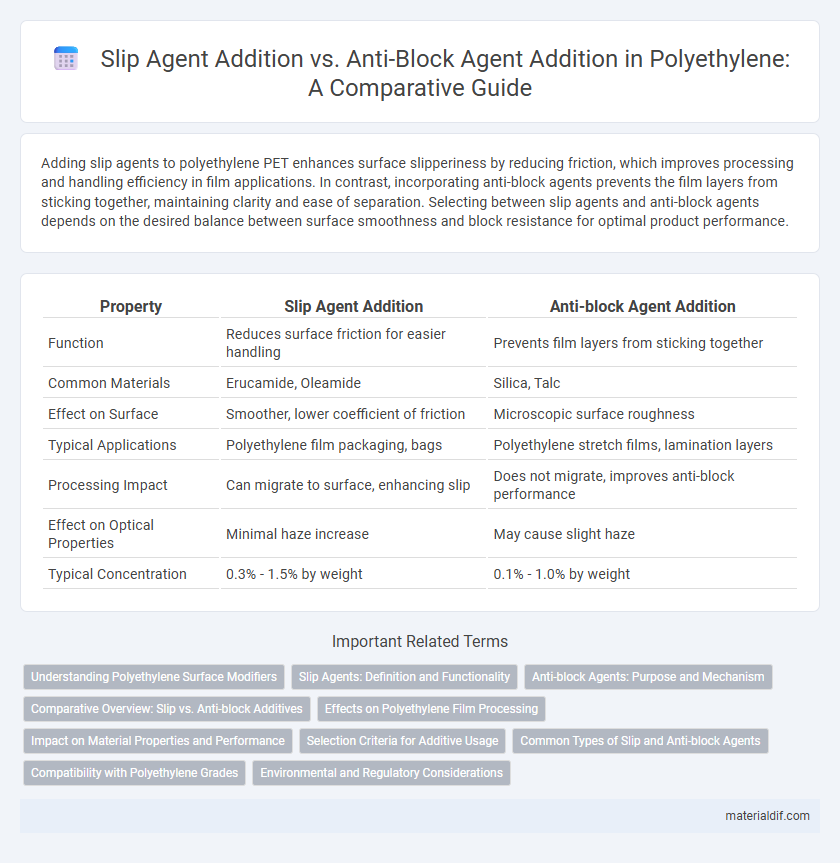

Adding slip agents to polyethylene PET enhances surface slipperiness by reducing friction, which improves processing and handling efficiency in film applications. In contrast, incorporating anti-block agents prevents the film layers from sticking together, maintaining clarity and ease of separation. Selecting between slip agents and anti-block agents depends on the desired balance between surface smoothness and block resistance for optimal product performance.

Table of Comparison

| Property | Slip Agent Addition | Anti-block Agent Addition |

|---|---|---|

| Function | Reduces surface friction for easier handling | Prevents film layers from sticking together |

| Common Materials | Erucamide, Oleamide | Silica, Talc |

| Effect on Surface | Smoother, lower coefficient of friction | Microscopic surface roughness |

| Typical Applications | Polyethylene film packaging, bags | Polyethylene stretch films, lamination layers |

| Processing Impact | Can migrate to surface, enhancing slip | Does not migrate, improves anti-block performance |

| Effect on Optical Properties | Minimal haze increase | May cause slight haze |

| Typical Concentration | 0.3% - 1.5% by weight | 0.1% - 1.0% by weight |

Understanding Polyethylene Surface Modifiers

Slip agents and anti-block agents both improve polyethylene surface properties by reducing friction and preventing film layers from sticking together. Slip agents, typically fatty acid amides like erucamide, migrate to the surface to create a lubricating layer that enhances processability and handling. Anti-block agents, such as silica or talc, act as microscopic spacers embedded in the polymer matrix, increasing surface roughness to minimize adhesion between film layers.

