Metallocene polyethylene offers superior clarity, uniformity, and enhanced mechanical properties compared to Ziegler-Natta polyethylene due to its precise molecular control during polymerization. Ziegler-Natta polyethylene typically exhibits broader molecular weight distribution and less consistent morphology, resulting in varied performance characteristics. The advanced catalyst system of metallocenes enables tailored polymer structures, making it ideal for high-performance packaging and film applications.

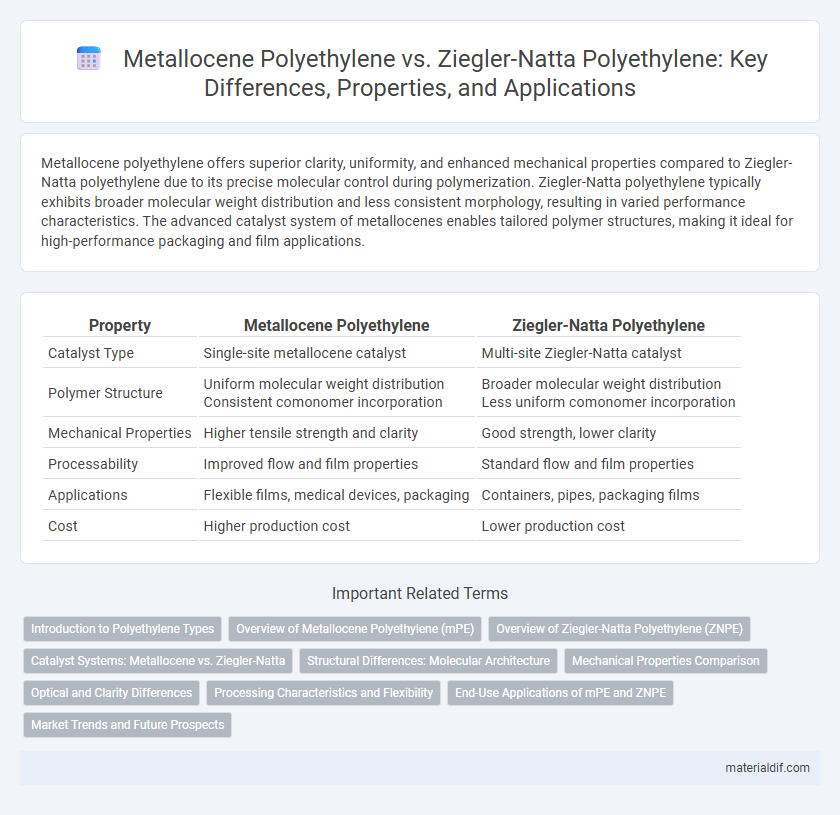

Table of Comparison

| Property | Metallocene Polyethylene | Ziegler-Natta Polyethylene |

|---|---|---|

| Catalyst Type | Single-site metallocene catalyst | Multi-site Ziegler-Natta catalyst |

| Polymer Structure | Uniform molecular weight distribution Consistent comonomer incorporation |

Broader molecular weight distribution Less uniform comonomer incorporation |

| Mechanical Properties | Higher tensile strength and clarity | Good strength, lower clarity |

| Processability | Improved flow and film properties | Standard flow and film properties |

| Applications | Flexible films, medical devices, packaging | Containers, pipes, packaging films |

| Cost | Higher production cost | Lower production cost |

Introduction to Polyethylene Types

Metallocene polyethylene is produced using single-site catalysts, offering superior uniformity, clarity, and mechanical properties compared to Ziegler-Natta polyethylene, which is synthesized through heterogeneous multi-site catalysts. Ziegler-Natta polyethylene remains widely used for general applications due to cost-effectiveness and established production methods. Differences in catalyst technology significantly impact polymer structure, molecular weight distribution, and end-use performance of polyethylene products.

Overview of Metallocene Polyethylene (mPE)

Metallocene Polyethylene (mPE) is produced using metallocene catalysts, resulting in a polymer with uniform molecular weight distribution and enhanced chain branching control. This precise polymer architecture enhances clarity, toughness, and sealability compared to traditional Ziegler-Natta polyethylene. mPE is widely applied in flexible packaging films, healthcare products, and wire insulation due to its superior optical and mechanical properties.

