Metallocene polyethylene offers superior clarity, flexibility, and uniformity compared to conventional polyethylene due to its advanced catalyst technology, resulting in enhanced mechanical properties and better processability. Its narrow molecular weight distribution and precise polymer architecture provide improved strength, toughness, and sealability, making it ideal for high-performance packaging applications. Conventional polyethylene, while cost-effective and widely used, often lacks the consistency and refined characteristics found in metallocene variants, impacting product quality and versatility.

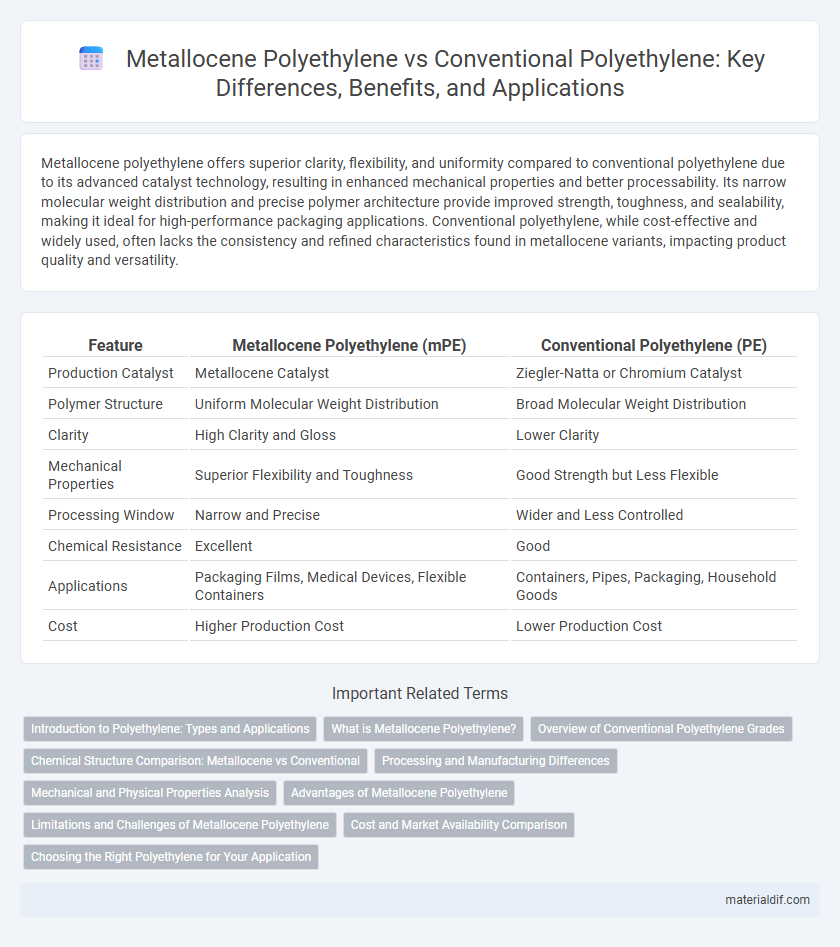

Table of Comparison

| Feature | Metallocene Polyethylene (mPE) | Conventional Polyethylene (PE) |

|---|---|---|

| Production Catalyst | Metallocene Catalyst | Ziegler-Natta or Chromium Catalyst |

| Polymer Structure | Uniform Molecular Weight Distribution | Broad Molecular Weight Distribution |

| Clarity | High Clarity and Gloss | Lower Clarity |

| Mechanical Properties | Superior Flexibility and Toughness | Good Strength but Less Flexible |

| Processing Window | Narrow and Precise | Wider and Less Controlled |

| Chemical Resistance | Excellent | Good |

| Applications | Packaging Films, Medical Devices, Flexible Containers | Containers, Pipes, Packaging, Household Goods |

| Cost | Higher Production Cost | Lower Production Cost |

Introduction to Polyethylene: Types and Applications

Metallocene polyethylene offers enhanced molecular uniformity and improved mechanical properties compared to conventional polyethylene, which typically features a broader polymer chain distribution. Conventional polyethylene types, such as high-density (HDPE) and low-density polyethylene (LDPE), are widely used in packaging, containers, and pipes due to their versatility and cost-effectiveness. Metallocene polyethylene's precise catalyst control enables applications requiring superior clarity, toughness, and sealability, making it ideal for high-performance films and medical devices.

