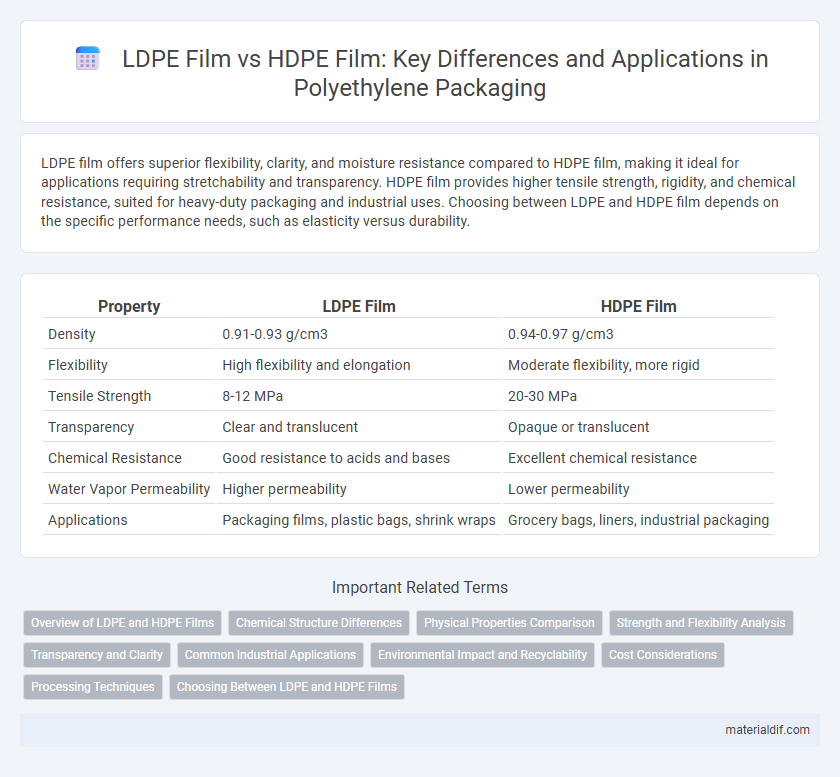

LDPE film offers superior flexibility, clarity, and moisture resistance compared to HDPE film, making it ideal for applications requiring stretchability and transparency. HDPE film provides higher tensile strength, rigidity, and chemical resistance, suited for heavy-duty packaging and industrial uses. Choosing between LDPE and HDPE film depends on the specific performance needs, such as elasticity versus durability.

Table of Comparison

| Property | LDPE Film | HDPE Film |

|---|---|---|

| Density | 0.91-0.93 g/cm3 | 0.94-0.97 g/cm3 |

| Flexibility | High flexibility and elongation | Moderate flexibility, more rigid |

| Tensile Strength | 8-12 MPa | 20-30 MPa |

| Transparency | Clear and translucent | Opaque or translucent |

| Chemical Resistance | Good resistance to acids and bases | Excellent chemical resistance |

| Water Vapor Permeability | Higher permeability | Lower permeability |

| Applications | Packaging films, plastic bags, shrink wraps | Grocery bags, liners, industrial packaging |

Overview of LDPE and HDPE Films

LDPE film is characterized by its flexibility, transparency, and excellent moisture barrier properties, making it ideal for packaging applications requiring stretch and clarity. HDPE film offers higher tensile strength, chemical resistance, and rigidity, commonly used in heavy-duty bags, liners, and containers. Both types of polyethylene films serve distinct purposes due to their molecular density differences, with LDPE having a lower density and HDPE possessing a higher density structure.

Chemical Structure Differences

LDPE film features a highly branched polymer chain structure, resulting in lower density and increased flexibility, while HDPE film exhibits a linear polymer structure with minimal branching, leading to higher density and superior tensile strength. The branched chains in LDPE reduce intermolecular forces, making it softer and more transparent compared to the rigid, crystalline structure of HDPE that enhances its chemical resistance and durability. These structural differences directly impact the films' mechanical properties and applications in packaging and industrial uses.

Physical Properties Comparison

LDPE film exhibits higher flexibility and elongation at break, making it ideal for applications requiring stretchability, with tensile strength typically ranging from 8 to 25 MPa. HDPE film offers greater stiffness, higher tensile strength between 20 and 40 MPa, and superior resistance to impact and environmental stress cracking. The density difference, with LDPE around 0.91-0.93 g/cm3 and HDPE about 0.94-0.97 g/cm3, influences their mechanical performance and suitability for distinct packaging and industrial uses.

Strength and Flexibility Analysis

Low-density polyethylene (LDPE) film exhibits superior flexibility and excellent elongation, making it ideal for applications requiring stretchability and impact resistance. High-density polyethylene (HDPE) film offers greater tensile strength and rigidity due to its higher crystallinity, providing enhanced durability for heavy-duty packaging and industrial use. LDPE's branched polymer structure contributes to its softness, while HDPE's linear chains result in a tougher, more abrasion-resistant film.

Transparency and Clarity

LDPE film offers superior transparency and clarity compared to HDPE film, making it ideal for applications where visual appeal is crucial. The molecular structure of LDPE results in a more flexible and less crystalline material, enhancing its light transmission properties. In contrast, HDPE film's higher density and crystallinity reduce transparency, resulting in a more opaque appearance suitable for protective packaging.

Common Industrial Applications

LDPE film is widely used in packaging for its flexibility and moisture resistance, making it ideal for food wrap, grocery bags, and squeeze bottles. HDPE film offers greater strength and chemical resistance, commonly utilized in heavy-duty bags, agricultural films, and protective coverings. Both materials serve critical roles in industries requiring durable, lightweight, and cost-effective plastic film solutions.

Environmental Impact and Recyclability

LDPE film typically has lower density and is more flexible than HDPE film, which affects its environmental footprint through increased degradation time in landfills. HDPE film is generally more widely accepted in recycling programs due to its higher density and consistent polymer structure, enabling easier processing and higher quality recycled outputs. Choosing HDPE film can reduce environmental impact by enhancing recyclability rates and minimizing waste accumulation.

Cost Considerations

LDPE film typically costs more than HDPE film due to its superior flexibility and clarity, making it ideal for packaging applications that require softness and transparency. HDPE film offers a more economical option with higher tensile strength and better chemical resistance, suitable for heavy-duty uses such as grocery bags and agricultural covers. Choosing between LDPE and HDPE film depends on balancing budget constraints with the specific material properties required for the application.

Processing Techniques

LDPE film is produced through a low-pressure polymerization process using free radical polymerization, resulting in a branched polymer structure ideal for film extrusion and blown film techniques. HDPE film is manufactured via high-pressure or catalyst-based polymerization, creating a linear polymer with higher density, processed primarily through cast film and extrusion blow molding methods. The differences in polymer branching influence melt flow characteristics, making LDPE more flexible and easier to process for thin films, while HDPE offers stronger mechanical properties but requires precise temperature control during processing.

Choosing Between LDPE and HDPE Films

LDPE film offers superior flexibility, clarity, and sealability, making it ideal for lightweight packaging and applications requiring stretchability. HDPE film provides higher tensile strength, stiffness, and chemical resistance, suited for heavy-duty packaging and industrial uses. Selecting between LDPE and HDPE films depends on the balance of durability, transparency, and cost efficiency required for specific packaging needs.

LDPE Film vs HDPE Film Infographic

materialdif.com

materialdif.com