Rotomolding produces hollow polyethylene PET products with uniform wall thickness and excellent durability, making it ideal for large, complex shapes. Thermoforming shapes sheets of PET into thin, lightweight items with precise detail and faster production cycles. Choosing between rotomolding and thermoforming depends on the product's design requirements, volume, and mechanical strength needed.

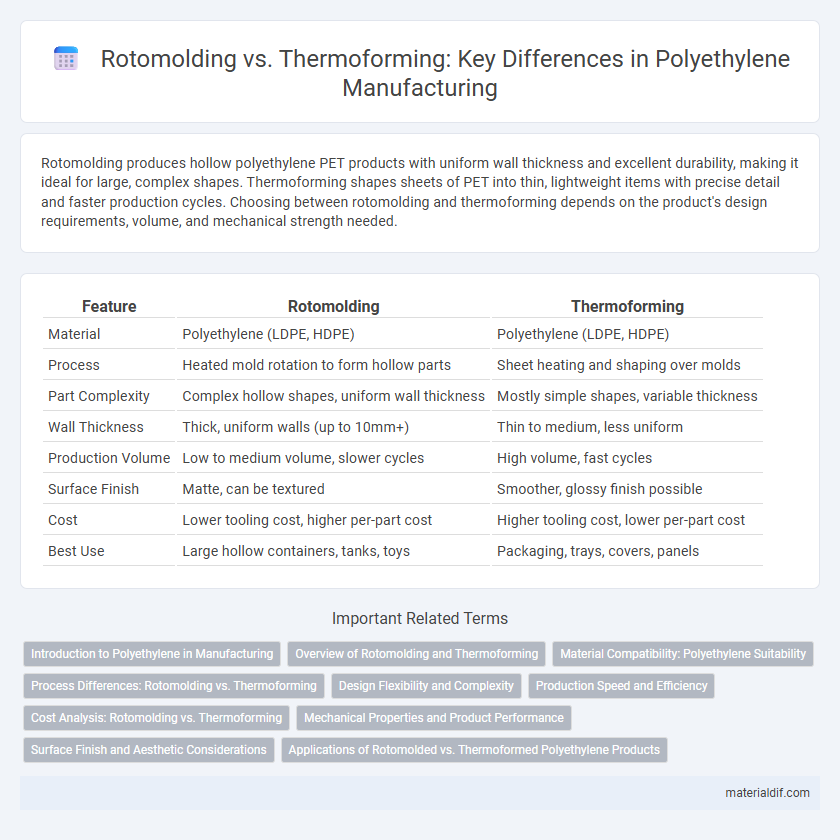

Table of Comparison

| Feature | Rotomolding | Thermoforming |

|---|---|---|

| Material | Polyethylene (LDPE, HDPE) | Polyethylene (LDPE, HDPE) |

| Process | Heated mold rotation to form hollow parts | Sheet heating and shaping over molds |

| Part Complexity | Complex hollow shapes, uniform wall thickness | Mostly simple shapes, variable thickness |

| Wall Thickness | Thick, uniform walls (up to 10mm+) | Thin to medium, less uniform |

| Production Volume | Low to medium volume, slower cycles | High volume, fast cycles |

| Surface Finish | Matte, can be textured | Smoother, glossy finish possible |

| Cost | Lower tooling cost, higher per-part cost | Higher tooling cost, lower per-part cost |

| Best Use | Large hollow containers, tanks, toys | Packaging, trays, covers, panels |

Introduction to Polyethylene in Manufacturing

Polyethylene is a versatile thermoplastic widely used in manufacturing due to its durability, chemical resistance, and lightweight properties. In rotomolding, polyethylene powders are heated and rotated inside a mold to create hollow, seamless products ideal for large, complex shapes. Thermoforming involves heating polyethylene sheets until pliable, then molding them over a form, suitable for creating thin-walled, detailed components with faster production cycles.

