Low-Density Polyethylene (LDPE) foam offers excellent flexibility and cushioning, making it ideal for protective packaging and insulation applications. Expanded Polyethylene (EPE) foam provides superior shock absorption and resilience due to its closed-cell structure, commonly used in impact protection and sports equipment. Both foams deliver lightweight durability, but LDPE foam excels in compressibility while EPE foam stands out for higher elasticity and repeated-use strength.

Table of Comparison

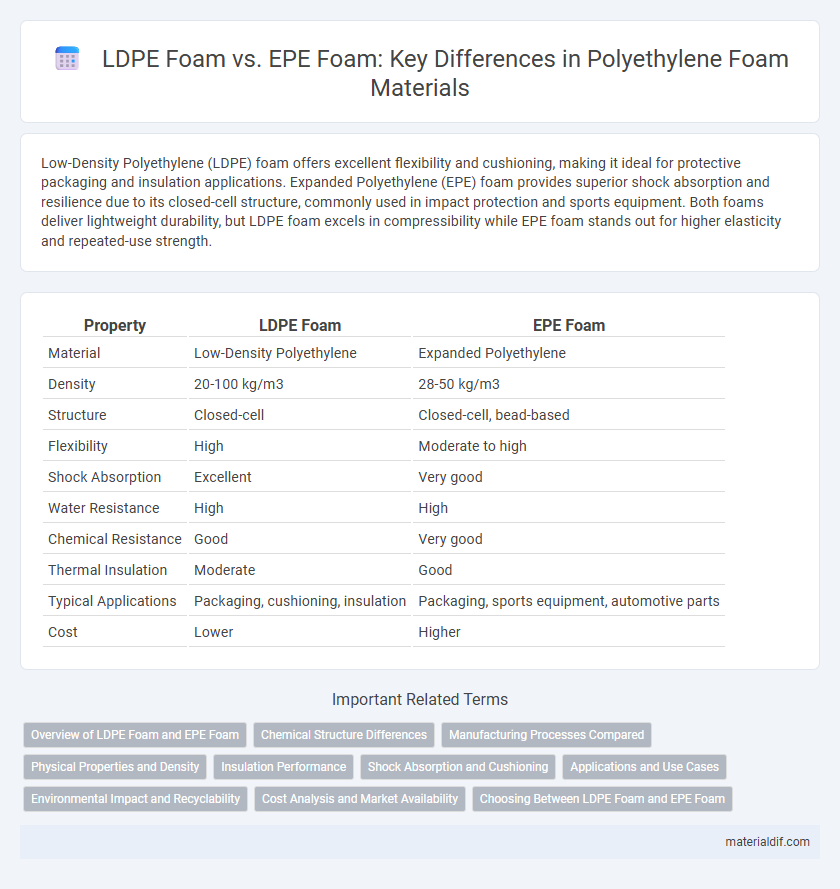

| Property | LDPE Foam | EPE Foam |

|---|---|---|

| Material | Low-Density Polyethylene | Expanded Polyethylene |

| Density | 20-100 kg/m3 | 28-50 kg/m3 |

| Structure | Closed-cell | Closed-cell, bead-based |

| Flexibility | High | Moderate to high |

| Shock Absorption | Excellent | Very good |

| Water Resistance | High | High |

| Chemical Resistance | Good | Very good |

| Thermal Insulation | Moderate | Good |

| Typical Applications | Packaging, cushioning, insulation | Packaging, sports equipment, automotive parts |

| Cost | Lower | Higher |

Overview of LDPE Foam and EPE Foam

Low-Density Polyethylene (LDPE) Foam features a soft, flexible structure with closed-cell composition, commonly used for packaging, cushioning, and insulation due to its excellent impact resistance and moisture barrier properties. Expanded Polyethylene (EPE) Foam consists of expanded beads fused into a lightweight, resilient material offering superior shock absorption and thermal insulation, ideal for protective packaging and construction applications. Both foams are chemically inert, resistant to chemicals and water, but EPE Foam typically provides enhanced cushioning and durability compared to LDPE Foam.

Chemical Structure Differences

Low-Density Polyethylene (LDPE) foam is characterized by a highly branched polymer chain structure, resulting in lower density and increased flexibility. Expanded Polyethylene (EPE) foam consists of a linear polyethylene polymer with minimal branching, providing greater rigidity and impact resistance. The chemical structure difference between LDPE and EPE directly influences their respective mechanical properties and applications in packaging and insulation.

