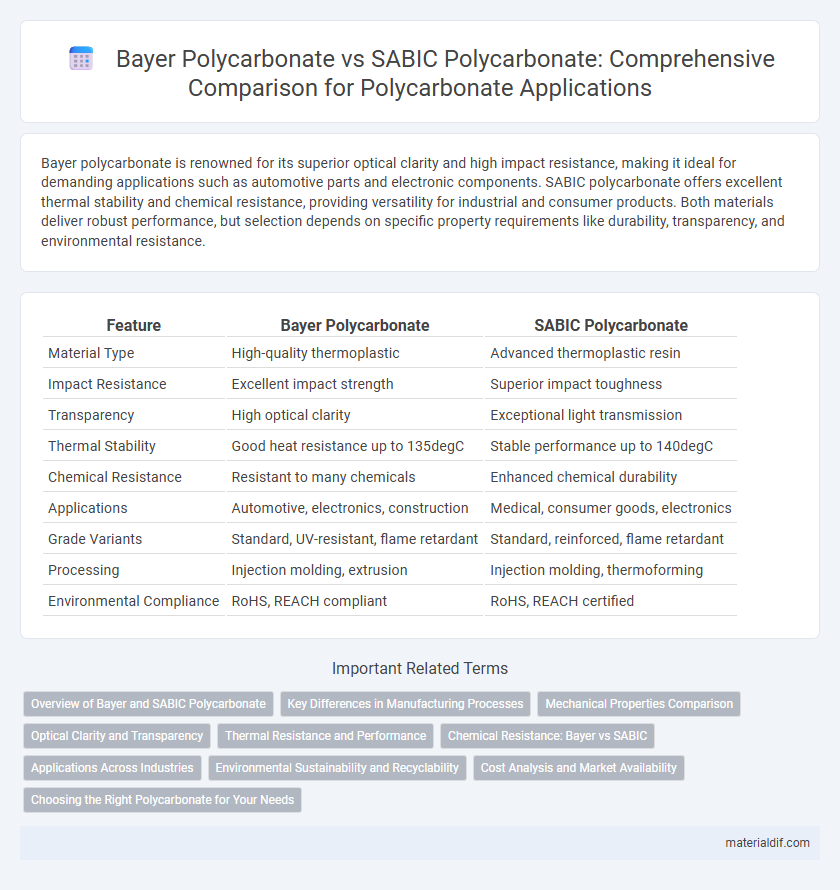

Bayer polycarbonate is renowned for its superior optical clarity and high impact resistance, making it ideal for demanding applications such as automotive parts and electronic components. SABIC polycarbonate offers excellent thermal stability and chemical resistance, providing versatility for industrial and consumer products. Both materials deliver robust performance, but selection depends on specific property requirements like durability, transparency, and environmental resistance.

Table of Comparison

| Feature | Bayer Polycarbonate | SABIC Polycarbonate |

|---|---|---|

| Material Type | High-quality thermoplastic | Advanced thermoplastic resin |

| Impact Resistance | Excellent impact strength | Superior impact toughness |

| Transparency | High optical clarity | Exceptional light transmission |

| Thermal Stability | Good heat resistance up to 135degC | Stable performance up to 140degC |

| Chemical Resistance | Resistant to many chemicals | Enhanced chemical durability |

| Applications | Automotive, electronics, construction | Medical, consumer goods, electronics |

| Grade Variants | Standard, UV-resistant, flame retardant | Standard, reinforced, flame retardant |

| Processing | Injection molding, extrusion | Injection molding, thermoforming |

| Environmental Compliance | RoHS, REACH compliant | RoHS, REACH certified |

Overview of Bayer and SABIC Polycarbonate

Bayer polycarbonate, branded as Makrolon, is renowned for its high impact resistance, excellent optical clarity, and UV stability, making it ideal for applications in automotive, electronics, and construction industries. SABIC polycarbonate, marketed under the Lexan name, offers superior dimensional stability, flame retardancy, and chemical resistance, widely used in medical devices, lighting, and consumer electronics. Both Bayer and SABIC are global leaders in polycarbonate production, focusing on innovation, sustainability, and tailored solutions to meet diverse industrial requirements.

