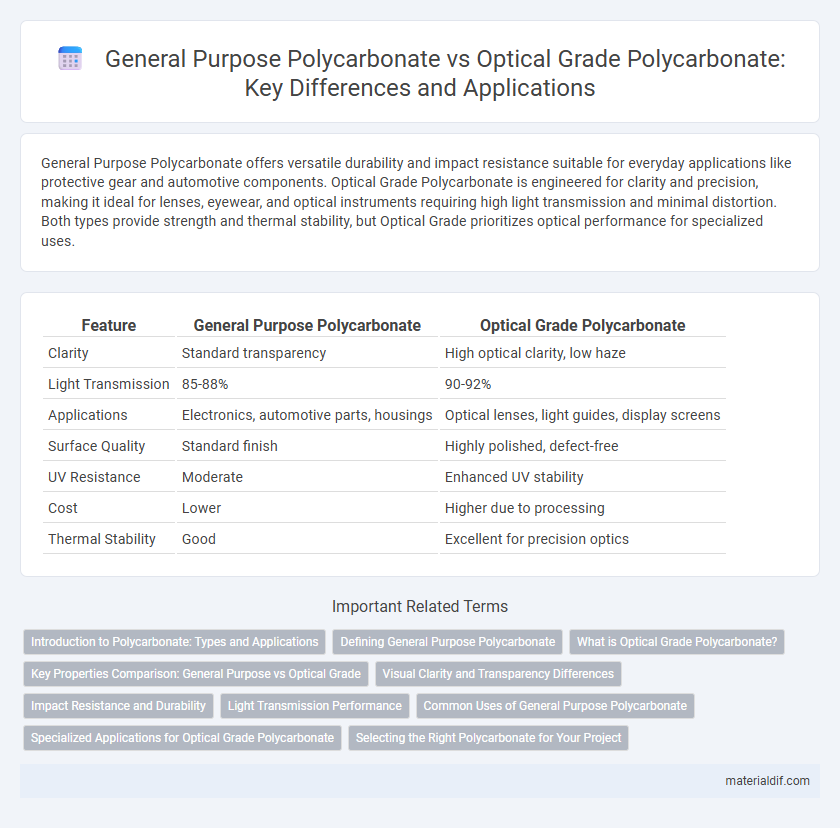

General Purpose Polycarbonate offers versatile durability and impact resistance suitable for everyday applications like protective gear and automotive components. Optical Grade Polycarbonate is engineered for clarity and precision, making it ideal for lenses, eyewear, and optical instruments requiring high light transmission and minimal distortion. Both types provide strength and thermal stability, but Optical Grade prioritizes optical performance for specialized uses.

Table of Comparison

| Feature | General Purpose Polycarbonate | Optical Grade Polycarbonate |

|---|---|---|

| Clarity | Standard transparency | High optical clarity, low haze |

| Light Transmission | 85-88% | 90-92% |

| Applications | Electronics, automotive parts, housings | Optical lenses, light guides, display screens |

| Surface Quality | Standard finish | Highly polished, defect-free |

| UV Resistance | Moderate | Enhanced UV stability |

| Cost | Lower | Higher due to processing |

| Thermal Stability | Good | Excellent for precision optics |

Introduction to Polycarbonate: Types and Applications

General Purpose Polycarbonate offers high impact resistance and thermal stability, making it ideal for automotive parts, electronic housings, and construction materials. Optical Grade Polycarbonate is engineered for superior clarity and low birefringence, essential in precision lenses, medical devices, and optical discs. These distinct grades enable versatile applications by balancing mechanical strength with optical performance requirements.

Defining General Purpose Polycarbonate

General Purpose Polycarbonate (GP-PC) is a versatile thermoplastic known for its excellent impact resistance, transparency, and thermal stability, commonly used in automotive parts, electronic housings, and construction materials. Unlike Optical Grade Polycarbonate, which requires higher purity and superior optical clarity for lenses and light guides, GP-PC offers cost-effective performance with adequate clarity for general industrial applications. Its formulation emphasizes durability and ease of processing rather than the ultra-high optical precision demanded by specialized optical components.

