Polycarbonate and Lexan are often used interchangeably, but Lexan is actually a brand name for a specific type of polycarbonate known for its superior impact resistance and transparency. Polycarbonate offers excellent durability, heat resistance, and clarity, making it ideal for applications ranging from eyewear lenses to automotive parts. Choosing between generic polycarbonate and Lexan depends on specific performance requirements and brand reliability in your project.

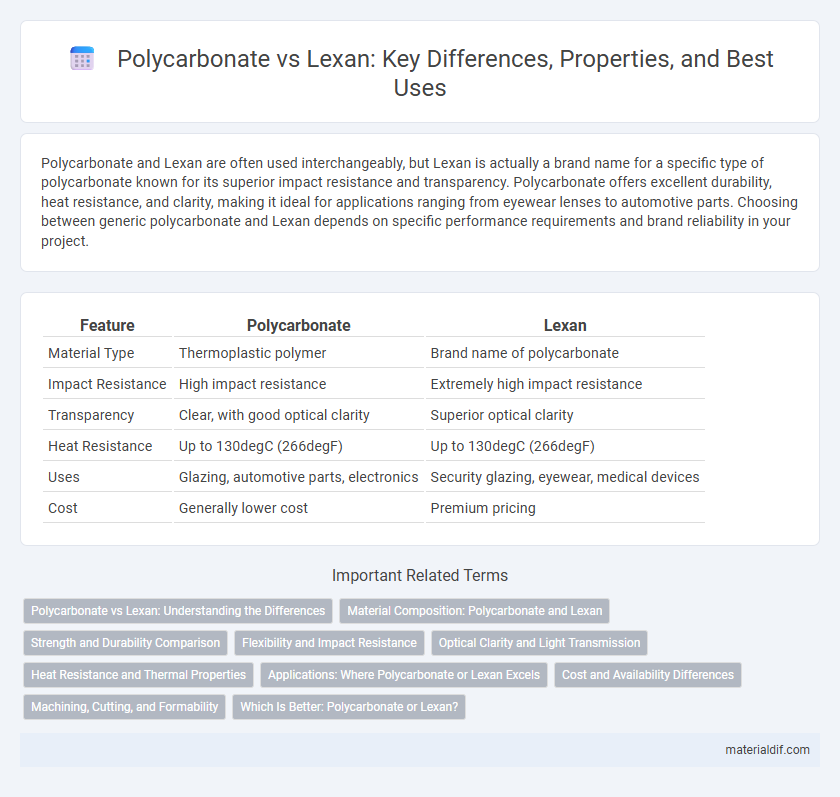

Table of Comparison

| Feature | Polycarbonate | Lexan |

|---|---|---|

| Material Type | Thermoplastic polymer | Brand name of polycarbonate |

| Impact Resistance | High impact resistance | Extremely high impact resistance |

| Transparency | Clear, with good optical clarity | Superior optical clarity |

| Heat Resistance | Up to 130degC (266degF) | Up to 130degC (266degF) |

| Uses | Glazing, automotive parts, electronics | Security glazing, eyewear, medical devices |

| Cost | Generally lower cost | Premium pricing |

Polycarbonate vs Lexan: Understanding the Differences

Polycarbonate and Lexan are often used interchangeably, but Lexan is actually a trademarked brand of polycarbonate resin known for its high impact resistance and optical clarity. Polycarbonate encompasses a broader category of thermoplastic polymers used in applications ranging from eyewear lenses to automotive components. Understanding these differences is essential for selecting the appropriate material based on specific performance requirements such as durability, UV resistance, and cost.

Material Composition: Polycarbonate and Lexan

Polycarbonate is a durable thermoplastic polymer characterized by its tough, transparent structure composed primarily of bisphenol A and phosgene. Lexan, a brand name for a specific polycarbonate resin produced by SABIC, shares the same chemical composition but is distinguished by proprietary additives that enhance impact resistance and UV stability. Both materials exhibit similar molecular structures, but Lexan's tailored formulation provides optimized performance for specific industrial applications.

