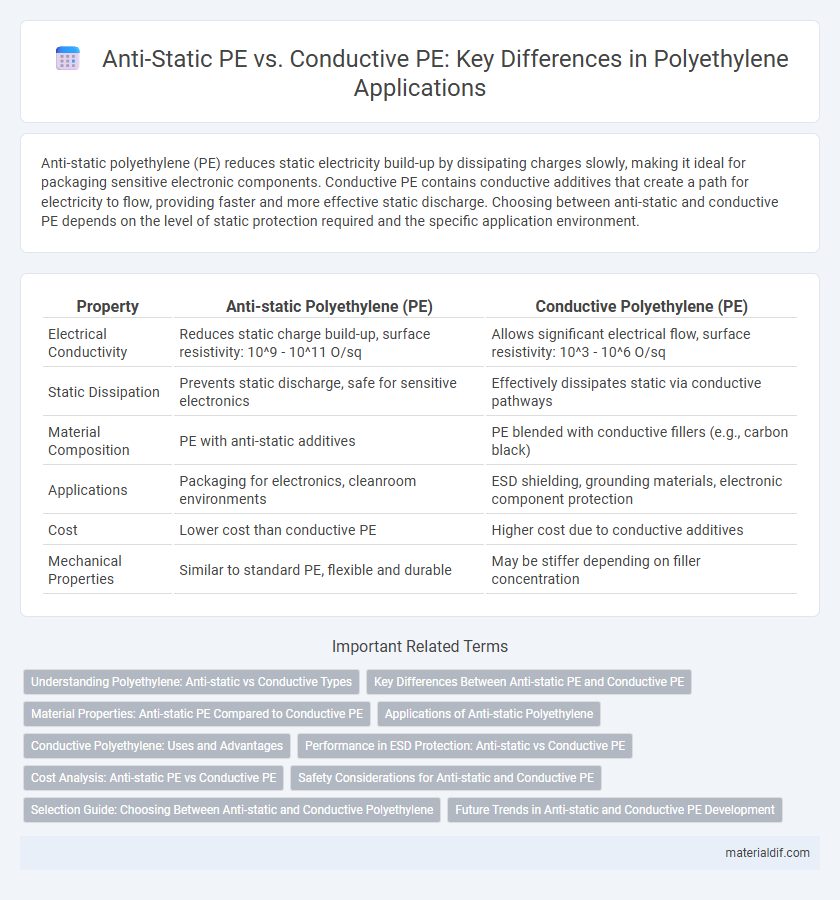

Anti-static polyethylene (PE) reduces static electricity build-up by dissipating charges slowly, making it ideal for packaging sensitive electronic components. Conductive PE contains conductive additives that create a path for electricity to flow, providing faster and more effective static discharge. Choosing between anti-static and conductive PE depends on the level of static protection required and the specific application environment.

Table of Comparison

| Property | Anti-static Polyethylene (PE) | Conductive Polyethylene (PE) |

|---|---|---|

| Electrical Conductivity | Reduces static charge build-up, surface resistivity: 10^9 - 10^11 O/sq | Allows significant electrical flow, surface resistivity: 10^3 - 10^6 O/sq |

| Static Dissipation | Prevents static discharge, safe for sensitive electronics | Effectively dissipates static via conductive pathways |

| Material Composition | PE with anti-static additives | PE blended with conductive fillers (e.g., carbon black) |

| Applications | Packaging for electronics, cleanroom environments | ESD shielding, grounding materials, electronic component protection |

| Cost | Lower cost than conductive PE | Higher cost due to conductive additives |

| Mechanical Properties | Similar to standard PE, flexible and durable | May be stiffer depending on filler concentration |

Understanding Polyethylene: Anti-static vs Conductive Types

Anti-static polyethylene (PE) reduces surface static charge by dissipating static electricity, preventing dust attraction and sparking in packaging and electronics applications. Conductive PE contains conductive fillers that create a continuous electrical path, enabling efficient charge dissipation and grounding in environments requiring higher conductivity standards. Understanding the differences helps select the appropriate PE type for controlling electrostatic discharge (ESD) risks in sensitive manufacturing and storage settings.

