Polyethylene PET exhibits minimal monomer migration due to its high polymer stability, which ensures the integrity of the material under varying conditions. The strong covalent bonds in the polymer chain resist degradation and leaching of residual monomers, enhancing safety in food and beverage packaging. This stability also extends the shelf life of packaged products by maintaining barrier properties and preventing contamination.

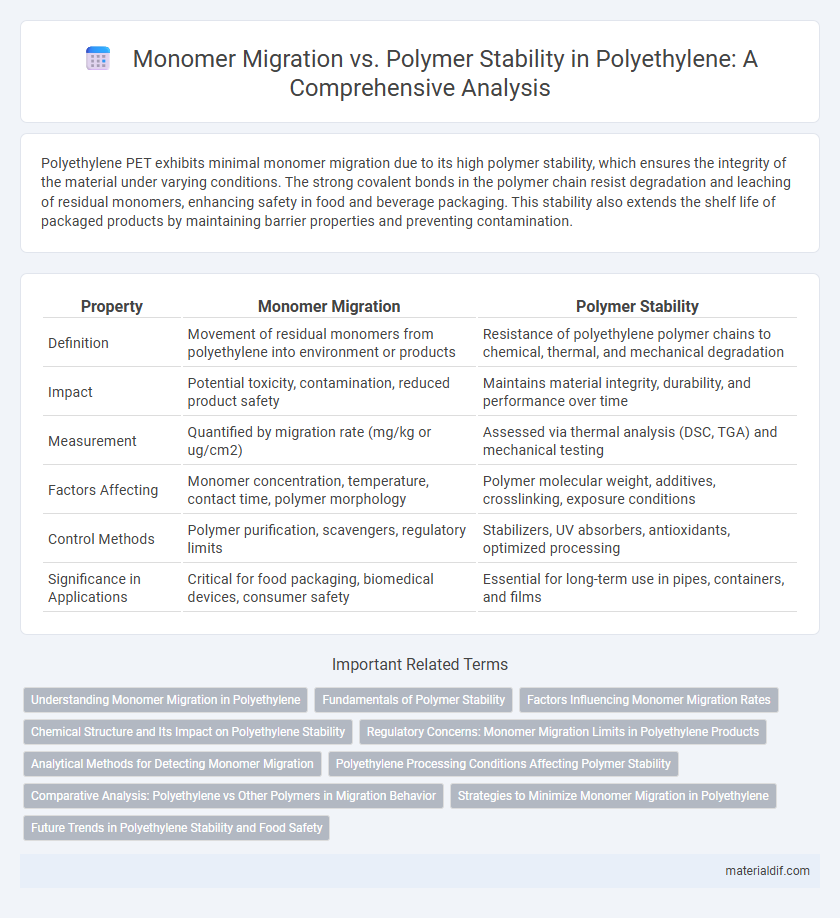

Table of Comparison

| Property | Monomer Migration | Polymer Stability |

|---|---|---|

| Definition | Movement of residual monomers from polyethylene into environment or products | Resistance of polyethylene polymer chains to chemical, thermal, and mechanical degradation |

| Impact | Potential toxicity, contamination, reduced product safety | Maintains material integrity, durability, and performance over time |

| Measurement | Quantified by migration rate (mg/kg or ug/cm2) | Assessed via thermal analysis (DSC, TGA) and mechanical testing |

| Factors Affecting | Monomer concentration, temperature, contact time, polymer morphology | Polymer molecular weight, additives, crosslinking, exposure conditions |

| Control Methods | Polymer purification, scavengers, regulatory limits | Stabilizers, UV absorbers, antioxidants, optimized processing |

| Significance in Applications | Critical for food packaging, biomedical devices, consumer safety | Essential for long-term use in pipes, containers, and films |

Understanding Monomer Migration in Polyethylene

Monomer migration in polyethylene primarily involves the diffusion of residual ethylene monomers trapped within the polymer matrix, which can affect product purity and performance over time. Polymer stability is influenced by the molecular weight distribution and the presence of additives that minimize monomer mobility and prevent degradation. Advanced analytical techniques such as gas chromatography and spectroscopy enable precise monitoring of monomer migration rates to optimize polyethylene formulations for enhanced durability and safety.

