Cold bending of polycarbonate PET involves shaping the material at room temperature, which minimizes the risk of surface damage but may cause internal stress and potential cracking. Hot bending, by heating the polycarbonate PET to a pliable temperature, allows for more precise and flexible shaping while reducing internal stress and maintaining structural integrity. Choosing between cold bending and hot bending depends on the complexity of the design and the performance requirements of the final product.

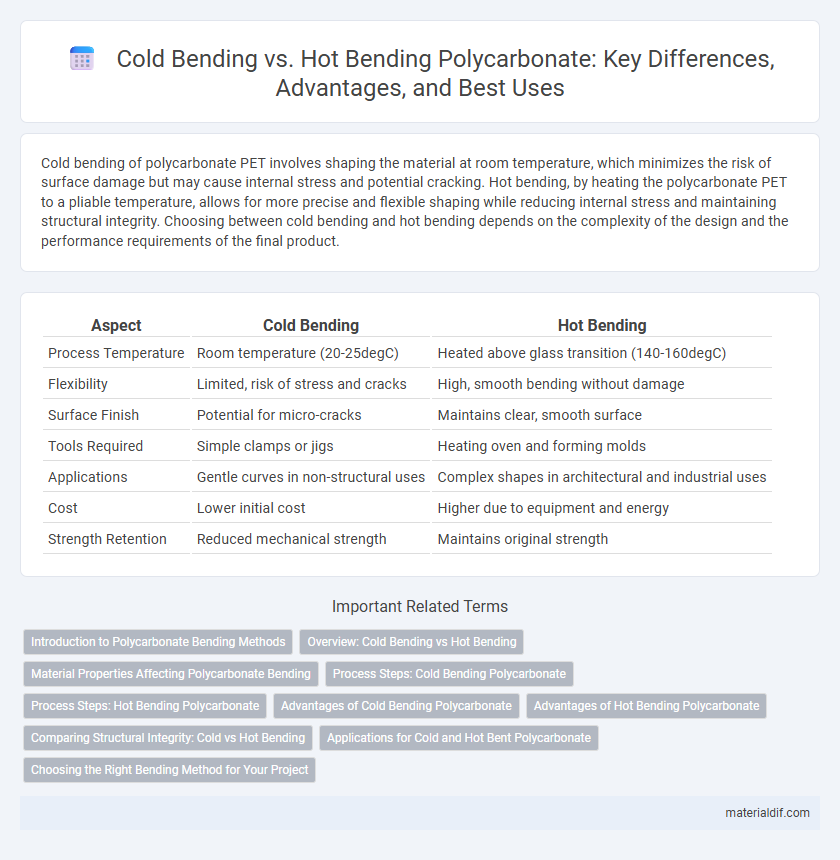

Table of Comparison

| Aspect | Cold Bending | Hot Bending |

|---|---|---|

| Process Temperature | Room temperature (20-25degC) | Heated above glass transition (140-160degC) |

| Flexibility | Limited, risk of stress and cracks | High, smooth bending without damage |

| Surface Finish | Potential for micro-cracks | Maintains clear, smooth surface |

| Tools Required | Simple clamps or jigs | Heating oven and forming molds |

| Applications | Gentle curves in non-structural uses | Complex shapes in architectural and industrial uses |

| Cost | Lower initial cost | Higher due to equipment and energy |

| Strength Retention | Reduced mechanical strength | Maintains original strength |

Introduction to Polycarbonate Bending Methods

Polycarbonate bending methods primarily include cold bending and hot bending, each suited for different applications based on material thickness and desired shape complexity. Cold bending involves flexing polycarbonate sheets at ambient temperature, typically used for gentle curves with minimal risk of surface deformation, while hot bending employs controlled heating to make the material pliable for sharper bends or intricate shapes. Understanding the mechanical properties and thermal behavior of polycarbonate is crucial for selecting an appropriate bending technique that ensures structural integrity and optimal performance.

