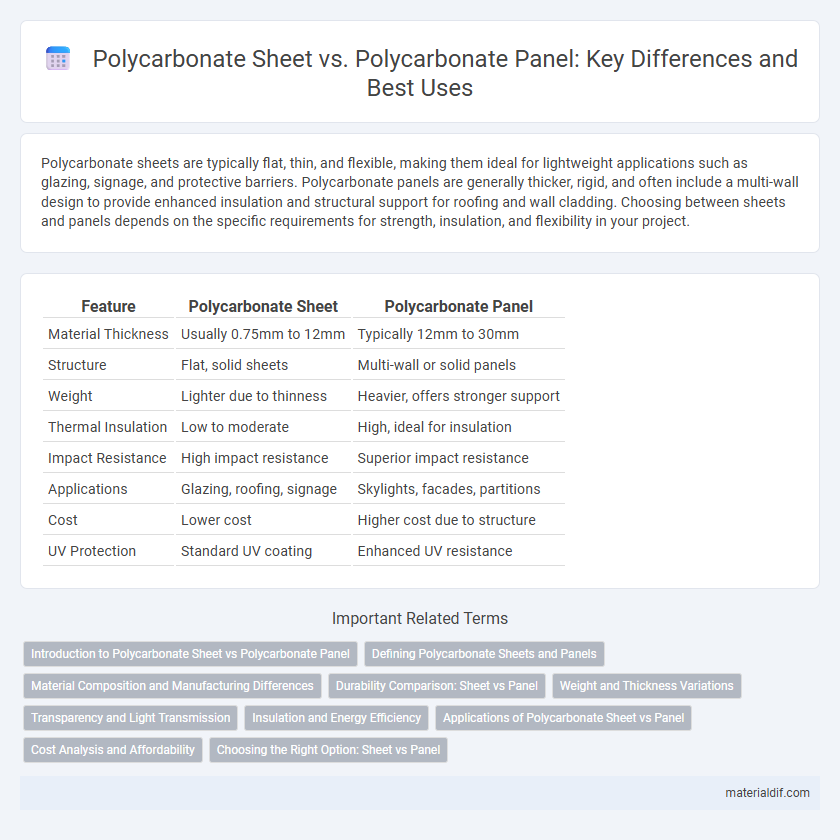

Polycarbonate sheets are typically flat, thin, and flexible, making them ideal for lightweight applications such as glazing, signage, and protective barriers. Polycarbonate panels are generally thicker, rigid, and often include a multi-wall design to provide enhanced insulation and structural support for roofing and wall cladding. Choosing between sheets and panels depends on the specific requirements for strength, insulation, and flexibility in your project.

Table of Comparison

| Feature | Polycarbonate Sheet | Polycarbonate Panel |

|---|---|---|

| Material Thickness | Usually 0.75mm to 12mm | Typically 12mm to 30mm |

| Structure | Flat, solid sheets | Multi-wall or solid panels |

| Weight | Lighter due to thinness | Heavier, offers stronger support |

| Thermal Insulation | Low to moderate | High, ideal for insulation |

| Impact Resistance | High impact resistance | Superior impact resistance |

| Applications | Glazing, roofing, signage | Skylights, facades, partitions |

| Cost | Lower cost | Higher cost due to structure |

| UV Protection | Standard UV coating | Enhanced UV resistance |

Introduction to Polycarbonate Sheet vs Polycarbonate Panel

Polycarbonate sheets are thin, flexible thermoplastic materials used for glazing, roofing, and protective covers, offering high impact resistance and transparency. Polycarbonate panels are thicker, often multi-layered structures designed for enhanced insulation, durability, and structural applications in construction and industrial projects. Both materials provide exceptional strength and lightweight properties but differ in form, thickness, and application suitability.

Defining Polycarbonate Sheets and Panels

Polycarbonate sheets are flat, thin materials primarily used for glazing, roofing, and protective barriers due to their lightweight and high-impact resistance. Polycarbonate panels, often thicker and rigid, are designed for structural applications requiring enhanced durability and thermal insulation. Both forms utilize the same polycarbonate resin but differ in thickness, rigidity, and intended usage in construction and industrial projects.

