Polyethylene shrink film tightens when exposed to heat, providing a secure, tamper-evident seal ideal for packaging irregularly shaped items. In contrast, polyethylene stretch film relies on its elasticity and adhesive properties to cling tightly around objects, offering flexibility and protection mainly for pallet load stabilization. Choosing between shrink film and stretch film depends on the specific application, desired product presentation, and environmental conditions.

Table of Comparison

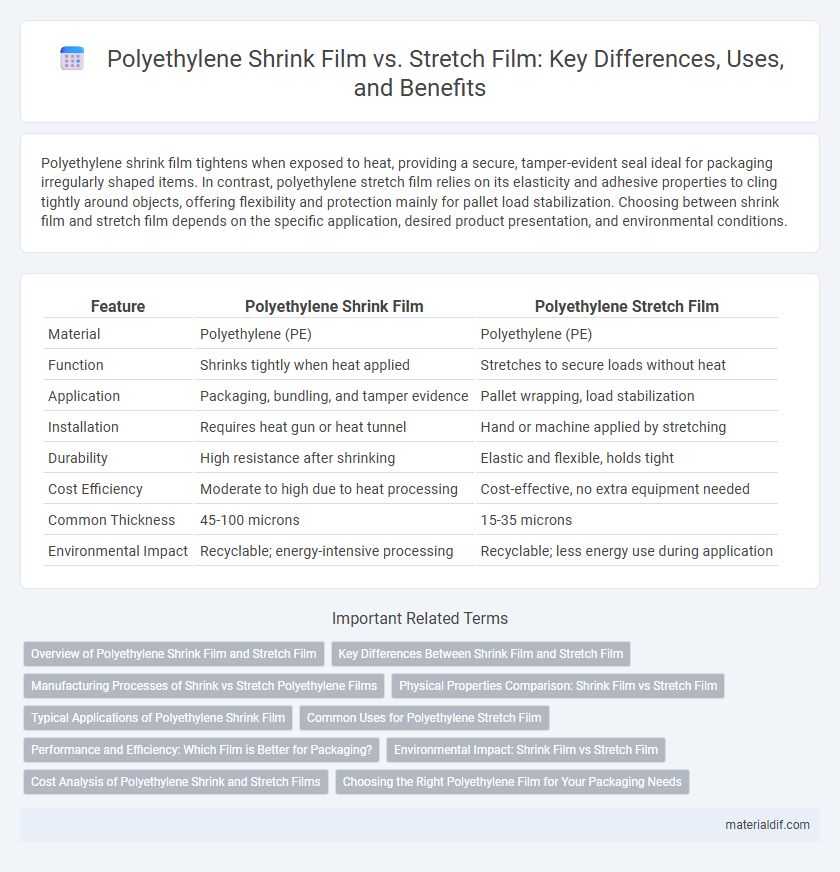

| Feature | Polyethylene Shrink Film | Polyethylene Stretch Film |

|---|---|---|

| Material | Polyethylene (PE) | Polyethylene (PE) |

| Function | Shrinks tightly when heat applied | Stretches to secure loads without heat |

| Application | Packaging, bundling, and tamper evidence | Pallet wrapping, load stabilization |

| Installation | Requires heat gun or heat tunnel | Hand or machine applied by stretching |

| Durability | High resistance after shrinking | Elastic and flexible, holds tight |

| Cost Efficiency | Moderate to high due to heat processing | Cost-effective, no extra equipment needed |

| Common Thickness | 45-100 microns | 15-35 microns |

| Environmental Impact | Recyclable; energy-intensive processing | Recyclable; less energy use during application |

Overview of Polyethylene Shrink Film and Stretch Film

Polyethylene shrink film is a type of plastic film that tightly contracts when heat is applied, providing secure packaging and protection for various products. In contrast, polyethylene stretch film is an elastic material designed to wrap around items by stretching, offering stability and containment without the need for heat. Both films are widely used in shipping and storage, with shrink film excelling in tamper resistance and stretch film being ideal for palletizing and load stabilization.

Key Differences Between Shrink Film and Stretch Film

Polyethylene shrink film and stretch film differ primarily in application and properties; shrink film contracts tightly when heated to conform to the shape of the product, offering superior protection and tamper evidence, while stretch film relies on elasticity to cling tightly around items without heat, providing flexibility and ease of use for palletizing. Shrink film typically has higher gauge thickness and is used in packaging where secure, rigid wrapping is necessary, whereas stretch film is thinner and designed for load stability during transport. The choice between shrink and stretch film depends on packaging requirements, including product shape, protection level, and cost considerations.

