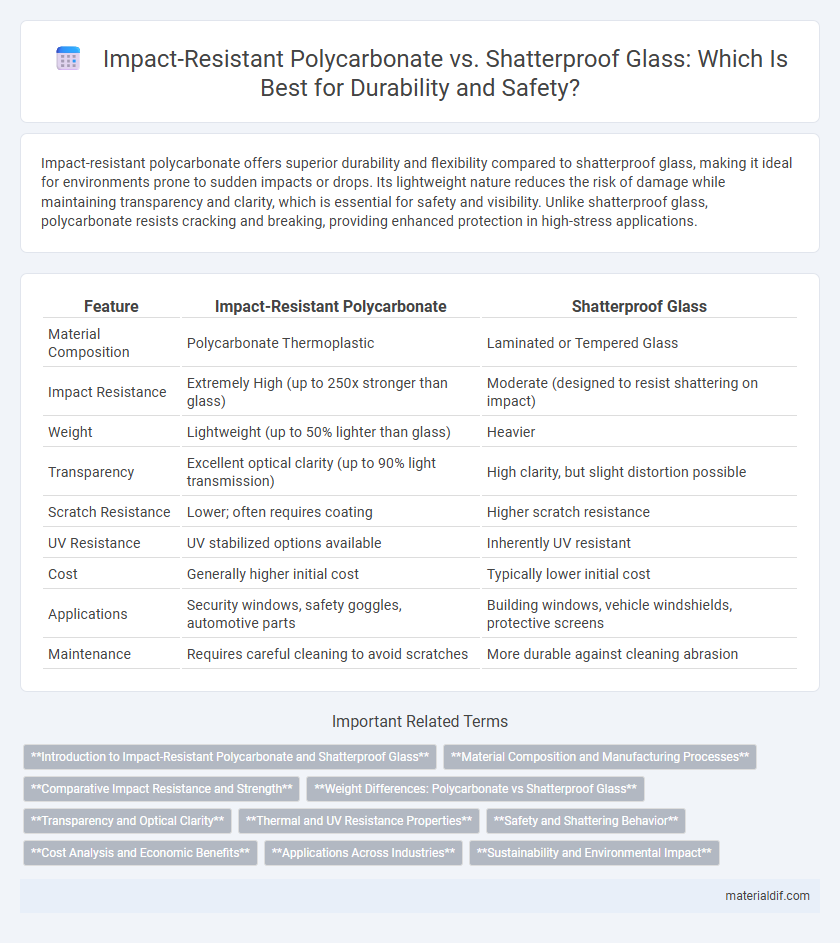

Impact-resistant polycarbonate offers superior durability and flexibility compared to shatterproof glass, making it ideal for environments prone to sudden impacts or drops. Its lightweight nature reduces the risk of damage while maintaining transparency and clarity, which is essential for safety and visibility. Unlike shatterproof glass, polycarbonate resists cracking and breaking, providing enhanced protection in high-stress applications.

Table of Comparison

| Feature | Impact-Resistant Polycarbonate | Shatterproof Glass |

|---|---|---|

| Material Composition | Polycarbonate Thermoplastic | Laminated or Tempered Glass |

| Impact Resistance | Extremely High (up to 250x stronger than glass) | Moderate (designed to resist shattering on impact) |

| Weight | Lightweight (up to 50% lighter than glass) | Heavier |

| Transparency | Excellent optical clarity (up to 90% light transmission) | High clarity, but slight distortion possible |

| Scratch Resistance | Lower; often requires coating | Higher scratch resistance |

| UV Resistance | UV stabilized options available | Inherently UV resistant |

| Cost | Generally higher initial cost | Typically lower initial cost |

| Applications | Security windows, safety goggles, automotive parts | Building windows, vehicle windshields, protective screens |

| Maintenance | Requires careful cleaning to avoid scratches | More durable against cleaning abrasion |

Introduction to Impact-Resistant Polycarbonate and Shatterproof Glass

Impact-resistant polycarbonate offers exceptional durability with high tensile strength and flexibility, making it ideal for environments prone to mechanical stress and impact. Shatterproof glass, often laminated or chemically treated, provides enhanced safety by preventing shards from dispersing upon breakage, commonly used in automotive and architectural applications. Both materials serve critical safety roles, with polycarbonate favored for lightweight, high-impact scenarios and shatterproof glass preferred where optical clarity and resistance to fragmentation are essential.

