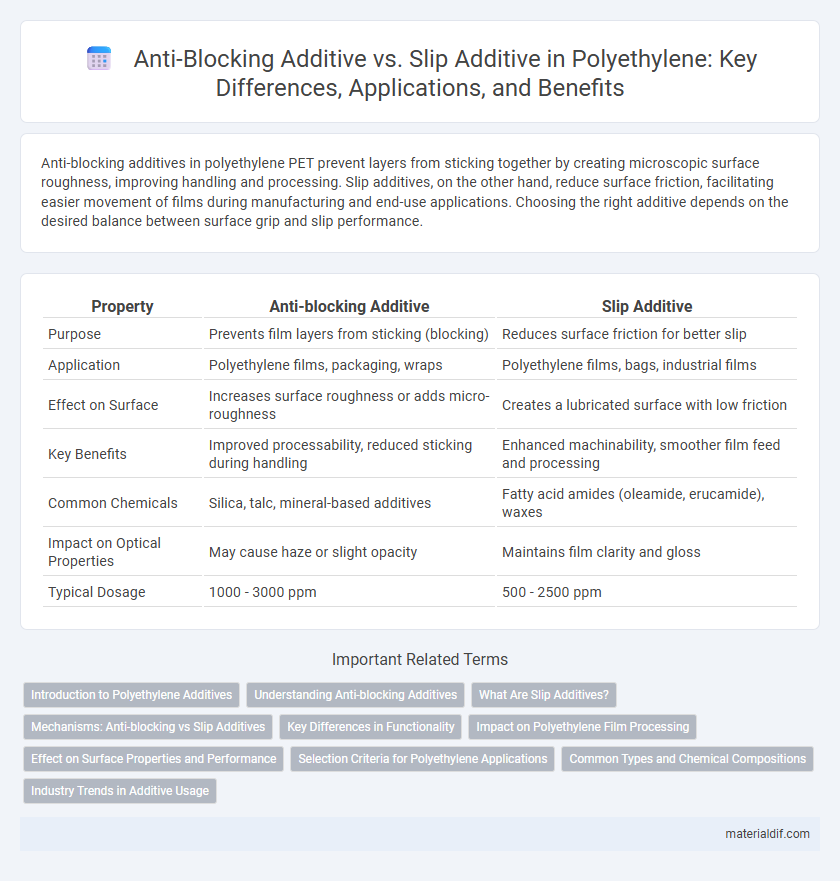

Anti-blocking additives in polyethylene PET prevent layers from sticking together by creating microscopic surface roughness, improving handling and processing. Slip additives, on the other hand, reduce surface friction, facilitating easier movement of films during manufacturing and end-use applications. Choosing the right additive depends on the desired balance between surface grip and slip performance.

Table of Comparison

| Property | Anti-blocking Additive | Slip Additive |

|---|---|---|

| Purpose | Prevents film layers from sticking (blocking) | Reduces surface friction for better slip |

| Application | Polyethylene films, packaging, wraps | Polyethylene films, bags, industrial films |

| Effect on Surface | Increases surface roughness or adds micro-roughness | Creates a lubricated surface with low friction |

| Key Benefits | Improved processability, reduced sticking during handling | Enhanced machinability, smoother film feed and processing |

| Common Chemicals | Silica, talc, mineral-based additives | Fatty acid amides (oleamide, erucamide), waxes |

| Impact on Optical Properties | May cause haze or slight opacity | Maintains film clarity and gloss |

| Typical Dosage | 1000 - 3000 ppm | 500 - 2500 ppm |

Introduction to Polyethylene Additives

Polyethylene additives enhance the material's performance by modifying surface properties; anti-blocking additives prevent layers of polyethylene film from sticking to each other, ensuring easy separation during handling and processing. Slip additives reduce the coefficient of friction on polyethylene surfaces, improving the film's slip characteristics and processing efficiency in converting operations. Both additives are essential in optimizing polyethylene film quality for packaging, providing balance between machinability and product appearance.

