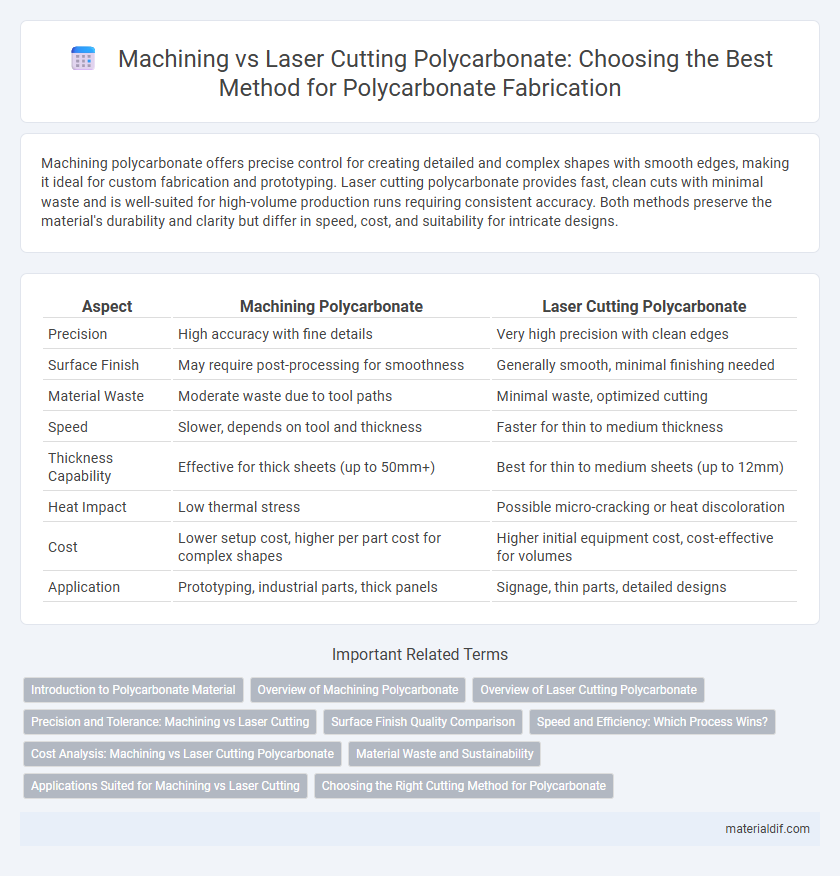

Machining polycarbonate offers precise control for creating detailed and complex shapes with smooth edges, making it ideal for custom fabrication and prototyping. Laser cutting polycarbonate provides fast, clean cuts with minimal waste and is well-suited for high-volume production runs requiring consistent accuracy. Both methods preserve the material's durability and clarity but differ in speed, cost, and suitability for intricate designs.

Table of Comparison

| Aspect | Machining Polycarbonate | Laser Cutting Polycarbonate |

|---|---|---|

| Precision | High accuracy with fine details | Very high precision with clean edges |

| Surface Finish | May require post-processing for smoothness | Generally smooth, minimal finishing needed |

| Material Waste | Moderate waste due to tool paths | Minimal waste, optimized cutting |

| Speed | Slower, depends on tool and thickness | Faster for thin to medium thickness |

| Thickness Capability | Effective for thick sheets (up to 50mm+) | Best for thin to medium sheets (up to 12mm) |

| Heat Impact | Low thermal stress | Possible micro-cracking or heat discoloration |

| Cost | Lower setup cost, higher per part cost for complex shapes | Higher initial equipment cost, cost-effective for volumes |

| Application | Prototyping, industrial parts, thick panels | Signage, thin parts, detailed designs |

Introduction to Polycarbonate Material

Polycarbonate is a durable, lightweight thermoplastic known for high impact resistance and excellent optical clarity, making it ideal for various industrial and commercial applications. Machining polycarbonate involves precise cutting and shaping using tools such as CNC mills or drills, maintaining material integrity and surface finish. Laser cutting polycarbonate offers fast, clean cuts with minimal thermal distortion, but requires careful control to avoid edge melting or discoloration.