Fundamentals of Polymer Stability

Monomer migration in polyethylene impacts polymer stability by influencing the material's mechanical and chemical integrity over time. The fundamental factors of polymer stability include polymer chain length, crystallinity, and molecular weight distribution, which determine resistance to degradation and monomer release. Controlling polymerization conditions and additives can minimize residual monomers, enhancing the overall stability and performance of polyethylene products in diverse applications.

Factors Influencing Monomer Migration Rates

Monomer migration rates in polyethylene are influenced by factors such as polymer crystallinity, molecular weight, and temperature. Higher crystallinity reduces free volume, limiting monomer diffusion, while increased temperature enhances molecular mobility, accelerating migration. Additives and polymer morphology also critically impact the stability and migration behavior of monomers within polyethylene matrices.

Chemical Structure and Its Impact on Polyethylene Stability

Polyethylene stability is significantly influenced by its chemical structure, where the monomer ethylene forms long hydrocarbon chains with strong C-C and C-H bonds that resist degradation. Monomer migration is minimal due to the polymer's high molecular weight and dense packing, which limits the diffusion of residual ethylene units. The saturated hydrocarbon backbone enhances resistance to chemical attack, oxidative degradation, and thermal breakdown, thereby improving overall polymer stability.

Regulatory Concerns: Monomer Migration Limits in Polyethylene Products

Monomer migration in polyethylene products poses significant regulatory concerns due to potential health risks from residual ethylene or other monomers leaching into food or consumer goods. Regulatory agencies like the FDA and EFSA establish strict monomer migration limits, typically measured in parts per million (ppm), to ensure product safety and compliance in food contact applications. Ensuring polymer stability through optimized polymerization processes and additive use minimizes monomer migration, meeting industry standards and reducing the risk of regulatory breaches.

Analytical Methods for Detecting Monomer Migration

Analytical methods for detecting monomer migration in polyethylene primarily involve gas chromatography-mass spectrometry (GC-MS) due to its high sensitivity and specificity in identifying trace monomers like ethylene. Fourier-transform infrared spectroscopy (FTIR) complements GC-MS by characterizing polymer stability and detecting chemical changes related to monomer release. Thermal desorption techniques combined with chromatographic analysis further enhance detection limits and provide insights into the interaction between monomer migration and polymer degradation pathways.

Polyethylene Processing Conditions Affecting Polymer Stability

Polyethylene processing conditions such as temperature, residence time, and shear stress critically influence polymer stability by affecting monomer migration rates within the polymer matrix. Elevated temperatures accelerate free-radical degradation, increasing ethylene monomer diffusion and reducing molecular weight, which compromises mechanical properties. Controlled cooling and optimized extrusion parameters mitigate monomer migration and enhance polymer chain integrity, ensuring long-term stability in polyethylene applications.

Comparative Analysis: Polyethylene vs Other Polymers in Migration Behavior

Polyethylene exhibits lower monomer migration rates compared to polymers like polystyrene and polyvinyl chloride due to its chemically stable ethylene monomer units and high crystallinity. The intrinsic polymer stability of polyethylene reduces the diffusion of residual monomers, enhancing its safety profile in food packaging applications. Comparative studies highlight that polyethylene's non-polar backbone contributes to reduced monomer leaching relative to polar polymers, which tend to have higher migration tendencies under similar conditions.

Strategies to Minimize Monomer Migration in Polyethylene

Minimizing monomer migration in polyethylene involves optimizing polymerization conditions to reduce residual ethylene monomer content, thus enhancing polymer stability. Incorporating advanced catalysts such as metallocenes can control polymer chain growth more precisely, decreasing unreacted monomer presence. Post-polymerization treatments like thermal annealing or vacuum degassing effectively remove entrapped monomers, further stabilizing polyethylene products.

Future Trends in Polyethylene Stability and Food Safety

Future trends in polyethylene stability emphasize advanced monomer migration control to enhance food safety by reducing residual ethylene content and minimizing additive leaching. Innovations in copolymerization and barrier technologies improve polymer resistance to degradation, ensuring long-term stability and compliance with stringent regulatory standards. Emerging bio-based stabilizers and nanocomposite materials offer sustainable solutions to further inhibit monomer migration while maintaining polyethylene's mechanical properties for food packaging applications.

Monomer migration vs Polymer stability Infographic

materialdif.com

materialdif.com