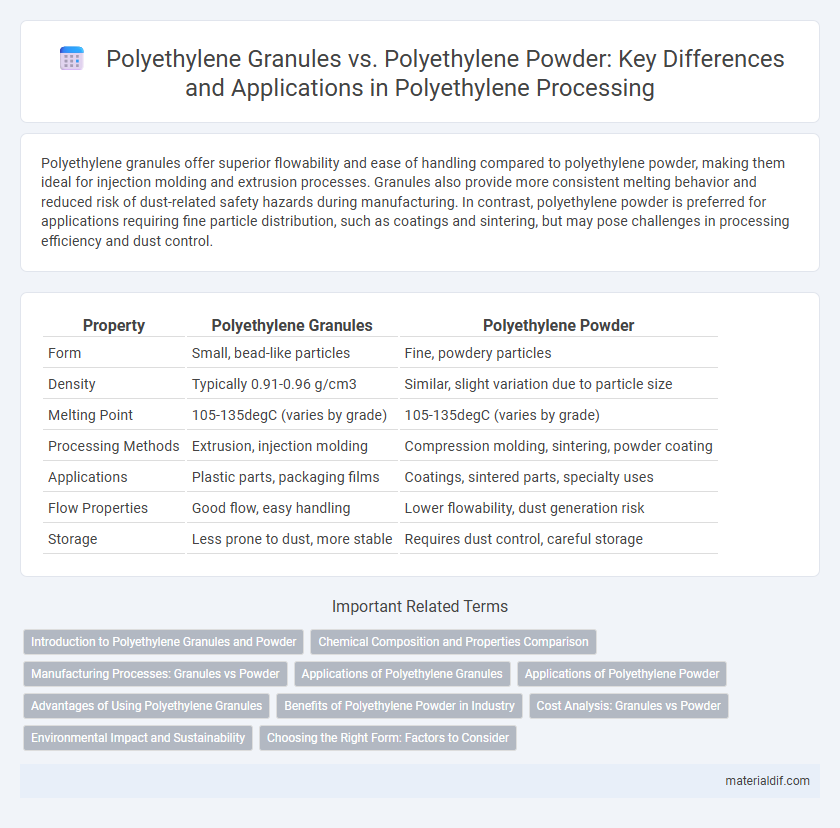

Polyethylene granules offer superior flowability and ease of handling compared to polyethylene powder, making them ideal for injection molding and extrusion processes. Granules also provide more consistent melting behavior and reduced risk of dust-related safety hazards during manufacturing. In contrast, polyethylene powder is preferred for applications requiring fine particle distribution, such as coatings and sintering, but may pose challenges in processing efficiency and dust control.

Table of Comparison

| Property | Polyethylene Granules | Polyethylene Powder |

|---|---|---|

| Form | Small, bead-like particles | Fine, powdery particles |

| Density | Typically 0.91-0.96 g/cm3 | Similar, slight variation due to particle size |

| Melting Point | 105-135degC (varies by grade) | 105-135degC (varies by grade) |

| Processing Methods | Extrusion, injection molding | Compression molding, sintering, powder coating |

| Applications | Plastic parts, packaging films | Coatings, sintered parts, specialty uses |

| Flow Properties | Good flow, easy handling | Lower flowability, dust generation risk |

| Storage | Less prone to dust, more stable | Requires dust control, careful storage |

Introduction to Polyethylene Granules and Powder

Polyethylene granules and powder are two primary forms of polyethylene used in various industrial applications, differing mainly in particle size and processing methods. Granules typically offer better flow properties and ease of handling during extrusion and molding processes, while powder is preferred for coating applications and sintering due to its fine particle size. Understanding these differences is crucial for selecting the appropriate polyethylene form based on specific manufacturing requirements and product performance.

Chemical Composition and Properties Comparison

Polyethylene granules and polyethylene powder both consist primarily of long-chain hydrocarbons with a repeating ethylene monomer (C2H4), offering similar chemical compositions but differing in physical form and particle size. Granules exhibit larger, uniform particles that enhance melt flow and processing stability, while powder features fine particles that improve surface area and molding precision. Variations in particle size influence properties like density, melting point, and mechanical strength, making granules ideal for extrusion and powder suited for sintering or coating applications.

Manufacturing Processes: Granules vs Powder

Polyethylene granules are produced through polymerization processes that yield uniform, pellet-shaped particles ideal for extrusion and injection molding. In contrast, polyethylene powder results from low-temperature polymerization or dispersion methods, offering finer particle size suited for sintering and rotational molding. The choice between granules and powder directly impacts manufacturing efficiency, processing techniques, and final product properties in polyethylene fabrication.

Applications of Polyethylene Granules

Polyethylene granules are widely used in industrial applications such as injection molding, blow molding, and extrusion processes, providing versatility in manufacturing automotive parts, packaging films, and containers. The granular form ensures efficient melting and consistent flow during processing, making it ideal for producing high-strength and durable plastic products. Compared to polyethylene powder, granules offer better handling, reduced dust generation, and improved process control in large-scale plastic fabrication.

Applications of Polyethylene Powder

Polyethylene powder is widely used in rotational molding, sintering, and coating applications due to its fine particle size and uniform melting properties, enabling the production of seamless and durable products such as tanks, containers, and automotive components. Unlike polyethylene granules, powder form offers enhanced surface finish and better control over layer thickness, which is crucial for high-performance coatings and adhesives. Its versatility also extends to biomedical and food packaging applications where precise control over melt and flow characteristics is essential.

Advantages of Using Polyethylene Granules

Polyethylene granules offer superior flowability and easier handling compared to polyethylene powder, enhancing efficiency in processing and manufacturing. Their consistent particle size reduces dust generation, minimizing health hazards and contamination risks in production environments. These granules enable better melting control and uniformity, resulting in higher-quality end products with improved mechanical properties.

Benefits of Polyethylene Powder in Industry

Polyethylene powder offers superior versatility in industrial applications such as rotational molding, coatings, and additive manufacturing due to its fine particle size and uniform distribution. Its enhanced flow properties and surface area improve blending and sintering processes compared to polyethylene granules. This results in higher precision, better product consistency, and increased efficiency in manufacturing complex or detailed plastic components.

Cost Analysis: Granules vs Powder

Polyethylene granules generally offer a lower cost per unit due to their ease of handling, reduced dust generation, and minimal processing requirements compared to polyethylene powder. Powder form demands specialized equipment for safe handling and processing, leading to increased operational costs and potential material waste. Cost efficiency in production often favors granules for large-scale manufacturing, while powder may be chosen for applications requiring finer particle size despite higher expenses.

Environmental Impact and Sustainability

Polyethylene granules generally have a lower environmental impact compared to polyethylene powder due to reduced dust emissions during manufacturing and handling, which minimizes air pollution and worker health risks. The granule form allows for more efficient recycling processes, contributing to better sustainability outcomes by facilitating material reuse and reducing landfill waste. In contrast, polyethylene powder often requires additional processing steps that increase energy consumption and carbon footprint, making granules a preferable choice for eco-conscious applications.

Choosing the Right Form: Factors to Consider

Polyethylene granules offer better flowability and ease of handling, making them ideal for injection molding and extrusion processes, while polyethylene powder provides finer particle size suited for sintering and rotational molding applications. Factors such as desired surface finish, melting behavior, processing equipment compatibility, and end-product specifications should determine the choice between granules and powder forms. Understanding the thermal properties, bulk density, and moisture content of each form ensures optimal performance in manufacturing workflows.

Polyethylene granules vs Polyethylene powder Infographic

materialdif.com

materialdif.com