Overview of Machining Polycarbonate

Machining polycarbonate involves using traditional tools such as routers, drills, and saws to shape the material with precise control over dimensions and surface finish. This method allows for complex geometries and fine detailing without compromising the polymer's strength and transparency. Machining polycarbonate typically produces less thermal stress compared to laser cutting, minimizing the risk of melting or discoloration.

Overview of Laser Cutting Polycarbonate

Laser cutting polycarbonate offers precise, high-speed processing with clean edges and minimal thermal distortion, making it ideal for detailed designs and intricate shapes. The process uses a focused laser beam to vaporize the material along the cutting path, ensuring accuracy and smooth finishes without mechanical stress. Compared to traditional machining methods, laser cutting reduces material waste and enhances production efficiency in polycarbonate fabrication.

Precision and Tolerance: Machining vs Laser Cutting

Machining polycarbonate provides superior precision and tighter tolerances, typically within +-0.005 inches, due to controlled mechanical cutting processes ideal for intricate and detailed parts. Laser cutting polycarbonate achieves good precision but often with slightly wider tolerances around +-0.01 inches, as heat-affected zones can cause minor warping or surface melting. For applications demanding exact dimensions and minimal post-processing, machining is the preferred method, while laser cutting suits faster, less critical tolerance requirements.

Surface Finish Quality Comparison

Machining polycarbonate typically results in a smoother surface finish with minimal thermal distortion, preserving clarity and dimensional accuracy. Laser cutting polycarbonate often produces a slightly rougher edge due to localized melting and recast material, which may require post-processing to enhance finish quality. Selecting machining over laser cutting is preferable for applications demanding high-precision surfaces and optical clarity.

Speed and Efficiency: Which Process Wins?

Machining polycarbonate often delivers precise and smooth edges but tends to be slower due to the need for physical tooling and careful handling to prevent melting or cracking. Laser cutting excels in speed by rapidly vaporizing material without physical contact, providing efficient and clean cuts ideal for complex shapes and high-volume production. For projects prioritizing quick turnaround and intricate designs, laser cutting generally outperforms machining in speed and overall efficiency.

Cost Analysis: Machining vs Laser Cutting Polycarbonate

Machining polycarbonate typically incurs higher labor and tooling costs due to the need for specialized equipment and skilled operators, especially for complex shapes or tight tolerances. Laser cutting polycarbonate offers greater precision and faster processing times, often reducing overall production expenses, but initial investment in laser machinery may be significant. Cost efficiency depends on production volume, with machining favoring low-quantity, custom orders, while laser cutting excels in high-volume, repetitive tasks.

Material Waste and Sustainability

Machining polycarbonate generates more material waste due to the subtractive process involving cutting and drilling, which produces offcuts and scrap that are often difficult to recycle. Laser cutting polycarbonate offers higher precision with minimal kerf, significantly reducing material waste and improving sustainability by enabling more efficient use of raw sheets. Choosing laser cutting over traditional machining supports sustainable manufacturing practices by decreasing waste production and conserving polycarbonate resources.

Applications Suited for Machining vs Laser Cutting

Machining polycarbonate is ideal for applications requiring high precision and complex three-dimensional shapes, such as prototypes, custom enclosures, and intricate mechanical components. Laser cutting polycarbonate excels in producing clean, detailed two-dimensional designs for signage, decorative panels, and electronic housings with tight tolerances. Machining suits thicker sheets and structural parts, while laser cutting is preferred for thinner materials and rapid production of flat components.

Choosing the Right Cutting Method for Polycarbonate

Machining polycarbonate offers precise control for complex shapes and produces smooth edges, ideal for applications requiring tight tolerances and mechanical strength. Laser cutting polycarbonate enables fast, clean cuts with minimal material stress, making it suitable for detailed designs and high-volume production. Choosing the right cutting method depends on factors such as project complexity, production volume, edge finish requirements, and budget constraints.

Machining Polycarbonate vs Laser Cutting Polycarbonate Infographic

materialdif.com

materialdif.com