Strength and Durability Comparison

Polycarbonate and Lexan both exhibit exceptional strength and durability, with Lexan being a proprietary brand of polycarbonate known for its superior impact resistance and toughness. Polycarbonate typically offers high tensile strength around 60 MPa and can withstand significant stress without cracking, while Lexan's engineered composition enhances its ability to endure extreme impacts and temperature variations. Both materials are widely used in safety applications, but Lexan's enhanced durability makes it a preferred choice for bulletproof glass and protective barriers.

Flexibility and Impact Resistance

Polycarbonate and Lexan are both highly durable thermoplastics known for exceptional impact resistance, with Lexan being a brand-specific type of polycarbonate. Lexan typically offers superior flexibility compared to generic polycarbonate variants, allowing it to withstand greater deformation without cracking. This combination of high impact resistance and enhanced flexibility makes Lexan ideal for applications requiring both toughness and resilience.

Optical Clarity and Light Transmission

Polycarbonate and Lexan both offer high optical clarity and excellent light transmission, with light transmission rates typically around 88-92%. Lexan, a brand of polycarbonate, often features enhanced optical properties due to proprietary manufacturing processes, resulting in superior clarity and minimal haze. Both materials are widely used in applications requiring transparency and durability, such as safety glazing and eyewear lenses.

Heat Resistance and Thermal Properties

Polycarbonate and Lexan share similar chemical compositions, but Lexan, a brand of polycarbonate, often exhibits higher heat resistance with a heat deflection temperature around 135degC (275degF) compared to general polycarbonate grades typically resisting up to 130degC (266degF). The thermal conductivity of Lexan is approximately 0.19 W/m*K, supporting effective heat dissipation in applications requiring thermal stability. Both materials maintain dimensional stability under thermal stress, but Lexan's proprietary additives enhance its performance in high-temperature environments.

Applications: Where Polycarbonate or Lexan Excels

Polycarbonate and Lexan both excel in applications requiring high impact resistance, transparency, and durability, such as protective eyewear, automotive components, and medical devices. Lexan, a branded polycarbonate resin, is preferred for security glazing and riot shields due to its superior clarity and toughness. Polycarbonate finds extensive use in electronics casings and construction materials where lightweight strength and UV resistance are critical.

Cost and Availability Differences

Polycarbonate and Lexan are often compared as they both offer high impact resistance and transparency, but Lexan generally commands a higher price due to its brand reputation and specialized formulations. Polycarbonate sheets are widely available from multiple manufacturers, leading to increased competition and lower costs, whereas Lexan, being a registered trademark of SABIC, may have limited distribution channels impacting availability. Cost differences between the two can range from 10-30%, with Polycarbonate typically preferred for budget-conscious projects requiring similar durability.

Machining, Cutting, and Formability

Polycarbonate and Lexan are both high-performance thermoplastics widely used in machining, cutting, and formability applications; Lexan is actually a brand name for a type of polycarbonate produced by SABIC. Polycarbonate offers excellent machinability with high impact resistance and thermal stability, making it suitable for precision cutting and complex forming processes like thermoforming and vacuum forming. Lexan polycarbonate sheets are preferred when superior clarity and UV resistance are required, maintaining formability while resisting cracking during intricate machining operations.

Which Is Better: Polycarbonate or Lexan?

Polycarbonate and Lexan are often compared because Lexan is a brand name of polycarbonate resin known for its superior impact resistance and clarity. Polycarbonate sheets provide excellent durability, UV resistance, and thermal stability, making them ideal for outdoor applications, but Lexan typically offers enhanced scratch resistance and can be easier to fabricate. Choosing between polycarbonate and Lexan depends on specific project requirements, with Lexan favored for high-performance uses due to its proven strength and versatility.

Polycarbonate vs Lexan Infographic

materialdif.com

materialdif.com