Overview of Ziegler-Natta Polyethylene (ZNPE)

Ziegler-Natta Polyethylene (ZNPE) is produced using traditional Ziegler-Natta catalysts, which facilitate stereoregular polymerization, resulting in high-density polyethylene with controlled molecular weight distribution. This type of polyethylene exhibits excellent mechanical properties, chemical resistance, and processability, making it widely used in packaging, automotive parts, and consumer goods. ZNPE offers a cost-effective solution with consistent performance, preferred in large-scale industrial applications compared to other catalyst-derived polyethylenes.

Catalyst Systems: Metallocene vs. Ziegler-Natta

Metallocene polyethylene utilizes single-site catalysts that provide precise control over polymer chain structure, resulting in uniform molecular weight distribution and enhanced material properties. Ziegler-Natta polyethylene relies on multi-site catalysts, producing polymers with broader molecular weight distribution and less structural uniformity. The tailored active sites of metallocene catalysts enable improved clarity, strength, and flexibility compared to the traditional Ziegler-Natta catalyst systems.

Structural Differences: Molecular Architecture

Metallocene polyethylene features a uniform molecular architecture with narrow molecular weight distribution, resulting from single-site catalytic polymerization, whereas Ziegler-Natta polyethylene exhibits broader molecular weight distribution and more heterogeneous branching due to multi-site catalysis. Metallocene catalysts enable precise control over polymer chain structure, producing highly isotactic or syndiotactic configurations, enhancing mechanical and optical properties. In contrast, Ziegler-Natta catalysts generate polymers with varied chain lengths and branching patterns, affecting crystallinity and density.

Mechanical Properties Comparison

Metallocene polyethylene exhibits superior mechanical properties compared to Ziegler-Natta polyethylene due to its uniform molecular weight distribution and precise branching control, which enhances tensile strength and impact resistance. Ziegler-Natta polyethylene typically shows broader molecular weight distribution, resulting in less consistent mechanical performance but often higher processability for certain applications. The enhanced clarity and toughness of metallocene polyethylene make it ideal for applications demanding precise mechanical reliability and durability.

Optical and Clarity Differences

Metallocene polyethylene exhibits superior optical properties compared to Ziegler-Natta polyethylene, with higher clarity and gloss due to its uniform molecular structure and narrower molecular weight distribution. The enhanced transparency of metallocene polyethylene results from fewer branching irregularities and a more consistent polymer chain arrangement. In contrast, Ziegler-Natta polyethylene often has a broader molecular weight distribution, causing increased opacity and a more hazy appearance in films and products.

Processing Characteristics and Flexibility

Metallocene polyethylene offers superior processing characteristics with enhanced control over polymer chain distribution, resulting in improved consistency and easier melt processing compared to Ziegler-Natta polyethylene. Its molecular uniformity provides greater flexibility and elasticity, making it ideal for applications requiring high tensile strength and impact resistance. Ziegler-Natta polyethylene tends to have broader molecular weight distribution, which limits its flexibility but offers robustness for standard extrusion and molding processes.

End-Use Applications of mPE and ZNPE

Metallocene polyethylene (mPE) offers superior clarity, flexibility, and consistent molecular weight distribution, making it ideal for high-performance film applications such as food packaging, stretch films, and medical packaging. Ziegler-Natta polyethylene (ZNPE), known for its cost-effectiveness and robust mechanical properties, is widely used in pipes, containers, and durable goods where strength and toughness are critical. The precise molecular architecture of mPE enables enhanced sealing and gloss, while ZNPE provides reliable performance in structural and heavy-duty applications.

Market Trends and Future Prospects

Metallocene polyethylene offers superior clarity, flexibility, and uniform molecular structure compared to Ziegler-Natta polyethylene, driving higher demand in premium packaging markets. The global metallocene polyethylene market is projected to grow at a CAGR of over 7% through 2030, fueled by increased adoption in medical, automotive, and consumer goods industries. Innovations in catalyst technology and sustainability trends are expected to further enhance metallocene polyethylene's market share, while Ziegler-Natta remains dominant in large-scale commodity applications.

Metallocene Polyethylene vs Ziegler-Natta Polyethylene Infographic

materialdif.com

materialdif.com