Polycarbonate sheets provide superior impact resistance and rigidity, making them ideal for structural applications such as roofing, glazing, and protective barriers. In contrast, polycarbonate films offer flexibility and lightweight properties, suitable for lamination, electronic displays, and solar panel encapsulation. Choosing between polycarbonate sheet and film depends on the required durability, thickness, and application constraints.

Table of Comparison

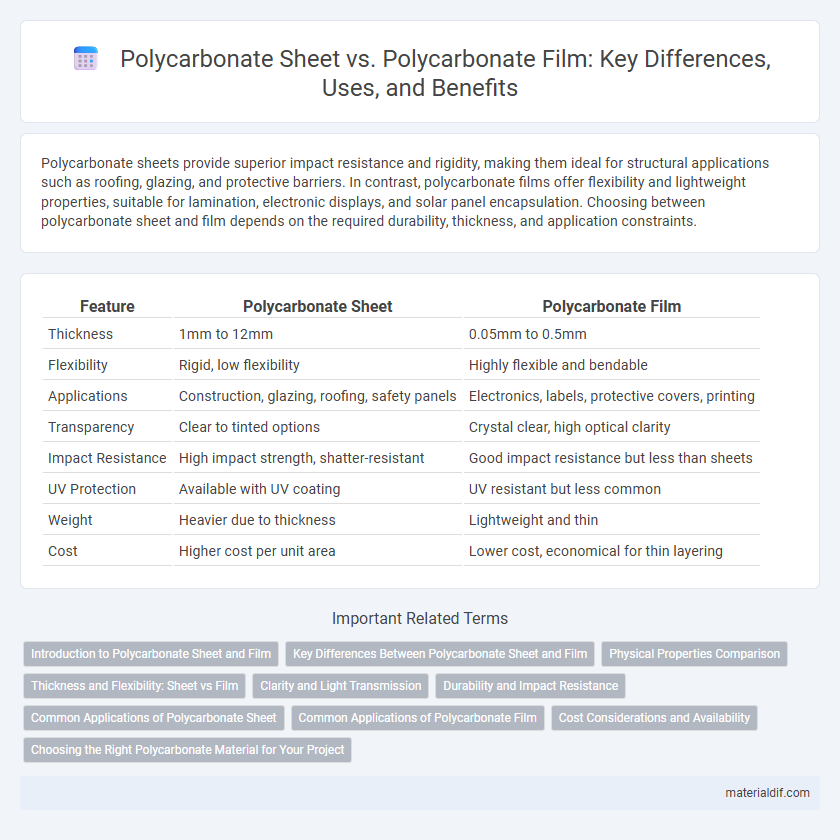

| Feature | Polycarbonate Sheet | Polycarbonate Film |

|---|---|---|

| Thickness | 1mm to 12mm | 0.05mm to 0.5mm |

| Flexibility | Rigid, low flexibility | Highly flexible and bendable |

| Applications | Construction, glazing, roofing, safety panels | Electronics, labels, protective covers, printing |

| Transparency | Clear to tinted options | Crystal clear, high optical clarity |

| Impact Resistance | High impact strength, shatter-resistant | Good impact resistance but less than sheets |

| UV Protection | Available with UV coating | UV resistant but less common |

| Weight | Heavier due to thickness | Lightweight and thin |

| Cost | Higher cost per unit area | Lower cost, economical for thin layering |

Introduction to Polycarbonate Sheet and Film

Polycarbonate sheets are rigid, durable materials widely used in construction, glazing, and automotive applications due to their high impact resistance and thermal insulation properties. Polycarbonate films, by contrast, are thin, flexible layers often utilized for protective coatings, electronic displays, and optical lamination. Both forms of polycarbonate provide excellent transparency and UV resistance, making them versatile solutions across diverse industries.

