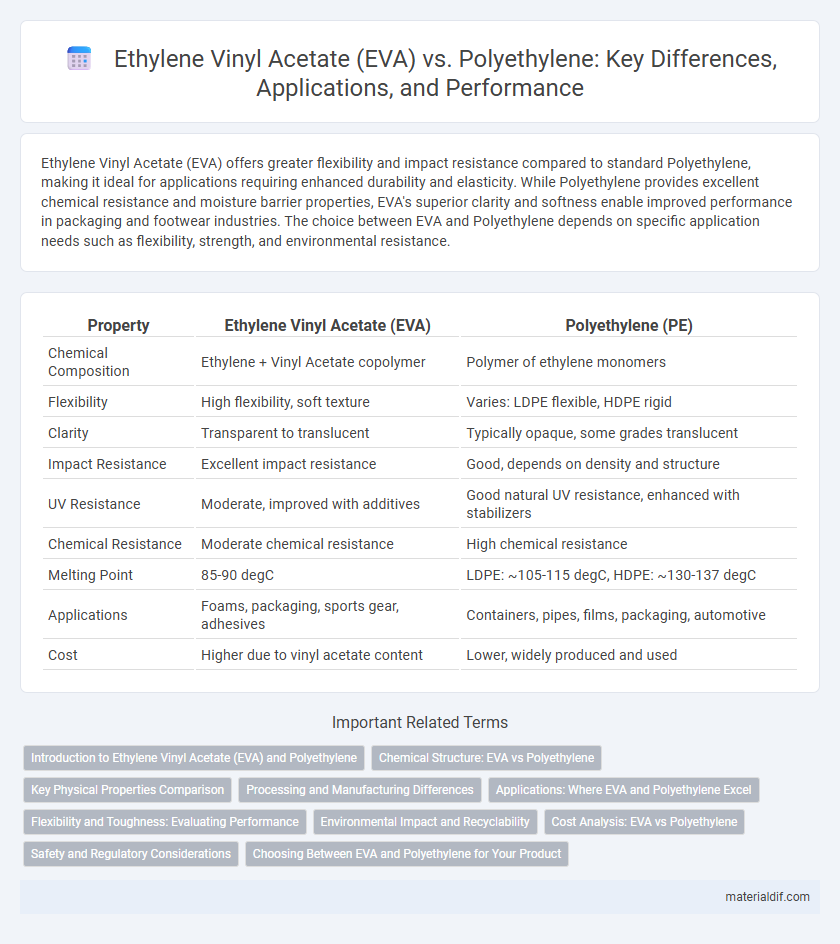

Ethylene Vinyl Acetate (EVA) offers greater flexibility and impact resistance compared to standard Polyethylene, making it ideal for applications requiring enhanced durability and elasticity. While Polyethylene provides excellent chemical resistance and moisture barrier properties, EVA's superior clarity and softness enable improved performance in packaging and footwear industries. The choice between EVA and Polyethylene depends on specific application needs such as flexibility, strength, and environmental resistance.

Table of Comparison

| Property | Ethylene Vinyl Acetate (EVA) | Polyethylene (PE) |

|---|---|---|

| Chemical Composition | Ethylene + Vinyl Acetate copolymer | Polymer of ethylene monomers |

| Flexibility | High flexibility, soft texture | Varies: LDPE flexible, HDPE rigid |

| Clarity | Transparent to translucent | Typically opaque, some grades translucent |

| Impact Resistance | Excellent impact resistance | Good, depends on density and structure |

| UV Resistance | Moderate, improved with additives | Good natural UV resistance, enhanced with stabilizers |

| Chemical Resistance | Moderate chemical resistance | High chemical resistance |

| Melting Point | 85-90 degC | LDPE: ~105-115 degC, HDPE: ~130-137 degC |

| Applications | Foams, packaging, sports gear, adhesives | Containers, pipes, films, packaging, automotive |

| Cost | Higher due to vinyl acetate content | Lower, widely produced and used |

Introduction to Ethylene Vinyl Acetate (EVA) and Polyethylene

Ethylene Vinyl Acetate (EVA) is a copolymer composed of ethylene and vinyl acetate, known for its flexibility, clarity, and excellent impact resistance, making it suitable for applications like footwear, packaging films, and solar panel encapsulation. Polyethylene (PE), a polymer of ethylene, is available in various densities such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE), valued for its chemical resistance, durability, and versatility in packaging, containers, and plastic bags. Both EVA and PE share ethylene as a base monomer, but differ significantly in mechanical properties and application scopes due to the vinyl acetate content in EVA, which enhances softness and adhesiveness.