Understanding Anti-blocking Additives

Anti-blocking additives in polyethylene prevent film layers from sticking together by creating microscopic surface roughness, enhancing processing efficiency and end-use performance. These additives differ from slip additives, which reduce surface friction to improve film handling and prevent static buildup. Understanding the specific role of anti-blocking agents is essential for optimizing film clarity, strength, and ease of separation in packaging applications.

What Are Slip Additives?

Slip additives are specialized compounds incorporated into polyethylene to reduce surface friction, enhancing material flow during processing and improving the handling performance of films and sheets. These additives migrate to the polymer surface, creating a lubricating layer that facilitates easier separation of film layers and reduces static cling. Unlike anti-blocking agents, which prevent film layers from sticking together by increasing surface roughness, slip additives focus on optimizing surface slip properties for smoother processing and application.

Mechanisms: Anti-blocking vs Slip Additives

Anti-blocking additives in polyethylene create micro-rough surfaces that reduce adhesion between film layers by increasing surface friction, preventing blocking during storage or processing. Slip additives function by migrating to the polymer surface, forming a lubricating layer that decreases the coefficient of friction, enhancing processability and film handling. The differing mechanisms target either increasing surface roughness (anti-blocking) or reducing surface friction (slip), optimizing polyethylene film performance for various applications.

Key Differences in Functionality

Anti-blocking additives in polyethylene prevent film layers from sticking together by creating microscopic surface roughness, enhancing ease of unwinding and processing. Slip additives reduce the coefficient of friction on polyethylene surfaces, improving glide and handling during manufacturing and end-use applications. The key difference lies in anti-blocking additives controlling adhesion, while slip additives primarily modify surface friction properties.

Impact on Polyethylene Film Processing

Anti-blocking additives in polyethylene films increase surface roughness, preventing layers from sticking together without compromising clarity or mechanical properties, thus enhancing film unwind and stacking during processing. Slip additives reduce surface friction, facilitating smoother film transport through processing equipment and improving winding performance, but excessive use may affect surface aesthetics and printability. Balancing anti-blocking and slip additives optimizes polyethylene film processing by improving handling efficiency and maintaining desired film quality.

Effect on Surface Properties and Performance

Anti-blocking additives in polyethylene create microscopic surface roughness that prevents film layers from sticking together, enhancing clarity and ease of handling. Slip additives reduce surface friction by migrating to the film surface, improving processing speed and machinability without compromising the material's optical properties. Both additives significantly impact surface performance, with anti-blocking ensuring non-block adhesion and slip enhancing surface lubricity for industrial applications.

Selection Criteria for Polyethylene Applications

Selection criteria for polyethylene applications emphasize the balance between anti-blocking additives and slip additives, where anti-blocking agents prevent film layers from sticking together, ensuring smooth unwinding and processing, while slip additives reduce surface friction to enhance material handling and machinability. The choice depends on the specific application requirements, such as packaging films needing low blocking for clarity and ease of use, versus flexible films requiring optimal slip for improved transport and conversion efficiency. Consideration of factors like additive concentration, compatibility with polyethylene resin grades, and desired surface properties guides selecting the appropriate additive for performance optimization.

Common Types and Chemical Compositions

Anti-blocking additives in polyethylene commonly include silica, talc, and calcium carbonate, which create micro-roughness on film surfaces to prevent layers from sticking together. Slip additives primarily consist of erucamide, oleamide, and stearamide, which migrate to the surface to reduce friction and enhance film processability. The chemical composition of anti-block additives generally involves inorganic particles, whereas slip additives are typically long-chain fatty acid amides that function through surface lubrication.

Industry Trends in Additive Usage

Anti-blocking additives in polyethylene prevent film layers from sticking together, enhancing packaging efficiency and reducing waste, while slip additives improve surface lubrication, facilitating better processing and product handling. Recent industry trends show a growing preference for multifunctional additives that combine anti-blocking and slip properties to optimize performance and reduce costs. The demand for sustainable, bio-based additives is rising as manufacturers seek eco-friendly solutions complying with stricter environmental regulations.

Anti-blocking additive vs Slip additive Infographic

materialdif.com

materialdif.com