Material Composition and Manufacturing Differences

Polycarbonate sheets are typically produced through extrusion, resulting in continuous, uniform thickness ideal for large, flat surfaces, while polycarbonate panels are often made via compression or injection molding, enabling varied shapes and thicknesses with enhanced structural properties. The material composition of sheets predominantly consists of pure polycarbonate resin, ensuring clarity and impact resistance, whereas panels may incorporate additives or layered composites to improve thermal insulation, fire resistance, or rigidity. These manufacturing and compositional differences influence the application suitability, with sheets preferred for glazing and panels favored in construction and design requiring customized forms and reinforced performance.

Durability Comparison: Sheet vs Panel

Polycarbonate sheets exhibit superior impact resistance and flexibility compared to polycarbonate panels, making them highly durable for environments prone to mechanical stress. Panels, often composed of multiple laminated sheets, provide enhanced structural strength and rigidity but may be more prone to delamination under extreme conditions. The choice between sheet versus panel depends on the specific durability requirements, with sheets favored for impact resilience and panels for load-bearing applications.

Weight and Thickness Variations

Polycarbonate sheets typically offer greater thickness versatility, ranging from 0.75 mm to 12 mm, allowing for precise customization in various applications. In comparison, polycarbonate panels are generally thicker and heavier, often designed for structural uses with typical thicknesses starting around 6 mm, resulting in increased weight. The weight difference between sheets and panels significantly impacts handling and installation, with sheets being lighter and more manageable for lightweight projects.

Transparency and Light Transmission

Polycarbonate sheets typically offer higher transparency and superior light transmission, making them ideal for applications requiring clear visibility and natural lighting. Polycarbonate panels, while still transparent, often incorporate structural reinforcements or multilayer designs that can slightly reduce light transmission but increase durability and thermal insulation. Choosing between sheets and panels depends on balancing the need for maximum light clarity with strength and environmental resistance.

Insulation and Energy Efficiency

Polycarbonate sheets and panels both offer excellent insulation properties, but polycarbonate panels typically provide superior thermal resistance due to their multi-wall structure, which traps air between layers and reduces heat transfer. This design enhances energy efficiency by maintaining indoor temperature stability and reducing heating and cooling costs in buildings. Polycarbonate sheets, while slightly less insulative, remain popular for glazing and roofing applications due to their lightweight and UV resistance.

Applications of Polycarbonate Sheet vs Panel

Polycarbonate sheets are commonly used in applications requiring lightweight, transparent, and impact-resistant materials such as skylights, greenhouse glazing, and protective barriers. Polycarbonate panels, often thicker and with enhanced structural strength, are ideal for industrial roofing, wall cladding, and security enclosures where durability and insulation are critical. Both materials excel in UV resistance and weatherability, but sheets are preferred for aesthetic and lightweight solutions, whereas panels suit more heavy-duty, load-bearing applications.

Cost Analysis and Affordability

Polycarbonate sheets typically offer greater affordability compared to polycarbonate panels due to their simpler manufacturing process and lower material thickness, making them a cost-effective choice for budget-sensitive projects. Polycarbonate panels, often thicker and designed with multi-wall or reinforced structures, provide enhanced durability and insulation but come with a higher price point reflecting these added benefits. Choosing between the two depends on balancing upfront cost with long-term performance requirements, as sheets cater to economical needs while panels justify their investment through improved strength and thermal efficiency.

Choosing the Right Option: Sheet vs Panel

Polycarbonate sheets offer superior flexibility and ease of cutting, making them ideal for custom applications needing specific shapes or sizes. Polycarbonate panels provide enhanced structural integrity and are often pre-finished for quick installation in roofing or cladding projects. Selecting between polycarbonate sheet and panel depends on project requirements for durability, size customization, and installation speed.

Polycarbonate Sheet vs Polycarbonate Panel Infographic

materialdif.com

materialdif.com