Overview: Cold Bending vs Hot Bending

Cold bending polycarbonate involves shaping the material at ambient temperatures without heating, which is suitable for gentle curves but may induce internal stress and limited flexibility. Hot bending utilizes controlled heating to soften the polycarbonate, allowing for more complex shapes and reduced risk of cracking or distortion during the forming process. Selecting between cold and hot bending depends on factors such as the desired bend radius, thickness of the material, and the application's structural requirements.

Material Properties Affecting Polycarbonate Bending

Polycarbonate's high impact resistance and thermal stability allow it to withstand cold bending without cracking, provided the radius exceeds its minimum bend radius, typically 3-4 times its thickness. Hot bending leverages the material's glass transition temperature of around 147degC, making it pliable for tighter bends without compromising structural integrity. The key difference in bending methods is how temperature affects the polymer chains' flexibility, with heat enabling greater deformation while maintaining polycarbonate's clarity and strength.

Process Steps: Cold Bending Polycarbonate

Cold bending polycarbonate involves gradually applying mechanical force to shape the material without heating, preserving its structural integrity and surface finish. This process requires careful control of bending radius and speed to prevent stress fractures and maintain clarity. Compared to hot bending, cold bending reduces energy consumption and avoids thermal distortion, making it ideal for applications requiring precise dimensional stability.

Process Steps: Hot Bending Polycarbonate

Hot bending polycarbonate involves heating the material to a specific temperature range, typically between 140degC and 180degC, to increase its flexibility and prevent cracking. The process includes uniformly heating the polycarbonate sheet using an oven or infrared heater, followed by bending it over a form or mold to achieve the desired angle or curvature. Cooling the bent polycarbonate gradually ensures the shape is retained while maintaining its structural integrity and optical clarity.

Advantages of Cold Bending Polycarbonate

Cold bending polycarbonate offers significant advantages including reduced energy consumption and cost-efficiency since it does not require heating equipment. It preserves the material's structural integrity and optical clarity by minimizing thermal stress and discoloration. This method allows for quicker installation times and flexibility in on-site adjustments without compromising durability.

Advantages of Hot Bending Polycarbonate

Hot bending polycarbonate offers superior flexibility and precision, enabling complex shapes without compromising material strength. The uniform heat application reduces internal stress, enhancing durability and minimizing the risk of cracking or deformation. This method significantly improves the aesthetic quality and structural integrity of polycarbonate components used in architectural and industrial applications.

Comparing Structural Integrity: Cold vs Hot Bending

Cold bending polycarbonate maintains higher structural integrity by minimizing internal stresses and avoiding material degradation, whereas hot bending softens the polymer, allowing more complex shapes but often causing reduced mechanical strength and increased risk of micro-cracks. Cold bending typically preserves impact resistance and rigidity better than hot bending, which can lead to weakened performance in load-bearing applications. Choosing between cold and hot bending depends on balancing shape complexity with the desired durability and long-term stability of the polycarbonate structure.

Applications for Cold and Hot Bent Polycarbonate

Cold bending polycarbonate is commonly applied in architectural glazing and curved awnings where gradual, low-stress shaping is needed without heat exposure, preserving material clarity and impact resistance. Hot bending allows for complex, tight-radius forms used in automotive components and custom light diffusers, where precise contours and smooth finishes are essential. Both methods support versatile design in construction and industrial applications but differ significantly in process and resultant structural properties.

Choosing the Right Bending Method for Your Project

Cold bending polycarbonate is suitable for gentle curves and requires less energy, preserving the material's optical clarity and structural integrity. Hot bending involves heating the polycarbonate to a pliable temperature, allowing for sharper angles and complex shapes without cracking or stress fractures. Selecting the appropriate method depends on the project's design specifications, desired finish quality, and cost efficiency, with hot bending preferred for intricate bends and cold bending for simpler, large-radius curves.

Cold Bending vs Hot Bending Infographic

materialdif.com

materialdif.com