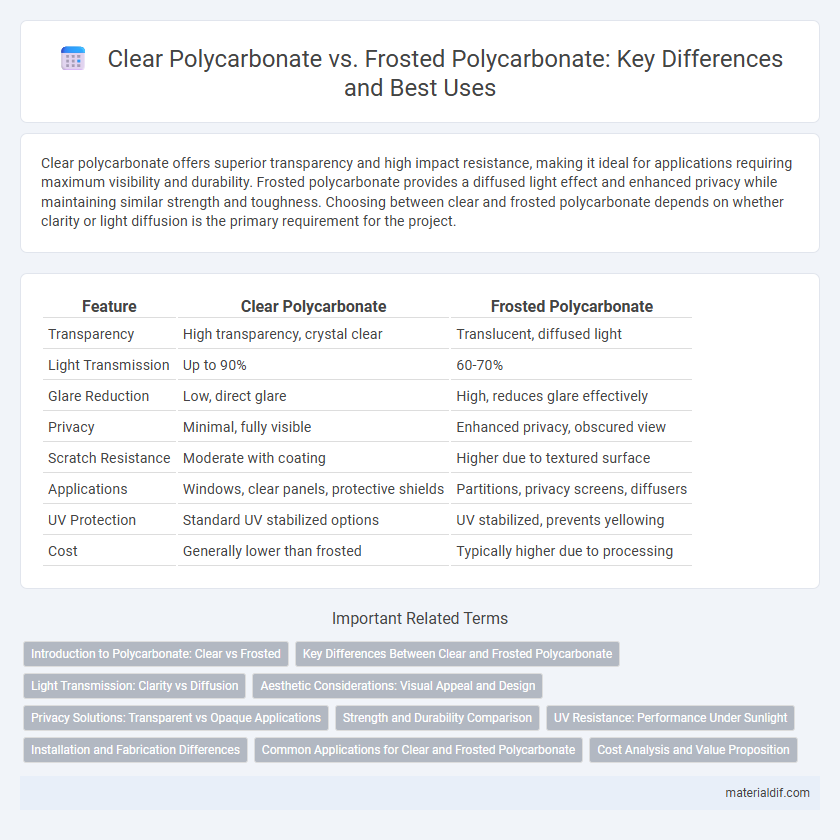

Clear polycarbonate offers superior transparency and high impact resistance, making it ideal for applications requiring maximum visibility and durability. Frosted polycarbonate provides a diffused light effect and enhanced privacy while maintaining similar strength and toughness. Choosing between clear and frosted polycarbonate depends on whether clarity or light diffusion is the primary requirement for the project.

Table of Comparison

| Feature | Clear Polycarbonate | Frosted Polycarbonate |

|---|---|---|

| Transparency | High transparency, crystal clear | Translucent, diffused light |

| Light Transmission | Up to 90% | 60-70% |

| Glare Reduction | Low, direct glare | High, reduces glare effectively |

| Privacy | Minimal, fully visible | Enhanced privacy, obscured view |

| Scratch Resistance | Moderate with coating | Higher due to textured surface |

| Applications | Windows, clear panels, protective shields | Partitions, privacy screens, diffusers |

| UV Protection | Standard UV stabilized options | UV stabilized, prevents yellowing |

| Cost | Generally lower than frosted | Typically higher due to processing |

Introduction to Polycarbonate: Clear vs Frosted

Clear polycarbonate offers high optical clarity and superior light transmission, making it ideal for applications requiring transparency and visual precision. Frosted polycarbonate diffuses light to reduce glare and conceal imperfections while maintaining durability and impact resistance. Both variants exhibit excellent UV resistance and thermal stability, ensuring long-lasting performance across diverse environments.

