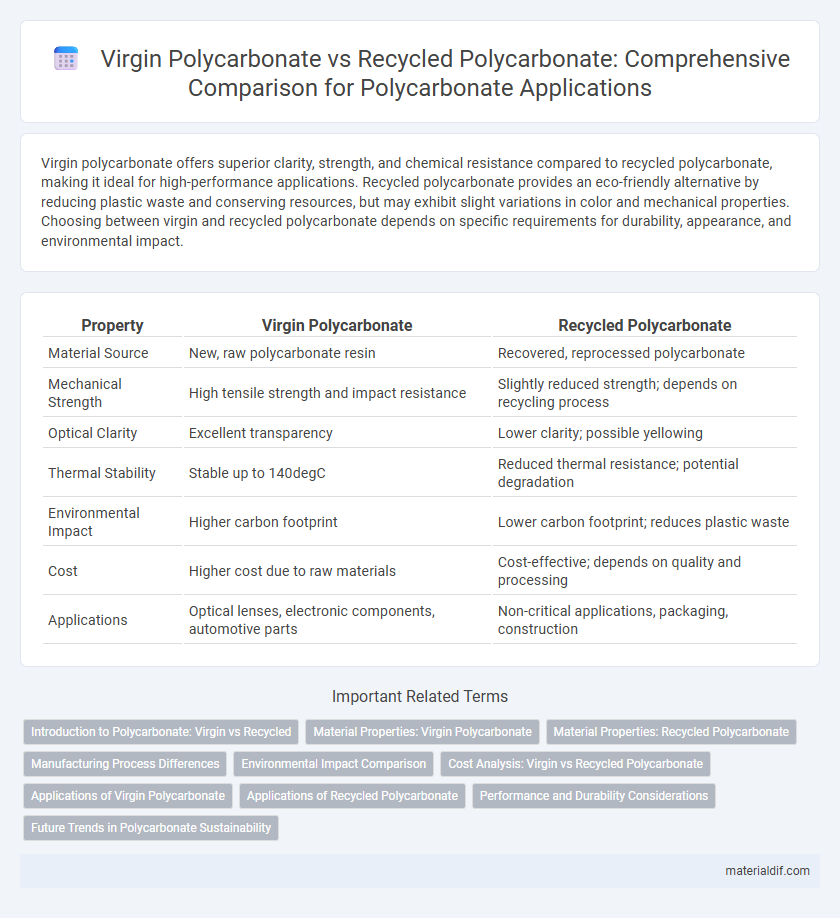

Virgin polycarbonate offers superior clarity, strength, and chemical resistance compared to recycled polycarbonate, making it ideal for high-performance applications. Recycled polycarbonate provides an eco-friendly alternative by reducing plastic waste and conserving resources, but may exhibit slight variations in color and mechanical properties. Choosing between virgin and recycled polycarbonate depends on specific requirements for durability, appearance, and environmental impact.

Table of Comparison

| Property | Virgin Polycarbonate | Recycled Polycarbonate |

|---|---|---|

| Material Source | New, raw polycarbonate resin | Recovered, reprocessed polycarbonate |

| Mechanical Strength | High tensile strength and impact resistance | Slightly reduced strength; depends on recycling process |

| Optical Clarity | Excellent transparency | Lower clarity; possible yellowing |

| Thermal Stability | Stable up to 140degC | Reduced thermal resistance; potential degradation |

| Environmental Impact | Higher carbon footprint | Lower carbon footprint; reduces plastic waste |

| Cost | Higher cost due to raw materials | Cost-effective; depends on quality and processing |

| Applications | Optical lenses, electronic components, automotive parts | Non-critical applications, packaging, construction |

Introduction to Polycarbonate: Virgin vs Recycled

Polycarbonate is a high-performance thermoplastic known for its durability, impact resistance, and transparency, commonly used in automotive parts, electronics, and construction materials. Virgin polycarbonate is produced directly from petrochemical feedstocks, ensuring consistent quality and mechanical properties, while recycled polycarbonate originates from post-consumer or post-industrial waste, promoting sustainability and reducing environmental impact. Comparing virgin and recycled polycarbonate reveals differences in processing stability and potential variations in optical clarity, making selection dependent on specific application requirements and environmental priorities.

