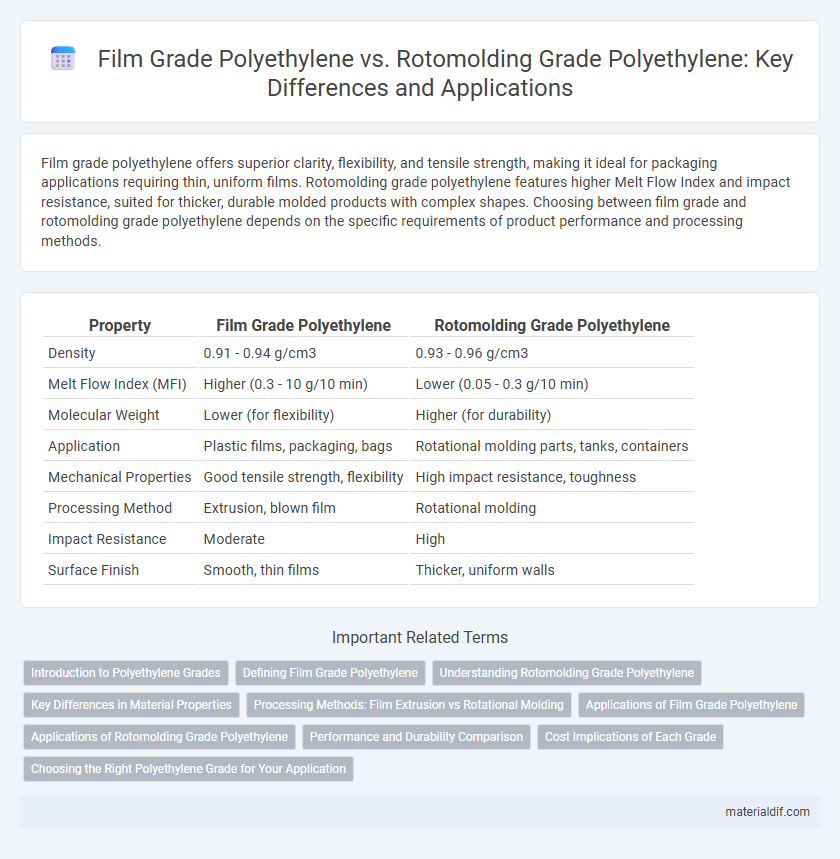

Film grade polyethylene offers superior clarity, flexibility, and tensile strength, making it ideal for packaging applications requiring thin, uniform films. Rotomolding grade polyethylene features higher Melt Flow Index and impact resistance, suited for thicker, durable molded products with complex shapes. Choosing between film grade and rotomolding grade polyethylene depends on the specific requirements of product performance and processing methods.

Table of Comparison

| Property | Film Grade Polyethylene | Rotomolding Grade Polyethylene |

|---|---|---|

| Density | 0.91 - 0.94 g/cm3 | 0.93 - 0.96 g/cm3 |

| Melt Flow Index (MFI) | Higher (0.3 - 10 g/10 min) | Lower (0.05 - 0.3 g/10 min) |

| Molecular Weight | Lower (for flexibility) | Higher (for durability) |

| Application | Plastic films, packaging, bags | Rotational molding parts, tanks, containers |

| Mechanical Properties | Good tensile strength, flexibility | High impact resistance, toughness |

| Processing Method | Extrusion, blown film | Rotational molding |

| Impact Resistance | Moderate | High |

| Surface Finish | Smooth, thin films | Thicker, uniform walls |

Introduction to Polyethylene Grades

Film grade polyethylene is specifically formulated for producing thin, flexible films with high clarity and excellent tensile strength, making it ideal for packaging applications. Rotomolding grade polyethylene features a higher molecular weight and unique flow characteristics, optimized for rotational molding processes to create durable, thick-walled hollow products. Understanding the distinct molecular structures and processing requirements of these polyethylene grades is essential for selecting the right material to achieve desired mechanical properties and manufacturing efficiency.