What is Metallocene Polyethylene?

Metallocene polyethylene is a type of polyethylene produced using metallocene catalysts, which enable precise control over polymer structure, resulting in uniform molecular weight distribution and enhanced material properties. This advanced polymer exhibits superior clarity, toughness, and flexibility compared to conventional polyethylene, making it ideal for applications like flexible packaging and medical films. The unique catalyst technology allows tailored polymerization processes, yielding polyethylene with specific characteristics unattainable by traditional Ziegler-Natta catalysis.

Overview of Conventional Polyethylene Grades

Conventional polyethylene grades, including LDPE, HDPE, and LLDPE, are widely used due to their versatile properties such as high chemical resistance, mechanical strength, and ease of processing. These grades are produced using traditional Ziegler-Natta or chromium-based catalysts, resulting in a broader molecular weight distribution and less uniform polymer chains compared to metallocene polyethylene. While conventional polyethylene offers cost-effective solutions for applications like packaging, pipes, and containers, it typically lacks the enhanced clarity and stiffness found in metallocene-derived polymers.

Chemical Structure Comparison: Metallocene vs Conventional

Metallocene polyethylene features a uniform chemical structure with precisely controlled molecular weight distribution and comonomer placement, resulting in consistent branching and enhanced material properties. In contrast, conventional polyethylene, produced using Ziegler-Natta catalysts, exhibits broader molecular weight distribution and less controlled branching, leading to variable mechanical and optical characteristics. This fundamental difference in catalyst technology drives the distinct molecular architectures and performance profiles between metallocene and conventional polyethylene.

Processing and Manufacturing Differences

Metallocene polyethylene exhibits superior uniformity in molecular weight distribution compared to conventional polyethylene, resulting in enhanced processability during manufacturing. The precise catalyst control in metallocene polymerization enables the production of polymers with tailored properties, facilitating easier extrusion and molding. Conventional polyethylene often requires higher processing temperatures and pressures, whereas metallocene polyethylene allows for lower energy consumption and improved manufacturing efficiency.

Mechanical and Physical Properties Analysis

Metallocene polyethylene exhibits superior mechanical properties compared to conventional polyethylene, including enhanced tensile strength, improved impact resistance, and greater flexibility. Its uniform molecular weight distribution and precise polymer chain architecture result in better clarity and higher stiffness, optimizing physical performance for demanding applications. Conventional polyethylene typically shows broader molecular weight distribution, leading to variable mechanical strength and lower resistance to stress cracking.

Advantages of Metallocene Polyethylene

Metallocene polyethylene offers superior clarity, enhanced toughness, and improved sealability compared to conventional polyethylene due to its uniform molecular structure and narrow molecular weight distribution. It provides better impact resistance and tensile strength, making it ideal for high-performance applications such as flexible packaging and medical films. The precise control over polymer architecture in metallocene polyethylene results in consistent product quality and improved processability.

Limitations and Challenges of Metallocene Polyethylene

Metallocene polyethylene offers improved clarity and flexibility compared to conventional polyethylene but faces challenges such as higher production costs and limited availability of specialized catalysts. Its narrow molecular weight distribution can lead to processing difficulties, requiring precise control during manufacturing. Additionally, metallocene polyethylene may exhibit lower environmental stress crack resistance, posing limitations in certain high-performance applications.

Cost and Market Availability Comparison

Metallocene polyethylene typically incurs higher production costs due to advanced catalyst technology, resulting in a premium price compared to conventional polyethylene. Market availability of conventional polyethylene is substantially larger, driven by established production infrastructure and widespread applications. Pricing strategies and supply chains favor conventional polyethylene for mass-market use, while metallocene polyethylene occupies niche markets requiring superior material properties.

Choosing the Right Polyethylene for Your Application

Metallocene polyethylene offers superior clarity, flexibility, and consistent molecular weight distribution compared to conventional polyethylene, making it ideal for high-performance packaging and barrier applications. Conventional polyethylene, including LDPE and HDPE, provides cost-effective options with excellent chemical resistance and mechanical strength suitable for general-purpose containers and films. Selecting the right polyethylene depends on factors such as desired mechanical properties, transparency, barrier requirements, and budget constraints tied to specific industrial or consumer applications.

Metallocene Polyethylene vs Conventional Polyethylene Infographic

materialdif.com

materialdif.com