Key Differences Between Clear and Frosted Polycarbonate

Clear polycarbonate offers superior optical clarity and is ideal for applications requiring maximum light transmission, such as protective shields and transparent barriers. Frosted polycarbonate features a textured surface that diffuses light, reducing glare and enhancing privacy, making it suitable for decorative panels and light-diffusing windows. The choice between clear and frosted polycarbonate depends on the balance between visibility, light diffusion, and privacy requirements in the specific application.

Light Transmission: Clarity vs Diffusion

Clear polycarbonate offers high light transmission with superior clarity, allowing maximum visibility and natural light penetration, ideal for applications requiring transparency and precise visual detail. Frosted polycarbonate diffuses light, reducing glare and providing a softer illumination while maintaining privacy and minimizing shadows. Choosing between clear and frosted polycarbonate depends on the balance needed between light clarity and diffusion for specific architectural or industrial uses.

Aesthetic Considerations: Visual Appeal and Design

Clear polycarbonate offers a sleek, transparent look that enhances brightness and visibility, making it ideal for applications requiring a modern, polished aesthetic. Frosted polycarbonate provides a subtle, diffused appearance that reduces glare and adds a soft, elegant texture, suitable for privacy and decorative purposes. Designers choose between clear and frosted finishes to balance light transmission with visual softness, tailoring the material's appeal to the specific ambiance and style of the space.

Privacy Solutions: Transparent vs Opaque Applications

Clear polycarbonate offers high transparency, making it ideal for applications requiring maximum visibility while maintaining impact resistance. Frosted polycarbonate provides an opaque finish that diffuses light and enhances privacy without sacrificing strength, suitable for partitions, bathroom enclosures, and office dividers. Choosing between clear and frosted polycarbonate depends on the balance between desired visibility and privacy needs in architectural or interior design projects.

Strength and Durability Comparison

Clear polycarbonate offers exceptional impact resistance and high tensile strength, making it ideal for applications requiring maximum durability and transparency. Frosted polycarbonate, while slightly less transparent, maintains comparable strength and provides enhanced surface scratch resistance due to its textured finish. Both materials exhibit excellent UV resistance and weatherability, ensuring long-term performance in demanding environments.

UV Resistance: Performance Under Sunlight

Clear polycarbonate offers excellent UV resistance, maintaining high transparency and structural integrity under prolonged sunlight exposure. Frosted polycarbonate also provides strong UV protection but diffuses light more effectively, reducing glare and enhancing privacy in outdoor applications. Both types incorporate UV stabilizers to prevent yellowing and degradation, ensuring durability in UV-intensive environments.

Installation and Fabrication Differences

Clear polycarbonate offers superior light transmission and smooth surface finish, making it ideal for applications requiring high clarity and aesthetics, while its fabrication demands careful handling to prevent surface scratches. Frosted polycarbonate diffuses light, reducing glare and concealing imperfections, facilitating easier cutting and shaping with less visual impact from minor surface defects. Installation of clear sheets often necessitates protective films and precise alignment for optical clarity, whereas frosted panels allow more flexible positioning, tolerating slight imperfections during mounting without compromising appearance.

Common Applications for Clear and Frosted Polycarbonate

Clear polycarbonate is widely used in applications requiring high transparency and impact resistance, such as safety glazing, automotive windshields, and protective barriers. Frosted polycarbonate is favored for privacy and diffused light transmission, making it ideal for partitions, skylights, and decorative panels. Both materials are essential in construction, electronics, and signage for their durability and versatile light management.

Cost Analysis and Value Proposition

Clear polycarbonate typically commands a higher price due to its superior light transmission and aesthetic appeal, making it ideal for applications requiring transparency and visual clarity. Frosted polycarbonate offers a cost-effective alternative with enhanced privacy and light diffusion, reducing glare while maintaining durability. The value proposition hinges on selecting clear polycarbonate for premium optical performance and frosted polycarbonate for budget-conscious projects where privacy and reduced glare are prioritized.

Clear Polycarbonate vs Frosted Polycarbonate Infographic

materialdif.com

materialdif.com