Chemical Structure: EVA vs Polyethylene

Ethylene Vinyl Acetate (EVA) is a copolymer composed of ethylene and vinyl acetate monomers, introducing polar acetate groups into the polymer chain, which enhances flexibility and adhesion properties. Polyethylene is a homopolymer made solely from ethylene monomers, resulting in a non-polar, crystalline structure with excellent chemical resistance and tensile strength. The presence of vinyl acetate units in EVA disrupts polyethylene's crystalline structure, lowering density and increasing elasticity compared to the more rigid and dense polyethylene chains.

Key Physical Properties Comparison

Ethylene Vinyl Acetate (EVA) exhibits greater flexibility and impact resistance compared to polyethylene, making it ideal for applications requiring softness and durability. Polyethylene generally offers higher tensile strength and chemical resistance, suited for packaging and piping uses. The density of EVA is typically lower than that of polyethylene, affecting their mechanical performance and weight considerations in product design.

Processing and Manufacturing Differences

Ethylene Vinyl Acetate (EVA) differs from Polyethylene in processing due to its lower crystallinity, which allows for easier melting and greater flexibility during extrusion and molding. EVA typically requires lower processing temperatures, around 80-130degC, compared to Polyethylene's range of 120-190degC, reducing energy consumption and thermal degradation risks. Manufacturing EVA involves controlling vinyl acetate content to adjust softness and transparency, whereas Polyethylene processing focuses more on controlling density and branching to influence strength and rigidity.

Applications: Where EVA and Polyethylene Excel

Ethylene Vinyl Acetate (EVA) excels in applications requiring softness, flexibility, and clarity, such as foam products, adhesives, and packaging films, due to its excellent elasticity and transparency. Polyethylene, especially high-density polyethylene (HDPE) and low-density polyethylene (LDPE), dominates in rigid packaging, piping, and containers because of its superior chemical resistance, toughness, and cost-effectiveness. Both polymers serve distinct markets, with EVA preferred for cushioning and flexible seals, while polyethylene is favored in heavy-duty, durable applications.

Flexibility and Toughness: Evaluating Performance

Ethylene Vinyl Acetate (EVA) offers superior flexibility compared to Polyethylene, making it ideal for applications requiring stretch and resilience, such as foam cushioning and flexible packaging. Polyethylene exhibits higher toughness, providing excellent impact resistance and durability, which is essential for heavy-duty containers and piping. Evaluating performance between EVA and Polyethylene depends on balancing the need for flexibility against the requirement for structural strength and toughness.

Environmental Impact and Recyclability

Ethylene Vinyl Acetate (EVA) and Polyethylene differ significantly in environmental impact and recyclability, with Polyethylene being more widely recyclable due to its simpler polymer structure and established recycling streams. EVA, while offering flexibility and durability benefits, presents challenges in recycling because of its copolymer nature and the presence of vinyl acetate, which can complicate processing and degrade recycling quality. Polyethylene's lower environmental footprint and higher recyclability rates make it a preferable option in applications prioritizing sustainability.

Cost Analysis: EVA vs Polyethylene

Ethylene Vinyl Acetate (EVA) typically incurs higher production costs compared to Polyethylene due to its complex copolymerization process and the incorporation of vinyl acetate monomers. Polyethylene remains more cost-effective for large-scale applications, benefiting from established manufacturing efficiencies and lower raw material expenses. In market pricing, EVA commands premium pricing driven by enhanced properties such as flexibility and clarity, while Polyethylene's affordability supports widespread use in packaging and consumer goods.

Safety and Regulatory Considerations

Ethylene Vinyl Acetate (EVA) offers enhanced flexibility and impact resistance compared to Polyethylene, but safety assessments highlight its lower chemical inertness, requiring more stringent regulatory scrutiny in food contact applications. Polyethylene, widely recognized for its inertness and high chemical resistance, benefits from extensive regulatory approvals, including FDA and EU certifications for food and pharmaceutical uses. When selecting materials, manufacturers must balance EVA's mechanical advantages against Polyethylene's superior safety profile and compliance with global regulatory standards.

Choosing Between EVA and Polyethylene for Your Product

Ethylene Vinyl Acetate (EVA) offers superior flexibility, clarity, and impact resistance compared to Polyethylene, making it ideal for applications requiring enhanced elasticity and transparency. Polyethylene excels in chemical resistance, cost-effectiveness, and durability, often preferred for packaging, containers, and piping due to its robust mechanical properties. Selecting between EVA and Polyethylene depends on product requirements such as flexibility, environmental stress resistance, and budget constraints.

Ethylene Vinyl Acetate (EVA) vs Polyethylene Infographic

materialdif.com

materialdif.com