Key Differences Between Polycarbonate Sheet and Film

Polycarbonate sheets are rigid, thick, and durable, designed for structural applications like glazing, roofing, and protective barriers, while polycarbonate films are thin, flexible, and primarily used for laminations, window tints, and electronic display protection. Sheets offer high impact resistance and thermal insulation, whereas films provide excellent optical clarity and scratch resistance but lack structural strength. The manufacturing processes differ significantly: sheets are extruded or cast for solid panels, while films are produced through extrusion or casting in very thin layers for versatile surface applications.

Physical Properties Comparison

Polycarbonate sheets demonstrate superior impact resistance and rigidity compared to polycarbonate films, making them suitable for structural applications and protective barriers. While polycarbonate films offer greater flexibility and thinness, allowing for conformability on various surfaces, their tensile strength and hardness are lower than those of sheets. Thickness ranges from 0.75 to 12 mm for sheets and 50 to 300 microns for films, influencing durability and application scope in industries like construction and electronics.

Thickness and Flexibility: Sheet vs Film

Polycarbonate sheets typically range from 0.75mm to over 12mm in thickness, offering rigid structural support for applications requiring durability and impact resistance. Polycarbonate films, usually between 0.05mm and 0.5mm thick, provide enhanced flexibility, making them ideal for wrapping, laminating, or lightweight protective layers. The thickness differential directly influences flexibility, with thinner polycarbonate films bending easily without cracking, whereas thicker polycarbonate sheets maintain shape under stress but allow minimal flex.

Clarity and Light Transmission

Polycarbonate sheets offer superior clarity and higher light transmission rates compared to polycarbonate films, making them ideal for applications requiring maximum visibility and natural light penetration. While polycarbonate films provide adequate transparency, their thinner structure often results in reduced light transmission and slightly lower optical clarity. The rigid nature of polycarbonate sheets ensures minimal distortion, enhancing visual performance in glazing and protective cover applications.

Durability and Impact Resistance

Polycarbonate sheets offer superior durability and impact resistance compared to polycarbonate films, making them ideal for applications requiring structural strength and long-term performance. Sheets provide enhanced thickness and rigidity, enabling better protection against impacts, weather, and UV exposure. In contrast, polycarbonate films are thinner, more flexible, and suitable for applications needing lightweight protection but offer less resistance to heavy impacts or prolonged wear.

Common Applications of Polycarbonate Sheet

Polycarbonate sheets are widely used in architectural glazing, skylights, and safety glazing due to their high impact resistance and excellent transparency. They serve in the construction industry for roofing, greenhouses, and protective barriers, offering durability and UV protection. Unlike polycarbonate films, sheets provide structural strength suitable for load-bearing applications.

Common Applications of Polycarbonate Film

Polycarbonate film is commonly used in optical lenses, solar control glazing, and protective covers due to its high impact resistance and excellent transparency. Its flexibility and thin profile make it ideal for electronic displays, touchscreens, and flexible circuits. Unlike polycarbonate sheets, films are preferred for applications requiring lightweight, durable, and flexible material solutions.

Cost Considerations and Availability

Polycarbonate sheets generally have a higher upfront cost compared to polycarbonate films, reflecting their thickness and durability for structural applications. Polycarbonate films offer a more affordable option for lightweight, flexible uses but may require replacement more frequently, impacting long-term expenses. Availability varies with sheets widely stocked in construction and industrial supply chains, while films are more common in packaging and protective overlays, influencing procurement decisions based on project scale and budget constraints.

Choosing the Right Polycarbonate Material for Your Project

Polycarbonate sheets offer superior rigidity and impact resistance, making them ideal for structural applications such as glazing and protective barriers. Polycarbonate films provide flexibility and lightweight properties suited for laminating, shading, or decorative purposes. Selecting the right polycarbonate material depends on project requirements like durability, transparency, thickness, and whether flexibility or hardness is prioritized.

Polycarbonate Sheet vs Polycarbonate Film Infographic

materialdif.com

materialdif.com