Key Differences Between Anti-static PE and Conductive PE

Anti-static polyethylene (PE) reduces surface static electricity to prevent dust attraction and minimize static discharge risks, while conductive PE contains conductive fillers like carbon black or metal fibers to provide a continuous electrical path for static charge dissipation. Anti-static PE is typically used in packaging sensitive electronics where low-level static control is needed, whereas conductive PE is essential for environments requiring effective grounding and higher electrical conductivity. The primary difference lies in their electrical resistivity levels: anti-static PE ranges from 10^9 to 10^12 ohms, and conductive PE has resistivity below 10^6 ohms.

Material Properties: Anti-static PE Compared to Conductive PE

Anti-static polyethylene (PE) exhibits surface resistivity in the range of 10^9 to 10^12 ohms per square, effectively reducing static charge buildup without permitting electrical current flow. Conductive PE, in contrast, has much lower resistivity, typically between 10^3 and 10^6 ohms per square, enabling it to dissipate electrical charges rapidly and prevent electrostatic discharge (ESD). The material properties of anti-static PE provide moderate static protection ideal for dust reduction and handling sensitive components, whereas conductive PE offers superior charge dissipation for high-risk environments requiring ground fault prevention.

Applications of Anti-static Polyethylene

Anti-static polyethylene is widely utilized in packaging sensitive electronic components, preventing electrostatic discharge (ESD) damage during handling and transportation. Its applications extend to cleanroom environments and medical device packaging, where static control is critical to maintaining product integrity. Compared to conductive PE, anti-static PE offers controlled surface resistance, making it ideal for environments requiring moderate static dissipation without full conductivity.

Conductive Polyethylene: Uses and Advantages

Conductive polyethylene is primarily used in electronic packaging, antistatic flooring, and cable jacketing due to its excellent ability to dissipate static electricity. Its intrinsic conductivity prevents electrostatic discharge (ESD) that can damage sensitive electronic components, making it ideal for cleanrooms and electronic device manufacturing. Advantages include improved safety, enhanced product longevity, and compliance with industry standards for ESD protection.

Performance in ESD Protection: Anti-static vs Conductive PE

Anti-static polyethylene (PE) offers moderate electrostatic discharge (ESD) protection by preventing static charge buildup through surface resistivity typically ranging from 10^9 to 10^11 ohms/square. Conductive PE provides superior ESD protection with much lower resistivity levels, often between 10^3 and 10^5 ohms/square, allowing faster dissipation of static charges. The choice between anti-static and conductive PE depends on the application's sensitivity to static discharge and the required level of charge neutralization speed.

Cost Analysis: Anti-static PE vs Conductive PE

Anti-static polyethylene (PE) typically incurs lower production and material costs compared to conductive PE due to the simpler additives and formulations required. Conductive PE demands specialized conductive fillers like carbon black or metal fibers, significantly increasing raw material expenses and processing complexity. Despite its higher upfront cost, conductive PE offers superior electrical performance and durability for applications requiring stringent static dissipation and grounding, justifying the investment in high-end industrial uses.

Safety Considerations for Anti-static and Conductive PE

Anti-static polyethylene (PE) reduces surface electrical charges to prevent dust attraction and minor static shocks, enhancing safety in environments with sensitive electronic components. Conductive PE dissipates static electricity more effectively by providing a controlled path to ground, crucial in explosive or highly flammable settings to avoid sparks. Proper grounding and material selection are vital to maximize safety benefits, ensuring compliance with industry standards for electrostatic discharge protection.

Selection Guide: Choosing Between Anti-static and Conductive Polyethylene

Anti-static polyethylene reduces surface static charge buildup by incorporating additives that dissipate electrical charges, suitable for packaging sensitive electronic components. Conductive polyethylene contains higher levels of conductive fillers, enabling it to conduct electricity and prevent electrostatic discharge in environments requiring grounding. Selection between anti-static and conductive PE depends on the required electrical resistance range, the sensitivity of the application, and environmental conditions to ensure optimal electrostatic protection.

Future Trends in Anti-static and Conductive PE Development

Future trends in anti-static and conductive polyethylene (PE) emphasize enhanced electrical dissipation properties through nano-composite additives and advanced carbon-based fillers such as graphene. Research focuses on achieving improved durability and environmental resistance while reducing additive migration to maintain consistent performance in packaging and electronics applications. Sustainable production methods, including bio-based polymers and recyclability enhancements, are driving innovation in the development of next-generation anti-static and conductive PE materials.

Anti-static PE vs Conductive PE Infographic

materialdif.com

materialdif.com