Key Differences in Manufacturing Processes

Bayer polycarbonate is produced using a continuous melt polycondensation process, which offers high molecular weight and excellent optical clarity. SABIC polycarbonate employs a solution polymerization method, allowing better control over molecular structure and enhanced toughness. The differences in these manufacturing techniques result in distinct performance characteristics, with Bayer excelling in transparency and SABIC providing improved impact resistance.

Mechanical Properties Comparison

Bayer polycarbonate exhibits superior impact resistance and higher tensile strength compared to SABIC polycarbonate, making it ideal for high-stress applications. SABIC polycarbonate offers enhanced flexural modulus and better thermal stability, providing advantages in environments requiring dimensional stability under heat. Both materials deliver excellent mechanical properties, but the choice depends on specific performance requirements such as impact toughness or thermal endurance.

Optical Clarity and Transparency

Bayer Polycarbonate exhibits superior optical clarity with light transmittance rates typically above 90%, making it ideal for applications requiring high transparency such as eyewear lenses and medical devices. SABIC Polycarbonate also offers excellent transparency but often emphasizes enhanced impact resistance and UV stability, slightly compromising the absolute clarity compared to Bayer. Both materials provide durable and clear solutions; however, Bayer is preferred when maximum optical performance is critical.

Thermal Resistance and Performance

Bayer polycarbonate exhibits exceptional thermal resistance with a continuous use temperature of up to 135degC, making it ideal for applications requiring high heat endurance. SABIC polycarbonate offers competitive performance, featuring excellent impact strength and dimensional stability at elevated temperatures up to 120degC. In comparison, Bayer polycarbonate generally outperforms SABIC in thermal resistance, while SABIC provides a cost-effective balance of performance and durability.

Chemical Resistance: Bayer vs SABIC

Bayer polycarbonate demonstrates superior chemical resistance against common solvents such as acetone and isopropanol compared to SABIC polycarbonate, making it more suitable for applications requiring high durability. SABIC polycarbonate offers moderate resistance but tends to exhibit surface degradation and stress cracking under prolonged chemical exposure. The chemical stability of Bayer polycarbonate ensures enhanced longevity in harsh chemical environments, delivering better performance in demanding industrial uses.

Applications Across Industries

Bayer polycarbonate is widely recognized for its superior clarity and impact resistance, making it ideal for automotive headlamp lenses, electronic housings, and medical devices requiring sterilization. SABIC polycarbonate excels in high-performance applications such as electrical connectors, optical media, and household appliances due to its excellent thermal stability and chemical resistance. Both materials serve diverse industries, but Bayer is preferred in optical and medical fields, while SABIC dominates in electrical and consumer goods sectors.

Environmental Sustainability and Recyclability

Bayer polycarbonate emphasizes environmentally sustainable production through the use of renewable raw materials and energy-efficient processes, reducing carbon footprint significantly. SABIC polycarbonate prioritizes recyclability by advancing chemical recycling technologies that enable closed-loop material recovery, enhancing circular economy potential. Both companies implement robust sustainability frameworks but differ in their strategic focus on raw material innovation versus end-of-life material management.

Cost Analysis and Market Availability

Bayer Polycarbonate generally commands a premium price due to its consistent high quality and established brand reputation, making it a preferred choice for high-performance applications. SABIC Polycarbonate offers more competitive pricing and broader market availability, benefiting from its extensive global manufacturing network and diversified product portfolio. Cost analysis reveals that SABIC's lower prices and widespread supply chain presence provide greater accessibility for large-scale industrial use, whereas Bayer's products are favored in specialized markets requiring stringent performance standards.

Choosing the Right Polycarbonate for Your Needs

Bayer Polycarbonate offers superior optical clarity and high impact resistance, making it ideal for applications requiring transparency and toughness, such as automotive lenses and electronic displays. SABIC Polycarbonate is preferred for its excellent thermal stability and chemical resistance, suitable for industrial components exposed to harsh environments. Selecting between Bayer and SABIC polycarbonate depends on balancing factors like mechanical strength, environmental exposure, and application-specific performance requirements.

Bayer Polycarbonate vs SABIC Polycarbonate Infographic

materialdif.com

materialdif.com