Overview of Rotomolding and Thermoforming

Rotomolding, or rotational molding, involves heating polyethylene in a mold that rotates biaxially to create hollow, seamless products with uniform wall thickness, ideal for large, complex shapes like tanks and containers. Thermoforming heats polyethylene sheets until pliable, then molds them into shapes using vacuum or pressure, best suited for creating thinner parts such as packaging and trays with faster cycle times. Both processes utilize polyethylene's thermoplastic properties but differ in applications, cost efficiency, and product design flexibility.

Material Compatibility: Polyethylene Suitability

Polyethylene exhibits excellent compatibility with rotomolding due to its low melting point and high molecular weight, allowing uniform wall thickness and seamless hollow parts. Thermoforming, while suitable for polyethylene sheets, often encounters challenges with maintaining structural integrity in thin or complex shapes. The molecular structure of polyethylene enhances its flexibility and impact resistance, making it particularly advantageous for rotomolded applications compared to thermoformed products.

Process Differences: Rotomolding vs. Thermoforming

Rotomolding involves heating powdered polyethylene inside a rotating mold to achieve uniform thickness and seamless hollow parts, making it ideal for large, complex shapes. Thermoforming heats polyethylene sheets until pliable, then forms them over a mold using vacuum or pressure, producing thinner, more detailed components with faster cycle times. Rotomolding excels in durability and wall thickness consistency, while thermoforming offers higher precision and efficiency for thinner, flat or moderately contoured polyethylene products.

Design Flexibility and Complexity

Rotomolding offers superior design flexibility for polyethylene products due to its ability to create complex, seamless shapes with uniform wall thickness, ideal for large or intricate geometries. Thermoforming is limited by the sheet's stretch capabilities, often resulting in less detailed designs and thinner sections in areas with sharp bends or deep draws. For applications requiring durable, complex shapes with consistent material distribution, rotomolding remains the preferred manufacturing process.

Production Speed and Efficiency

Rotomolding offers slower production speed due to its cycle times, typically ranging from 15 to 60 minutes per part, but excels in producing complex, hollow polyethylene products with minimal tooling costs. Thermoforming provides much faster production rates, with cycle times often under a minute, making it highly efficient for high-volume, thin-gauge polyethylene components. Efficiency in thermoforming stems from rapid heating and cooling processes, while rotomolding's efficiency lies in material economy and design flexibility for large, seamless parts.

Cost Analysis: Rotomolding vs. Thermoforming

Rotomolding typically incurs lower mold costs due to the simplicity of molds compared to thermoforming, which requires more expensive, complex tooling. Production costs in rotomolding are higher because of longer cycle times, whereas thermoforming offers faster production rates and lower labor expenses. Overall, rotomolding suits low to medium volume polyethylene products where cost efficiency in tooling is critical, while thermoforming is more cost-effective for high-volume runs demanding rapid output.

Mechanical Properties and Product Performance

Rotomolding produces polyethylene parts with uniform wall thickness and excellent impact resistance, making them ideal for heavy-duty applications and complex shapes. Thermoforming offers higher dimensional accuracy and surface finish but results in thinner walls and lower impact strength compared to rotomolded parts. Mechanical properties like tensile strength and elongation are generally superior in rotomolded polyethylene products, enhancing durability and long-term product performance.

Surface Finish and Aesthetic Considerations

Rotomolding typically produces seamless, uniform surfaces with consistent thickness, ideal for complex shapes but often exhibits a matte finish that may require post-processing for enhanced aesthetics. Thermoforming offers smoother, glossier surfaces with sharper details and better definition, making it preferable for applications demanding high visual appeal and intricate patterns. Surface finish quality directly impacts design choices, where rotomolding prioritizes structural integrity and thermoforming emphasizes visual finesse.

Applications of Rotomolded vs. Thermoformed Polyethylene Products

Rotomolded polyethylene products excel in producing large, hollow items such as tanks, playground equipment, and kayaks due to their uniform wall thickness and durability. Thermoformed polyethylene is preferred for creating thinner, detailed items like packaging trays, food containers, and protective covers, benefiting from faster production cycles. The choice hinges on application requirements, with rotomolding suited for robust, volumetric shapes and thermoforming ideal for lightweight, intricate designs.

Rotomolding vs Thermoforming Infographic

materialdif.com

materialdif.com