Manufacturing Processes Compared

Low-Density Polyethylene (LDPE) foam is produced through a chemical blowing agent method, where gas is generated within the polymer matrix during extrusion, creating a closed-cell structure with fine, uniform bubbles. Expanded Polyethylene (EPE) foam manufacturing involves the expansion of pre-formed polyethylene beads in a steam chamber, causing the beads to soften and fuse together into an open or semi-open cellular structure. These differing manufacturing processes influence the density, cushioning properties, and moisture resistance of the resulting foam materials.

Physical Properties and Density

Low-Density Polyethylene (LDPE) foam is characterized by a softer texture, higher flexibility, and a typical density range of 15-40 kg/m3, making it ideal for cushioning applications requiring shock absorption. Expanded Polyethylene (EPE) foam exhibits a more rigid structure, better resilience, and density values often between 25-90 kg/m3, which provide enhanced impact resistance and structural support. Both foams offer excellent moisture resistance and thermal insulation, but EPE's higher density improves load-bearing capabilities compared to LDPE's lightweight softness.

Insulation Performance

Low-Density Polyethylene (LDPE) foam offers excellent thermal insulation due to its closed-cell structure, effectively minimizing heat transfer and moisture absorption. Expanded Polyethylene (EPE) foam, with its bead-foam composition, provides superior cushioning but has higher thermal conductivity, resulting in moderate insulation performance compared to LDPE. Both materials are lightweight and resistant to chemicals, but LDPE foam is preferred for applications requiring enhanced thermal insulation.

Shock Absorption and Cushioning

Low-Density Polyethylene (LDPE) foam exhibits superior shock absorption due to its closed-cell structure, which effectively dissipates impact energy and prevents compression set. Expanded Polyethylene (EPE) foam offers excellent cushioning with a bead-based, open-cell construction, providing flexibility and lightweight support that molds to shapes under pressure. Both foams excel in protective packaging, but LDPE is preferred for high-impact resistance while EPE is favored for versatile cushioning and repetitive use.

Applications and Use Cases

Low-Density Polyethylene (LDPE) foam is widely used in packaging, cushioning fragile items, and thermal insulation due to its flexibility, softness, and resistance to moisture. Expanded Polyethylene (EPE) foam, known for its higher density and superior impact absorption, is commonly utilized in automotive components, sports equipment, and protective padding. Both foams serve critical roles in shock absorption and lightweight protection across industrial and consumer applications, with LDPE preferred for delicate product packaging and EPE chosen for durability and structural support.

Environmental Impact and Recyclability

Low-Density Polyethylene (LDPE) foam and Expanded Polyethylene (EPE) foam both originate from polyethylene but differ in their environmental impact and recyclability. LDPE foam, being less dense and more flexible, tends to degrade faster under environmental conditions and is widely accepted in recycling programs due to its simpler chemical structure. EPE foam, characterized by its closed-cell structure and higher resilience, offers excellent cushioning but presents challenges in recycling because of its complex matrix and limited acceptance in municipal recycling systems.

Cost Analysis and Market Availability

Low-Density Polyethylene (LDPE) foam typically incurs higher production costs due to its denser molecular structure and more energy-intensive manufacturing process compared to Expanded Polyethylene (EPE) foam. Market availability of LDPE foam is generally more limited, with higher demand in specialized industries such as packaging and cushioning, whereas EPE foam enjoys broader distribution channels and lower retail prices driven by widespread use in consumer goods. Cost analysis favors EPE foam in large-scale applications due to its cost-effectiveness and easier scalability, while LDPE foam commands premium pricing aligned with superior durability and impact resistance.

Choosing Between LDPE Foam and EPE Foam

Low-Density Polyethylene (LDPE) foam offers superior flexibility and cushioning, ideal for delicate packaging and protective applications requiring shock absorption. Expanded Polyethylene (EPE) foam provides enhanced rigidity and resilience, making it better suited for heavy-duty packaging and insulation purposes. Selecting between LDPE and EPE foam depends on the required balance of softness, durability, and impact resistance for specific industrial or commercial uses.

Low-Density Polyethylene (LDPE) Foam vs Expanded Polyethylene (EPE) Foam Infographic

materialdif.com

materialdif.com