Defining Film Grade Polyethylene

Film Grade Polyethylene is a specialized type of polyethylene resin designed for producing thin, flexible films used in packaging, agriculture, and industrial applications due to its excellent tensile strength, puncture resistance, and clarity. This grade features a lower density and higher molecular weight distribution, optimizing it for blow molding and cast film extrusion processes. In contrast, Rotomolding Grade Polyethylene is engineered for rotational molding with higher melt flow index and enhanced thermal stability to produce thick, durable hollow products.

Understanding Rotomolding Grade Polyethylene

Rotomolding grade polyethylene is specifically formulated for rotational molding processes, emphasizing high melt strength and excellent clarity to create seamless, durable parts. Unlike film grade polyethylene, which prioritizes thin, flexible, and tear-resistant properties for packaging applications, rotomolding grade polyethylene ensures uniform wall thickness and structural integrity in molded products. Its molecular weight distribution and thermal stability are optimized to withstand the slow cooling rates and reheating cycles characteristic of rotomolding.

Key Differences in Material Properties

Film grade polyethylene exhibits higher clarity, flexibility, and tensile strength, making it ideal for applications like packaging and plastic bags. Rotomolding grade polyethylene offers superior impact resistance, density, and stress crack resistance, suited for manufacturing durable hollow products. Differences in molecular weight distribution and polymer density drive variations in processing behavior and end-use performance.

Processing Methods: Film Extrusion vs Rotational Molding

Film Grade Polyethylene is specifically designed for film extrusion processes, offering high melt strength and clarity essential for creating thin, flexible films used in packaging and agricultural applications. Rotomolding Grade Polyethylene features higher molecular weight and enhanced thermal stability, optimized for the slow heating and cooling cycles of rotational molding, producing thick, seamless, and durable hollow parts. The key processing difference lies in film extrusion's continuous, high-speed line shaping thin layers versus rotational molding's batch process of melting powder inside a rotating mold to form complex three-dimensional shapes.

Applications of Film Grade Polyethylene

Film grade polyethylene is primarily used in packaging applications due to its excellent clarity, flexibility, and strength, making it ideal for plastic bags, stretch films, and agricultural covers. Its low density and superior sealing properties allow for effective moisture and oxygen barriers, preserving food and other products. This grade is engineered for high productivity in blown and cast film processes, ensuring consistent thickness and high-quality finish.

Applications of Rotomolding Grade Polyethylene

Rotomolding grade polyethylene is tailored for rotational molding processes, producing hollow and complex-shaped products such as tanks, containers, and automotive components. Its high impact resistance, stress crack resistance, and excellent chemical resistance make it ideal for durable industrial and consumer applications. Unlike film grade polyethylene, it exhibits superior melt flow properties and structural integrity required for thick-wall molding.

Performance and Durability Comparison

Film grade polyethylene is engineered for exceptional flexibility and tensile strength, making it ideal for applications like packaging films that demand durability against tearing and punctures. Rotomolding grade polyethylene, characterized by higher molecular weight and enhanced impact resistance, provides superior durability and structural integrity for molded products subjected to heavy mechanical stress and harsh environmental conditions. Performance-wise, film grade excels in lightweight, flexible applications, whereas rotomolding grade offers robust toughness and longevity in thick, rigid items.

Cost Implications of Each Grade

Film grade polyethylene typically incurs lower raw material costs due to its thinner gauge and higher production efficiency in blown or cast film processes, making it economically advantageous for large-scale packaging applications. Rotomolding grade polyethylene demands higher expenses owing to its enhanced molecular weight and specialized additives that improve impact resistance and thermal stability, which increase the overall material and processing costs. Selecting between film grade and rotomolding grade polyethylene significantly impacts budget allocation based on the specific performance requirements and production volumes of the intended product.

Choosing the Right Polyethylene Grade for Your Application

Film grade polyethylene offers superior clarity, flexibility, and tensile strength, making it ideal for packaging films and plastic bags requiring durability and transparency. Rotomolding grade polyethylene features higher molecular weight and enhanced impact resistance, suited for large hollow products like tanks and containers that demand structural integrity and toughness. Selecting the right polyethylene grade depends on specific application requirements such as mechanical properties, processing method, and end-use performance.

Film Grade Polyethylene vs Rotomolding Grade Polyethylene Infographic

materialdif.com

materialdif.com