What is Optical Grade Polycarbonate?

Optical grade polycarbonate is a specially formulated variant of polycarbonate designed for high clarity, exceptional light transmission, and minimal distortion, making it ideal for lenses, optical discs, and precision light-guiding applications. Unlike general purpose polycarbonate, which is engineered for impact resistance and toughness in structural uses, optical grade polycarbonate undergoes stringent manufacturing controls to ensure ultra-high purity and surface smoothness. This material excels in applications requiring precise optical performance, such as eyewear lenses, camera components, and medical devices.

Key Properties Comparison: General Purpose vs Optical Grade

General Purpose Polycarbonate offers high impact resistance and excellent dimensional stability, making it suitable for diverse industrial applications, while Optical Grade Polycarbonate provides superior optical clarity with light transmittance exceeding 90%, essential for precision lenses and optical components. Both grades feature high heat resistance, but Optical Grade Polycarbonate maintains minimal birefringence and enhanced UV stability, critical for minimizing visual distortion and ensuring long-term performance in demanding environments. The choice between the two depends on balancing mechanical strength requirements with optical precision and clarity.

Visual Clarity and Transparency Differences

General Purpose Polycarbonate typically exhibits moderate visual clarity with minor haze and lower optical transparency, making it suitable for applications where strength is prioritized over perfect clarity. Optical Grade Polycarbonate is engineered for superior visual clarity and high transparency, offering minimal light distortion and excellent color neutrality, ideal for lenses, medical devices, and optical components. The enhanced purity and refined manufacturing processes of Optical Grade Polycarbonate significantly reduce impurities and birefringence, ensuring optimal light transmission and sharp imaging performance.

Impact Resistance and Durability

General Purpose Polycarbonate offers high impact resistance with excellent durability suitable for everyday applications such as automotive parts and protective gear. Optical Grade Polycarbonate, designed for precision and clarity, maintains superior impact resistance while providing enhanced scratch resistance and durability essential for lenses and optical components. Both grades exhibit exceptional toughness, but Optical Grade Polycarbonate ensures added surface integrity under demanding optical conditions.

Light Transmission Performance

General Purpose Polycarbonate typically offers light transmission rates of around 88-90%, providing clarity suitable for many structural applications. Optical Grade Polycarbonate achieves enhanced light transmission exceeding 92%, optimized for high-precision optical uses such as lenses and light guides. The superior purity and controlled manufacturing process of Optical Grade Polycarbonate minimize haze and distortion, maximizing optical clarity and performance.

Common Uses of General Purpose Polycarbonate

General purpose polycarbonate is widely used in applications requiring durable, impact-resistant materials, such as electronic housings, automotive components, and construction panels. Its excellent mechanical strength and thermal stability make it suitable for consumer goods, including safety helmets and protective eyewear frames. Unlike optical grade polycarbonate, which is tailored for high clarity and precision in lens manufacturing, general purpose polycarbonate prioritizes toughness and versatility across various industrial sectors.

Specialized Applications for Optical Grade Polycarbonate

Optical grade polycarbonate offers superior light transmission and higher optical clarity compared to general purpose polycarbonate, making it ideal for precision lenses, eyewear, and optical discs. Its specialized applications demand stringent control over haze, refractive index, and birefringence, ensuring minimal distortion in advanced imaging and lighting systems. This material's enhanced UV resistance and scratch-resistant coatings further extend its use in high-performance optical devices and automotive headlamps.

Selecting the Right Polycarbonate for Your Project

General Purpose Polycarbonate offers strong impact resistance and high thermal stability suitable for structural applications, while Optical Grade Polycarbonate provides superior clarity and minimal birefringence essential for precision lenses and optical components. Selecting the right polycarbonate depends on project requirements such as mechanical strength versus optical performance, where optical grade excels in transparency and light transmission. Consider factors like UV resistance, surface finish, and dimensional tolerances to ensure that the material meets both functional and aesthetic needs.

General Purpose Polycarbonate vs Optical Grade Polycarbonate Infographic

materialdif.com

materialdif.com