Material Composition and Manufacturing Processes

Impact-resistant polycarbonate is a thermoplastic polymer composed primarily of bisphenol A and carbonate groups, manufactured through a melt polycondensation process resulting in high molecular weight chains with exceptional toughness. Shatterproof glass typically consists of laminated layers of annealed or tempered glass bonded with a polyvinyl butyral (PVB) interlayer, produced by heat and pressure lamination to enhance safety and reduce fragment dispersion upon impact. The intrinsic molecular flexibility and manufacturing of polycarbonate impart superior impact resistance compared to the brittle, multi-layered structure of shatterproof glass.

Comparative Impact Resistance and Strength

Impact-resistant polycarbonate offers significantly higher impact resistance than shatterproof glass, with the ability to withstand forces up to 250 times greater than standard glass. Polycarbonate's tensile strength ranges between 60-70 MPa, compared to shatterproof glass's typical strength of around 30-40 MPa, enhancing durability in high-impact environments. This superior strength and flexibility make polycarbonate ideal for applications requiring both safety and resilience, such as protective eyewear, vehicle windows, and security barriers.

Weight Differences: Polycarbonate vs Shatterproof Glass

Polycarbonate is significantly lighter than shatterproof glass, with a density of approximately 1.2 g/cm3 compared to glass, which ranges from 2.4 to 2.8 g/cm3. This weight difference makes polycarbonate ideal for applications requiring durability without added bulk, such as automotive windows and protective eyewear. Reduced weight also contributes to easier handling and installation while maintaining impact resistance and safety standards.

Transparency and Optical Clarity

Impact-resistant polycarbonate offers superior transparency and optical clarity compared to shatterproof glass, with light transmittance exceeding 90%, ensuring minimal distortion. Its molecular structure minimizes haze and provides consistent visual performance across various thicknesses, making it ideal for high-clarity applications. Shatterproof glass often compromises clarity due to laminates or coatings, whereas polycarbonate maintains clear visibility under impact stress.

Thermal and UV Resistance Properties

Impact-resistant polycarbonate offers superior thermal resistance, maintaining structural integrity at temperatures ranging from -40degC to 120degC, while shatterproof glass typically withstands moderate heat but is prone to thermal stress and cracking under rapid temperature changes. Polycarbonate exhibits excellent UV resistance when treated with protective coatings, preventing yellowing and degradation, whereas shatterproof glass can lose clarity and weaken over prolonged UV exposure. These properties make impact-resistant polycarbonate more suitable for applications requiring durability against extreme temperature fluctuations and sustained sunlight exposure.

Safety and Shattering Behavior

Impact-resistant polycarbonate exhibits superior safety compared to shatterproof glass due to its high impact strength and flexibility, which prevent catastrophic breakage and reduce the risk of sharp fragments. Unlike shatterproof glass that may crack and splinter under extreme force, polycarbonate absorbs and disperses energy efficiently, maintaining structural integrity. This makes polycarbonate ideal for applications requiring durability and protection against sudden impacts, such as safety shields and vehicle windows.

Cost Analysis and Economic Benefits

Impact-resistant polycarbonate offers a cost-effective alternative to shatterproof glass by providing similar durability at a lower production and installation expense. Polycarbonate's lightweight nature reduces transportation and structural support costs, leading to significant economic savings over time. Long-term benefits include decreased maintenance and replacement expenses due to its superior impact resistance and longer lifespan compared to shatterproof glass.

Applications Across Industries

Impact-resistant polycarbonate is widely utilized across automotive, aerospace, and construction industries due to its exceptional durability and lightweight properties, offering superior impact resistance compared to shatterproof glass. In electronics and protective equipment manufacturing, polycarbonate's high impact strength and thermal stability make it ideal for safety goggles, face shields, and device casings. Shatterproof glass remains dominant in architectural applications where clarity and scratch resistance are critical, but polycarbonate's versatility drives innovation in sectors demanding high-performance, resilient materials.

Sustainability and Environmental Impact

Impact-resistant polycarbonate offers superior sustainability benefits compared to shatterproof glass due to its lightweight composition, which reduces transportation emissions and energy consumption during manufacturing. Polycarbonate is also highly recyclable, enabling repeated reuse without significant degradation of its physical properties, whereas the recycling process for laminated shatterproof glass remains complex and energy-intensive. Its durability minimizes replacement frequency, further decreasing environmental waste and resource depletion relative to glass alternatives.

Impact-resistant Polycarbonate vs Shatterproof Glass Infographic

materialdif.com

materialdif.com