Material Properties: Virgin Polycarbonate

Virgin polycarbonate exhibits superior clarity, impact resistance, and UV stability compared to recycled polycarbonate, making it the preferred choice for high-performance applications. Its consistent molecular structure provides enhanced mechanical strength and thermal stability, ensuring durability and long-term reliability. Manufacturers favor virgin polycarbonate for critical uses such as automotive components, optical lenses, and electronic housings where material integrity is paramount.

Material Properties: Recycled Polycarbonate

Recycled polycarbonate retains much of the original material's impact resistance and transparency, making it suitable for many applications requiring durability and clarity. However, recycled polycarbonate can exhibit slight reductions in mechanical strength and thermal stability compared to virgin polycarbonate due to polymer chain degradation during processing. Additives and advanced recycling methods help improve the performance of recycled polycarbonate to meet industry standards for consumer electronics, automotive parts, and packaging.

Manufacturing Process Differences

Virgin polycarbonate undergoes a manufacturing process that starts with raw materials like bisphenol A and phosgene, involving polycondensation to form high-purity polymer chains. In contrast, recycled polycarbonate production incorporates post-consumer or post-industrial waste, which is cleaned, sorted, and reprocessed through melting and extrusion to create usable pellets. The manufacturing process for virgin polycarbonate ensures superior material consistency and mechanical properties, while recycled polycarbonate manufacturing emphasizes energy efficiency and material recovery, often requiring additional steps to remove contaminants and stabilize polymer quality.

Environmental Impact Comparison

Virgin polycarbonate production consumes more energy and generates higher carbon emissions compared to recycled polycarbonate, which significantly reduces environmental footprint by reusing existing materials and minimizing landfill waste. Recycled polycarbonate supports circular economy principles by lowering resource extraction and reducing toxic chemicals associated with raw material processing. Choosing recycled polycarbonate over virgin alternatives helps decrease greenhouse gas emissions and conserves non-renewable resources, making it a more sustainable option for manufacturing.

Cost Analysis: Virgin vs Recycled Polycarbonate

Virgin polycarbonate typically incurs higher production costs due to the use of raw petrochemical materials and energy-intensive manufacturing processes, resulting in a price premium compared to recycled polycarbonate. Recycled polycarbonate offers significant cost savings by utilizing post-consumer or post-industrial waste, reducing material expenses and lowering environmental impact fees. Despite potential variations in mechanical properties, the economic advantages of recycled polycarbonate make it an increasingly attractive option for cost-sensitive applications in electronics and automotive industries.

Applications of Virgin Polycarbonate

Virgin polycarbonate is widely used in high-performance applications such as automotive components, medical devices, and electronic housings due to its superior clarity, strength, and thermal stability. Its consistent quality and contamination-free composition make it ideal for optical lenses, food contact packaging, and safety helmets. The material's excellent impact resistance and dimensional stability ensure reliable performance in demanding environments where recycled alternatives may fall short.

Applications of Recycled Polycarbonate

Recycled polycarbonate is widely utilized in manufacturing automotive components, electrical housings, and consumer electronics casings due to its high impact resistance and thermal stability. Its application in producing sustainable packaging materials and construction elements helps reduce environmental impact while maintaining material performance. Industries increasingly adopt recycled polycarbonate to meet eco-friendly standards without compromising durability and functionality.

Performance and Durability Considerations

Virgin polycarbonate offers superior performance and durability due to its consistent molecular structure and absence of contaminants, resulting in higher impact resistance and clarity. Recycled polycarbonate may exhibit slightly reduced mechanical properties and color stability caused by the degradation during the recycling process. Performance-critical applications typically favor virgin material to ensure long-term reliability and structural integrity.

Future Trends in Polycarbonate Sustainability

Virgin polycarbonate offers superior clarity and strength but has a higher carbon footprint compared to recycled polycarbonate, which supports circular economy initiatives. Innovations in chemical recycling and bio-based feedstocks are driving future trends, enabling high-quality recycled polycarbonate with performance close to virgin material. Increased regulatory pressure and consumer demand for sustainable products accelerate the adoption of recycled polycarbonate in automotive, electronics, and packaging industries.

Virgin Polycarbonate vs Recycled Polycarbonate Infographic

materialdif.com

materialdif.com