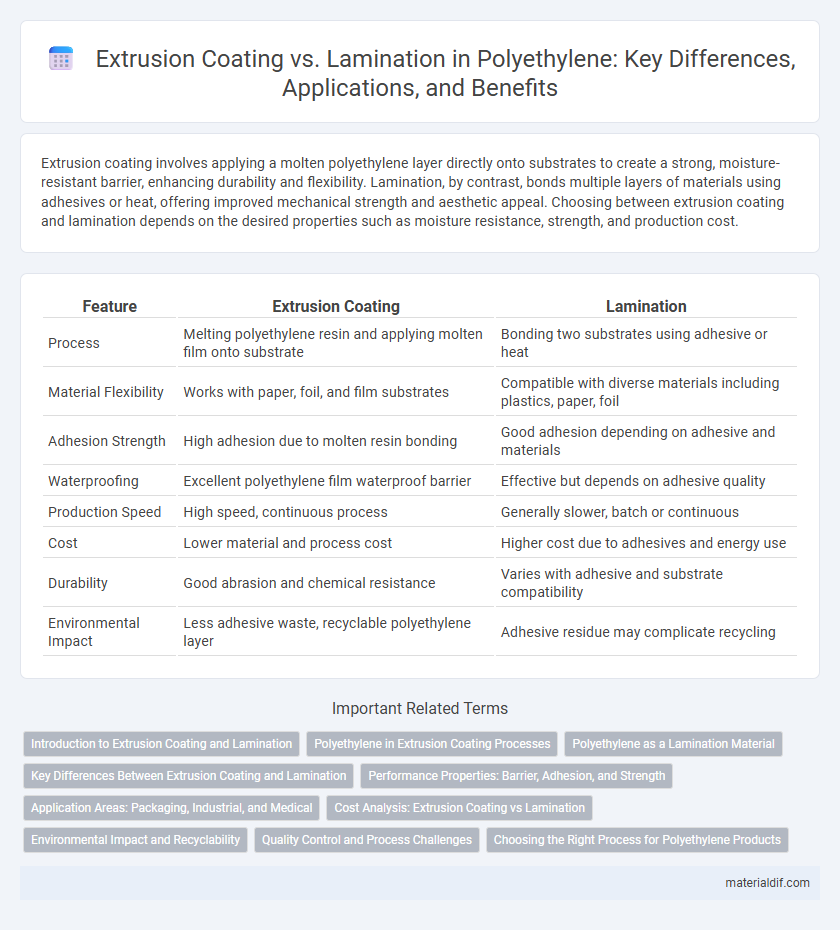

Extrusion coating involves applying a molten polyethylene layer directly onto substrates to create a strong, moisture-resistant barrier, enhancing durability and flexibility. Lamination, by contrast, bonds multiple layers of materials using adhesives or heat, offering improved mechanical strength and aesthetic appeal. Choosing between extrusion coating and lamination depends on the desired properties such as moisture resistance, strength, and production cost.

Table of Comparison

| Feature | Extrusion Coating | Lamination |

|---|---|---|

| Process | Melting polyethylene resin and applying molten film onto substrate | Bonding two substrates using adhesive or heat |

| Material Flexibility | Works with paper, foil, and film substrates | Compatible with diverse materials including plastics, paper, foil |

| Adhesion Strength | High adhesion due to molten resin bonding | Good adhesion depending on adhesive and materials |

| Waterproofing | Excellent polyethylene film waterproof barrier | Effective but depends on adhesive quality |

| Production Speed | High speed, continuous process | Generally slower, batch or continuous |

| Cost | Lower material and process cost | Higher cost due to adhesives and energy use |

| Durability | Good abrasion and chemical resistance | Varies with adhesive and substrate compatibility |

| Environmental Impact | Less adhesive waste, recyclable polyethylene layer | Adhesive residue may complicate recycling |

Introduction to Extrusion Coating and Lamination

Extrusion coating involves applying a molten polyethylene layer directly onto a substrate, creating a strong, waterproof barrier ideal for packaging and industrial applications. Lamination combines two or more layers of materials, often bonded with adhesives or heat, to enhance strength, durability, and aesthetic qualities in films and flexible packaging. Both processes improve the protective and functional properties of polyethylene-based products, but differ in their bonding methods and material combinations.