Manufacturing Processes of Shrink vs Stretch Polyethylene Films

Polyethylene shrink film is typically manufactured through a blown or cast extrusion process that incorporates orientation and heat treatment to enable the film to shrink upon heating. Stretch polyethylene film undergoes a blown or cast extrusion followed by mechanical stretching, either in the machine direction (MD) or transverse direction (TD), to impart elasticity and recovery properties. The key distinction lies in the post-extrusion processing--shrink film is heat-set to retain shrinkable characteristics, whereas stretch film is mechanically elongated to develop stretchability.

Physical Properties Comparison: Shrink Film vs Stretch Film

Polyethylene shrink film exhibits high clarity and excellent conformability, allowing it to tightly encase products upon heat application, while stretch film offers superior elongation and elasticity, providing secure load stability through its ability to stretch up to 300%. Shrink film typically has a higher thickness range, between 20 to 150 microns, resulting in increased puncture resistance, whereas stretch film ranges from 8 to 50 microns, optimizing flexibility and cost-effectiveness. Both films utilize low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE), but shrink film is designed for heat-induced fitting, contrasting with the mechanical stretch properties that characterize stretch film.

Typical Applications of Polyethylene Shrink Film

Polyethylene shrink film is commonly used for tamper-evident packaging, bundling multiple items for retail display, and securing products during transportation due to its ability to conform tightly when heat is applied. This type of film provides excellent protection against dust, moisture, and damage, making it ideal for packaging bottled beverages, food trays, and multipacks. Unlike stretch film, shrink film offers a rigid wrap that maintains product integrity and enhances shelf appeal through a clear, smooth finish.

Common Uses for Polyethylene Stretch Film

Polyethylene stretch film is widely used for pallet wrapping, securing goods during transportation, and bundling multiple items together due to its high elasticity and cling properties. It provides excellent protection from dust, moisture, and tampering while maintaining load stability on pallets in warehouses and distribution centers. Common industries utilizing polyethylene stretch film include food and beverage, pharmaceuticals, and manufacturing for efficient and cost-effective packaging solutions.

Performance and Efficiency: Which Film is Better for Packaging?

Polyethylene shrink film provides superior protection by tightly conforming to irregularly shaped products when heat is applied, ensuring maximum stability and tamper resistance during transport. In contrast, polyethylene stretch film offers excellent elasticity and cling, making it ideal for wrapping pallets quickly without heat, improving application speed and reducing energy consumption. For packaging efficiency, shrink film excels in secure containment and protection, while stretch film delivers cost-effective, flexible load stabilization with faster throughput.

Environmental Impact: Shrink Film vs Stretch Film

Polyethylene shrink film typically requires heat to activate its shrinking properties, leading to higher energy consumption during application compared to stretch film, which relies on elasticity and manual tension. Both films contribute to plastic waste, but stretch film's lower material usage and ease of recycling offer a comparatively reduced environmental footprint. Advanced developments in biodegradable and recyclable polyethylene stretch films further enhance sustainability by minimizing landfill accumulation and promoting circular economy practices.

Cost Analysis of Polyethylene Shrink and Stretch Films

Polyethylene shrink film generally incurs higher initial costs due to its specialized heat-activated properties and equipment requirements, but it offers superior product protection and containment, reducing damage-related expenses. In contrast, polyethylene stretch film is more cost-effective upfront, with flexible application processes and lower energy consumption, making it ideal for moderate protection needs. Evaluating total cost of ownership, businesses often find stretch film preferable for volume packaging, while shrink film justifies its expense in high-value or irregularly shaped products requiring tighter seals.

Choosing the Right Polyethylene Film for Your Packaging Needs

Polyethylene shrink film offers tight, secure packaging by shrinking firmly around products when heat is applied, providing excellent protection and tamper resistance. Polyethylene stretch film, however, stretches and clings to items without heat, making it ideal for bundling and stabilizing pallet loads with flexibility. Selecting the right film depends on your packaging requirements: opt for shrink film for a more rigid, durable seal and stretch film for versatile, cost-effective load containment.

Polyethylene Shrink Film vs Polyethylene Stretch Film Infographic

materialdif.com

materialdif.com