Slip Agents: Definition and Functionality

Slip agents are additives used in polyethylene to reduce surface friction, enhancing the processing and handling of plastic films by facilitating easier separation and smoother surface feel. They migrate to the film surface, creating a microscopic lubricating layer that improves slip properties without compromising clarity or mechanical strength. Unlike anti-block agents, which primarily prevent film layers from sticking together, slip agents focus on reducing resistance and improving film conveyance during manufacturing and end-use.

Anti-block Agents: Purpose and Mechanism

Anti-block agents in polyethylene are added to reduce surface tackiness and prevent films or sheets from sticking together, enhancing processability and end-use handling. These agents function by creating microscopic surface irregularities that reduce contact area and friction between layers, promoting smooth separation. Common anti-block additives include silica, talc, and calcium carbonate, which improve material flow without compromising clarity.

Comparative Overview: Slip vs. Anti-block Additives

Slip agents and anti-block agents serve distinct functions in polyethylene films: slip agents reduce surface friction to enhance processing and handling, while anti-block agents prevent film layers from sticking together by creating micro-roughness. Slip agents like erucamide migrate to the surface, improving lubricity and preventing scratches, whereas anti-block agents such as silica or talc remain dispersed within the polymer matrix to maintain film separation. Selecting the appropriate additive depends on the desired balance between clarity, mechanical properties, and surface behavior in polyethylene applications.

Effects on Polyethylene Film Processing

Slip agent addition in polyethylene film processing reduces friction between film layers, enhancing unwind tension and improving machinability during high-speed extrusion processes. Anti-block agent addition increases surface roughness, minimizing film sticking and facilitating smoother winding and handling in post-extrusion stages. Optimizing the balance between slip and anti-block agents is critical for maintaining film clarity and mechanical strength while ensuring efficient production and packaging performance.

Impact on Material Properties and Performance

Adding slip agents to polyethylene reduces the coefficient of friction on the film surface, enhancing processability and handling during converting operations. Anti-block agents create micro-roughness that prevents film layers from sticking together, improving unwind and packaging performance without significantly affecting transparency. Balancing slip and anti-block additives is crucial as excess slip agents may reduce surface strength, while excess anti-blocks can decrease clarity and surface smoothness.

Selection Criteria for Additive Usage

Slip agent addition in polyethylene is selected primarily to enhance surface lubrication, reduce coefficient of friction, and improve processing efficiency, making it ideal for applications requiring easy handling and reduced sticking. Anti-block agent addition is chosen to prevent film layers from adhering to each other, ensuring clear separation, maintaining transparency, and preserving mechanical properties during storage and use. Selection criteria depend on desired end-use properties, such as slip performance for packaging films or anti-block characteristics for multilayer films, balanced against factors like additive compatibility, concentration, and processing conditions.

Common Types of Slip and Anti-block Agents

Common types of slip agents for polyethylene include erucamide, oleamide, and stearamide, which reduce friction and improve surface slip properties. Anti-block agents commonly used are silica, talc, and calcium carbonate, which prevent film layers from sticking together by creating microscopic surface roughness. Choosing the appropriate slip or anti-block agent depends on the desired balance between surface smoothness and anti-block performance in polyethylene applications.

Compatibility with Polyethylene Grades

Slip agents like erucamide exhibit excellent compatibility with low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE), enhancing surface lubrication without compromising clarity or mechanical properties. Anti-block agents such as silica or talc are effective in high-density polyethylene (HDPE) and medium-density polyethylene (MDPE), improving film separation and processing performance while maintaining polymer integrity. Selecting the appropriate additive depends on the polyethylene grade to optimize film performance and processing behavior.

Environmental and Regulatory Considerations

Slip agents in polyethylene, primarily amides or fatty acid derivatives, improve surface lubrication but may raise environmental concerns due to potential migration and biodegradability issues, prompting regulatory scrutiny under REACH and FDA standards. Anti-block agents, often mineral-based like silica or talc, enhance surface separation without significant migration risks, generally facing fewer regulatory restrictions related to toxicity or environmental persistence. The selection between slip and anti-block additives demands careful evaluation of their ecological impact and compliance with evolving global regulations to ensure sustainable polyethylene product performance.

Slip agent addition vs Anti-block agent addition Infographic

materialdif.com

materialdif.com