| Impact on Optical Properties | Minimal impact, maintains clarity | Can reduce transparency slightly |

| Effect on Coefficient of Friction (COF) | Significant reduction of COF | Moderate reduction of sticking; minimal COF effect |

| Polyethylene Types | LDPE, LLDPE, HDPE films | LDPE, LLDPE, HDPE films |

Understanding Slip Additives in Polyethylene

Slip additives in polyethylene reduce surface friction, allowing smoother processing and improved handling by preventing the film from sticking to machinery or itself. These additives migrate to the surface, creating a lubricating layer that enhances flexibility and ease of use without altering the polymer's strength. Unlike anti-block additives, which are designed to prevent films from sticking together through microscopic surface roughening, slip additives specifically target friction reduction for optimized manufacturing efficiency and product performance.

What Are Anti-block Additives?

Anti-block additives are specialized compounds incorporated into polyethylene films to prevent the layers from sticking together during processing and storage, ensuring smooth handling and separation. These additives create a microscopic roughness on the film surface, reducing intermolecular forces and blocking phenomena without compromising clarity or mechanical properties. Common anti-block agents include silica, talc, and calcium carbonate, which enhance the film's slip characteristics and improve overall manufacturing efficiency.

Key Functions: Slip vs Anti-block Additives

Slip additives in polyethylene reduce surface friction, enhancing material flow and processing efficiency, while anti-block additives prevent layers of polyethylene film from sticking together, improving handling and clarity. Slip additives typically consist of fatty acid amides which migrate to the surface to create a lubricating layer, whereas anti-block additives often include silica or talc particles that create microscopic roughness. Effective use of these additives ensures optimal film performance, balancing smoothness and anti-block properties for packaging and industrial applications.

Mechanisms of Action: Slip Additive vs Anti-block Additive

Slip additives in polyethylene reduce surface friction by migrating to the polymer surface, forming a lubricating layer that facilitates easier material handling and processing. Anti-block additives create microscopic surface irregularities that prevent sticking between polymer layers by increasing surface roughness and reducing contact area. Both additives enhance polyethylene performance, but slip additives focus on friction reduction, while anti-block additives primarily inhibit layer adhesion.

Impact on Polyethylene Film Processing

Slip additives reduce friction between polyethylene film surfaces, enhancing unwind speed and preventing sticking during processing, which improves production efficiency. Anti-block additives create micro-roughness on the film surface, preventing layers from adhering and easing film separation without compromising clarity. The combined application of slip and anti-block additives optimizes polyethylene film handling, reduces defects, and ensures consistent output in film extrusion and converting operations.

Selection Criteria: When to Use Slip or Anti-block Additives

Slip additives are selected for polyethylene films requiring reduced surface friction to enhance processing speed and prevent film blocking during unwinding, ideal for packaging applications with high-speed machinery. Anti-block additives are preferred when clear polyethylene films need to maintain optical clarity and prevent adhesion between film layers without significantly altering surface texture. Selection depends on the balance between desired surface slip properties and anti-block performance, considering factors such as film application, processing conditions, and end-use requirements.

Performance Comparison: Slip Additive vs Anti-block Additive

Slip additives significantly reduce surface friction in polyethylene films, enhancing processing speed and film handling by minimizing static and tackiness. Anti-block additives improve film clarity and prevent layers from sticking together by creating micro-roughness between surfaces, which is critical for high-quality packaging applications. While slip additives optimize mechanical performance and ease of use during manufacturing, anti-block additives primarily enhance product functionality and film separation without compromising transparency.

Typical Dosage Levels and Application Guidelines

Slip additives in polyethylene are typically used at dosage levels ranging from 0.1% to 0.5% by weight to enhance surface slip and reduce friction, ideal for film and packaging applications. Anti-block additives are generally added at 0.05% to 0.3% to prevent film layers from sticking together, improving processing and handling in extrusion and film production. Proper dosage depends on polymer type, processing conditions, and desired surface properties to balance slip performance and anti-block efficacy.

Common Challenges and Solutions in Additive Compatibility

Slip additives and anti-block additives in polyethylene often present challenges due to their differing chemical properties, which can lead to incompatibility issues such as uneven dispersion and compromised film clarity. Common solutions include selecting additives with compatible polarities and incorporating processing aids like dispersing agents to enhance uniform distribution within the polymer matrix. Optimizing additive concentration and employing advanced compounding techniques significantly improve the balance between slip performance and anti-block efficiency, ensuring high-quality polyethylene films.

Latest Innovations in Slip and Anti-block Additive Technology

Recent advancements in slip and anti-block additives for polyethylene have enhanced surface lubrication and reduced film sticking without compromising clarity or mechanical properties. Novel nano-coated additives demonstrate superior migration control, providing longer-lasting slip performance while maintaining anti-block efficiency. These innovations contribute to improved processing speeds and packaging aesthetics, fulfilling industry demands for high-performance polyethylene films.

Slip additive vs Anti-block additive Infographic

materialdif.com

materialdif.com