Polyethylene in Extrusion Coating Processes

Extrusion coating with polyethylene involves melting the polymer and applying it directly onto substrates like paper, cardboard, or foil to create a moisture-resistant and flexible barrier. This process enables strong adhesion and excellent sealing properties, especially for packaging applications requiring durability and high-quality finish. Compared to lamination, extrusion coating with polyethylene offers faster processing times and fewer material compatibility issues, making it a preferred method for cost-effective, high-performance protective layers.

Polyethylene as a Lamination Material

Polyethylene excels as a lamination material due to its excellent moisture barrier properties, flexibility, and chemical resistance, making it ideal for packaging applications requiring durability and protection. Compared to extrusion coating, lamination with polyethylene offers enhanced multi-layer composite structures by bonding different substrates together, thereby improving mechanical strength and thermal stability. Its ability to create strong, uniform films enhances product shelf life and resistance to environmental factors, positioning polyethylene lamination as a superior choice in industrial and food packaging solutions.

Key Differences Between Extrusion Coating and Lamination

Extrusion coating applies molten polyethylene directly onto a substrate, creating a strong, uniform bond that enhances moisture resistance and mechanical strength, while lamination involves bonding multiple layers of materials using adhesives, providing greater flexibility in material combinations and improved barrier properties. Extrusion coating typically offers faster production speeds and higher durability under stress, whereas lamination allows for more customized finishes and graphic effects on packaging. The choice between extrusion coating and lamination depends on factors like product protection requirements, cost efficiency, and desired aesthetic outcomes.

Performance Properties: Barrier, Adhesion, and Strength

Extrusion coating of polyethylene offers superior adhesion to substrates and excellent moisture barrier properties due to the molten polymer's direct bonding, enhancing package integrity. Lamination provides enhanced barrier performance against gases and aromas by combining multiple layers, but adhesion depends heavily on adhesive tie layers and may exhibit weaker bond strength under stress. Strength in extrusion coating typically comes from the polyethylene's polymer matrix, whereas lamination strength derives from the combined mechanical properties of laminated films, ideal for tailored barrier and performance requirements.

Application Areas: Packaging, Industrial, and Medical

Extrusion coating of polyethylene is widely used in packaging for applications requiring moisture barriers and heat-sealable surfaces, such as food and beverage cartons, while lamination excels in industrial settings where multi-layer strength and chemical resistance are critical, including flexible packaging and protective films. In medical applications, polyethylene lamination offers superior sterilization compatibility and breathable barriers essential for surgical wraps and medical packaging. Both processes enhance polyethylene's protective properties but are selected based on specific functional demands within each sector.

Cost Analysis: Extrusion Coating vs Lamination

Extrusion coating typically offers lower initial equipment costs and faster production speeds compared to lamination, making it more cost-effective for high-volume polyethylene applications. Lamination involves higher material and processing expenses due to the use of adhesives and multi-layer films, but provides enhanced barrier properties and durability. Cost analysis favors extrusion coating for economies of scale, while lamination suits specialty applications where performance justifies the premium.

Environmental Impact and Recyclability

Extrusion coating with polyethylene uses fewer materials and generates less waste compared to lamination, enhancing environmental sustainability. Lamination often combines multiple layers of incompatible materials, complicating recycling processes and reducing recyclability. The single-material nature of extrusion-coated polyethylene facilitates easier recycling and decreases environmental footprint.

Quality Control and Process Challenges

Extrusion coating of polyethylene ensures a uniform, strong bond to substrates through precise temperature and pressure control, reducing defects like delamination or bubbles. Lamination offers multi-layer protection but demands exact adhesive selection and curing parameters to maintain clarity and adhesion without compromising flexibility. Both processes face challenges in monitoring thickness consistency, surface contamination, and ensuring adhesion strength under variable production speeds, requiring advanced quality control techniques like inline sensors and real-time analytics.

Choosing the Right Process for Polyethylene Products

Extrusion coating offers superior adhesion and moisture resistance for polyethylene products, ideal for packaging requiring durability and barrier properties. Lamination provides enhanced printability and aesthetic appeal by bonding polyethylene film with other substrates, suitable for multilayer packaging applications. Selecting the right process depends on product requirements such as flexibility, protection level, and cost-efficiency in production.

Extrusion Coating vs Lamination Infographic

materialdif.com

materialdif.com